Reinforced material

A technology of reinforcing materials and reinforcing fibers, applied in the field of anti-invasive roll-type barriers, can solve the problems of difficult installation, rigid barriers, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

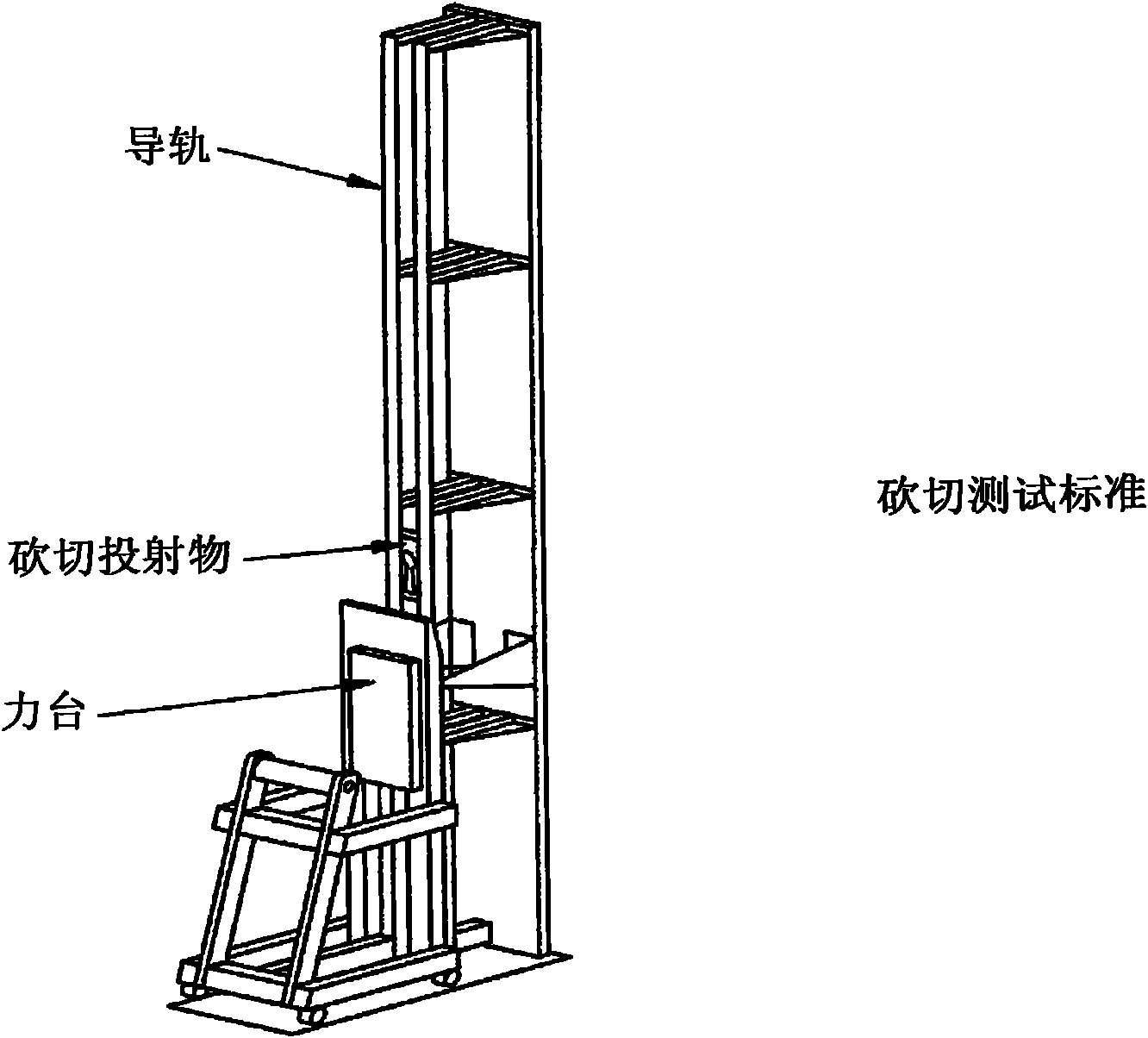

[0042] Anti-invasive fabrics were tested according to the standard "HOSDB Slash Resistance Standard for UK Police (2006)" Publication No. 48 / 05 (which is incorporated herein by reference).

