Power type high-current device mounting process

A high-current, power-type technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of large package chip area, influence on subsequent processing, uneven heat dissipation, etc., achieve uniform solder thickness, prevent oxidation, Effect of improving heat dissipation and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

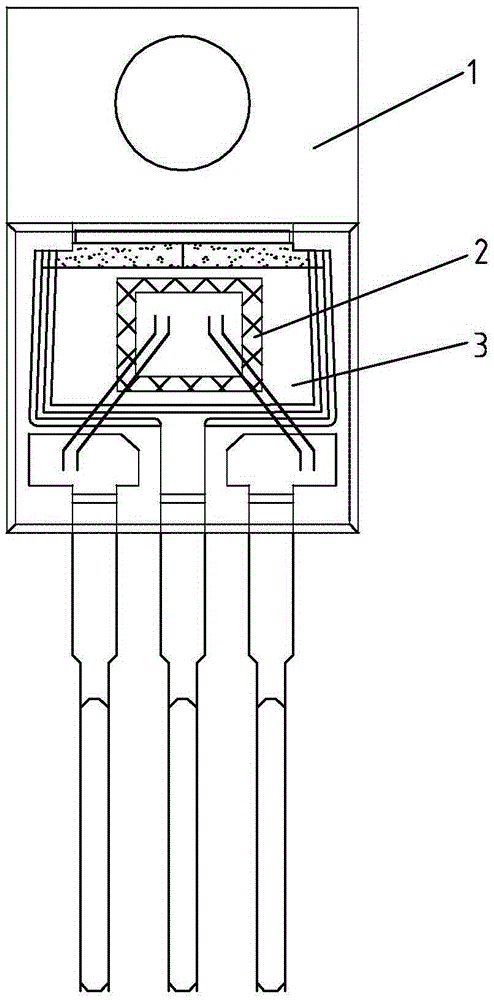

[0027] Such as figure 1 As shown, a power-type high-current device chip mounting process, the process uses a temperature track with a temperature rise area, a temperature stable area and a temperature drop area, and the steps of the process are as follows:

[0028] (a) sending the device frame 1 into the heating area for heat treatment;

[0029] (b) Then the device frame 1 is sent into the temperature stable area, and the solder is spot welded on the PAD area of the device frame 1; the spot welding length of the solder can be selected automatically;

[0030] (c) In the temperature stable area, use a die head to trim the solder on the PAD area of the device frame 1 into a "mouth"-shaped structure with a certain height that matches the chip size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com