Heating method of heating furnace for glass tempering

A heating method and heating furnace technology, which are applied in glass tempering, glass production, glass manufacturing equipment and other directions, can solve the problems of blocking radiant heat, speeding up the heating rate of the glass to be processed, and the long radiation distance of the electric heating element. The effect of heating speed, saving time cost and processing cost, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

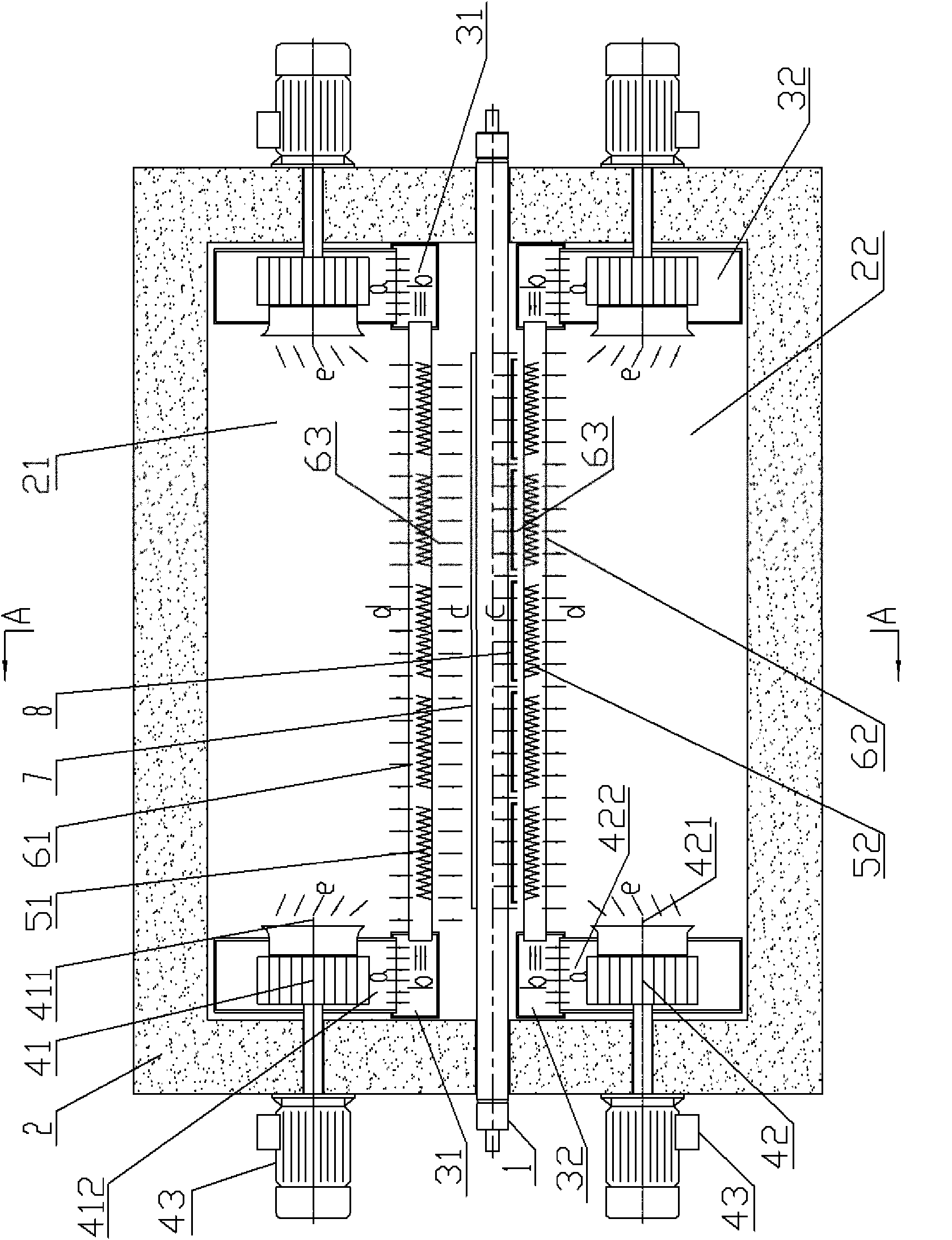