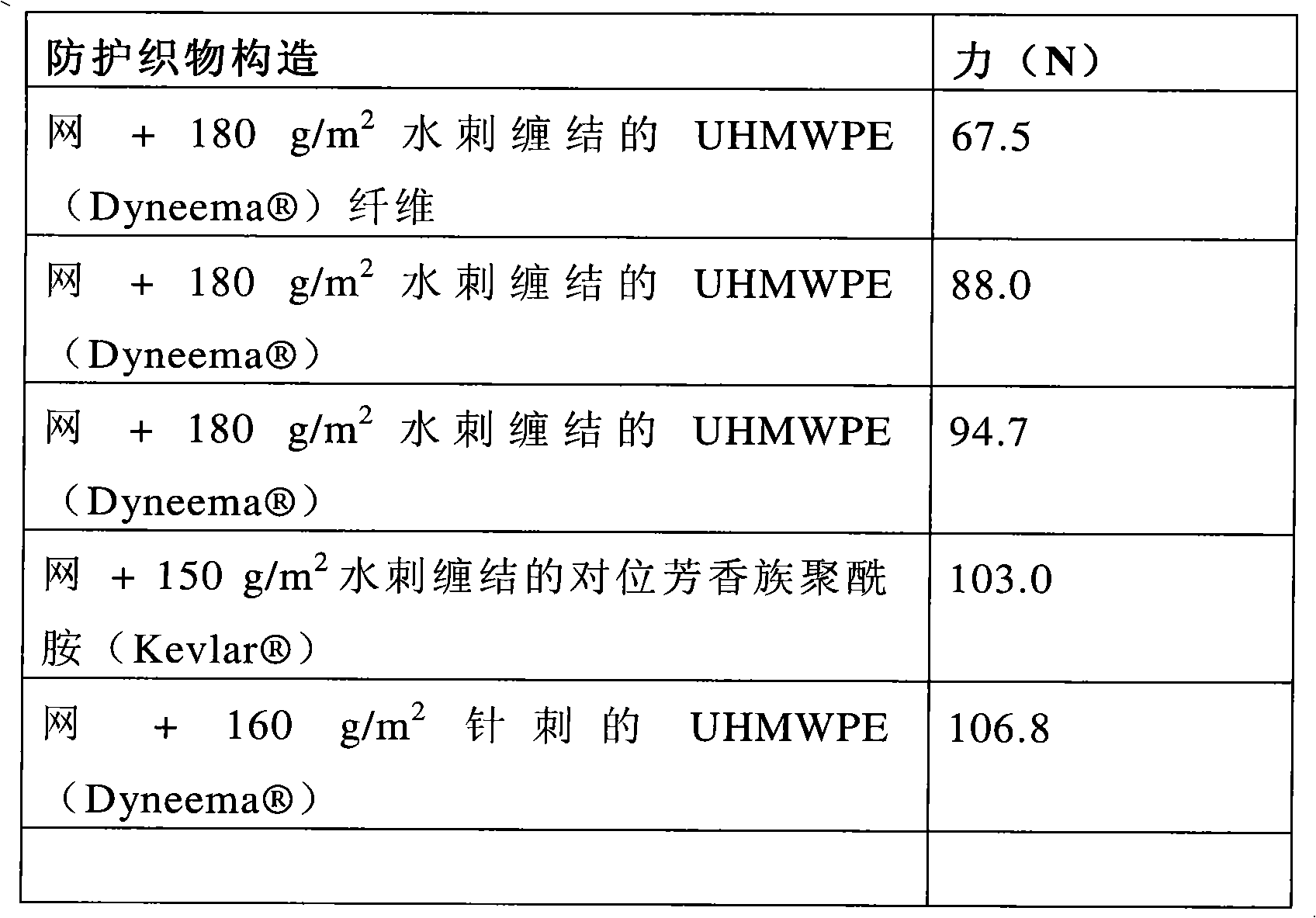

[0043] Guided landing devices designed using HOSDB (such as figure 1 shown) was tested on an external stand-alone facility. This device enables the chopping projectile to fall under the influence of gravity and contact a predetermined point of the chopping plate, which is arranged on a force platform installed at an angle of 2° to the vertical. Appendix A of the standard "HOSDB Slash Resistance Standard for UK Police (2006)" Publication No. 48 / 05 gives details of the setup and calibration of the test equipment for calibration tests on HOSDB certified test equipment. Examples of test data obtained using fabrics produced according to the invention under different process conditions are listed in Table 1a. Reference data obtained with fabrics produced without the use of knitted wire mesh ar...

