Electromagnetic adsorption type ultrasonic flaw detection robot

An ultrasonic flaw detection and adsorption technology, which is used in the analysis of solids, motor vehicles, transportation and packaging using sonic/ultrasonic/infrasonic waves. It can solve the problems of high labor intensity and low efficiency of manual flaw detection. Ups and downs, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail:

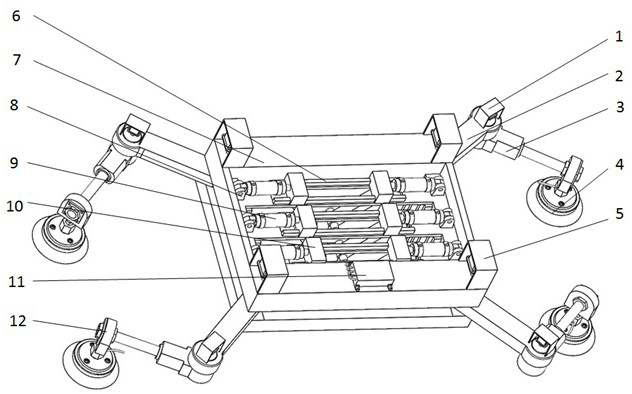

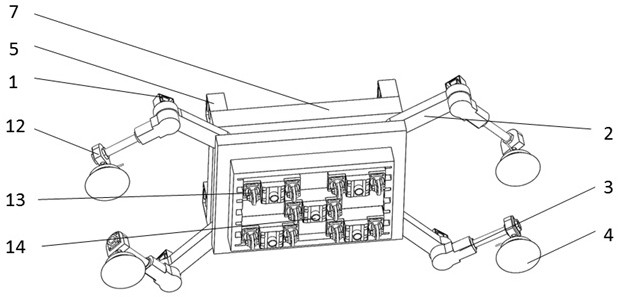

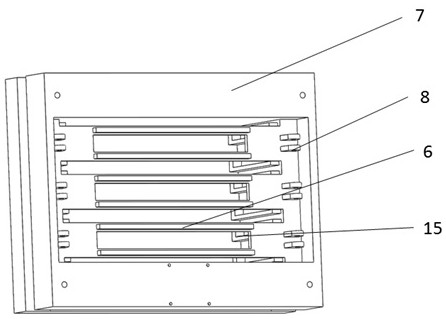

[0031] Such as Figure 1 to Figure 5 As shown, an electromagnetic adsorption ultrasonic flaw detection robot includes a carrying frame 7, a crawling mechanism, a pressing mechanism, and also includes controlled wires and control units.

[0032] The carrying frame 7 is used to install the crawling mechanism and the hold-down mechanism, such as figure 1 As shown, four first servo joint motors 5 are respectively installed on the four corners of the upper end surface of the carrier frame 7 . Simultaneously, the upper end surface of the carrying frame 7 is provided with a power supply 11, such as Figure 4 As shown, the power supply 11 is connected to the four electromagnetic chucks 4 through wires 19, and the control unit on the carrying frame controls the on-off of the power supply 11, thereby controlling the adsorption or detachment of the electromagnetic chucks 4 on the crawlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com