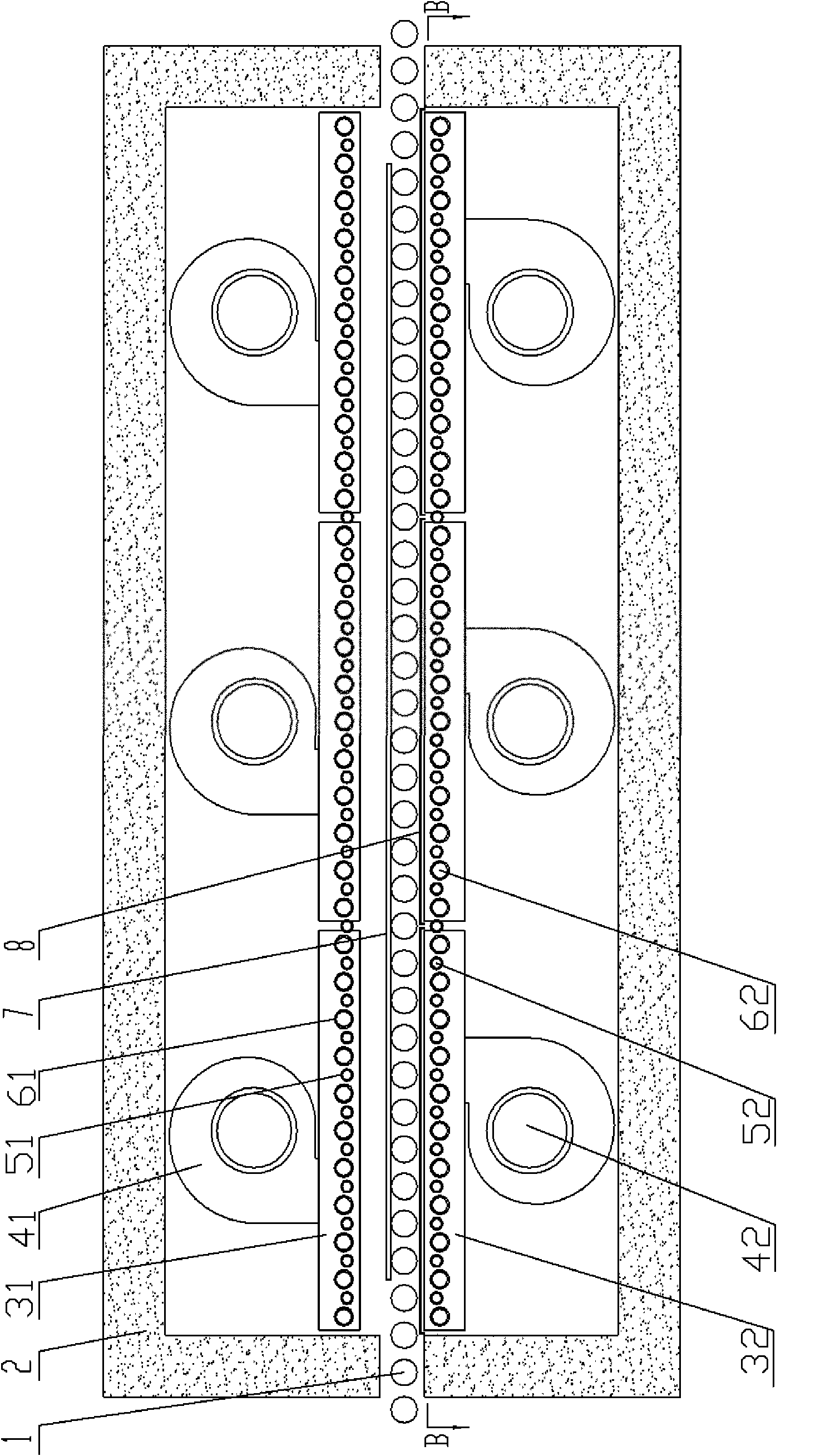

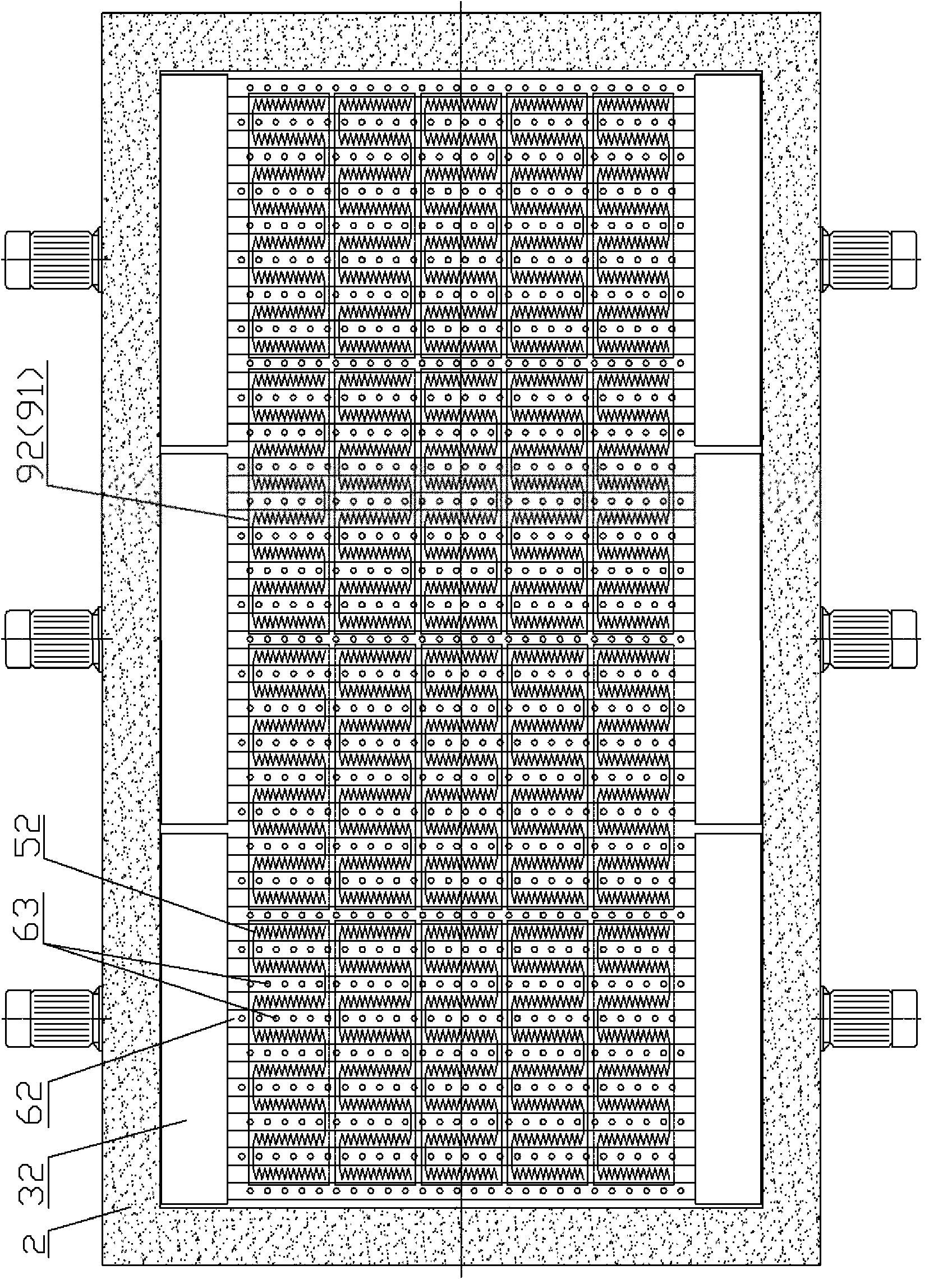

[0026] see figure 1 , figure 2 , image 3 , a kind of heating furnace for glass tempering provided by the present invention has a furnace body 2, and a closed heating space is formed in the furnace body 2 (comprising frame and insulation material);

[0027] On a horizontal plane in the heating space of the furnace body 2, a plurality of horizontal roller tables 1 are arranged at intervals, and the two ends of each horizontal roller table 1 are all rotatably supported on the outer sides of the furnace body 2; when the present invention works, it is located The glass to be processed 7 of different shapes and areas on the horizontal roller table 1 separates the heating space into a relatively closed and disconnected upper space 21 and a lower space 22;

[0028] Several upper high-temperature fans 41 and lower high-temperature fans 42 are arranged in the upper space 21 and the lower space 22 respectively. The driving device 43 (such as an electric motor or an internal combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com