example 2

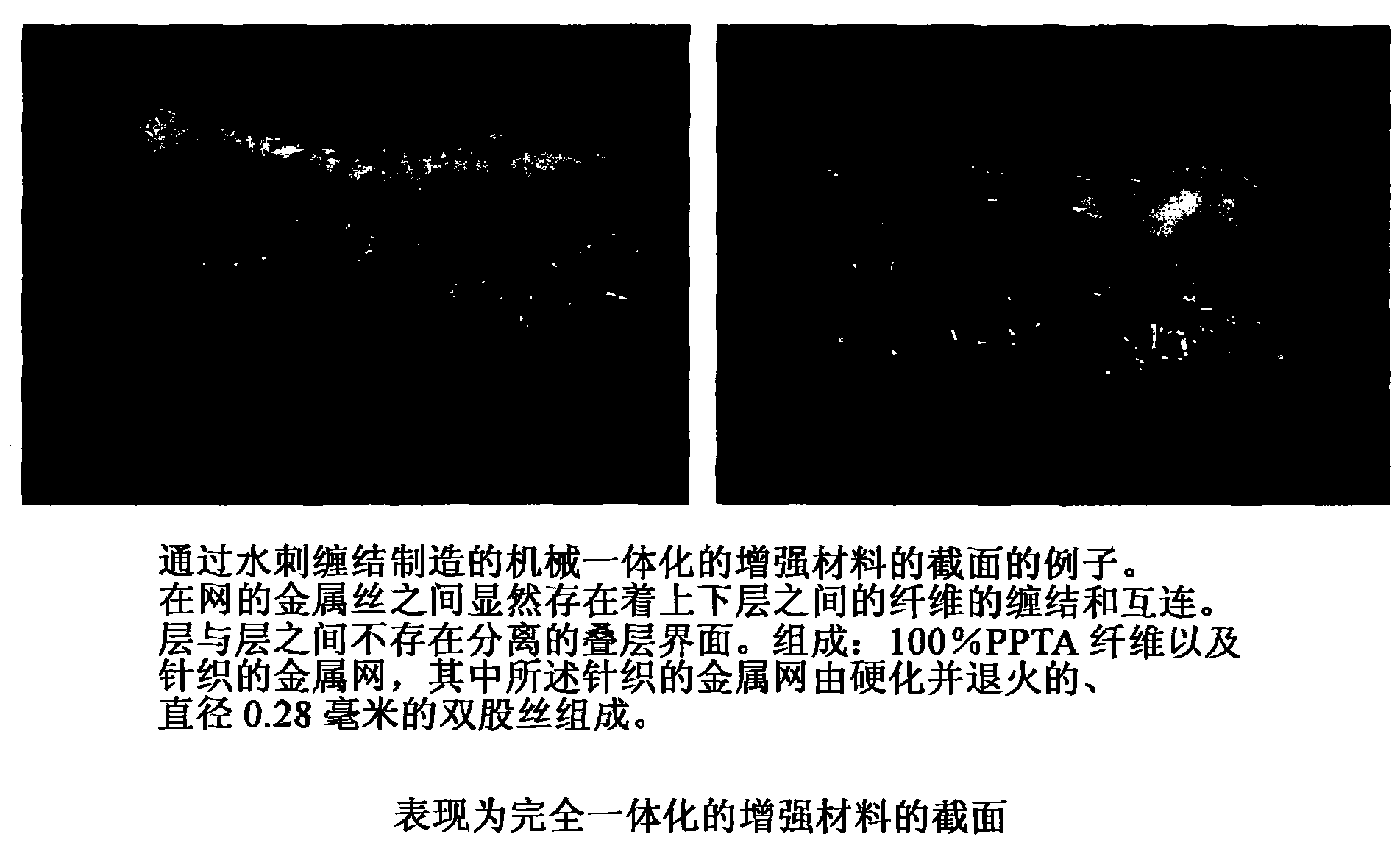

[0049] Two carded and cross-laid webs were prepared from 100% PPTA fibers (para-aramid) and placed on either side of a knitted metal mesh made of hardened and annealed, Composed of twin strands with a diameter of 0.28 mm. The area density of the first fiber layer is 50g / m 2 , the areal density of the second fiber layer is 150g / m 2 . The surface density of the knitted metal mesh layer is 1800g / m 2 , which consists of annealed and hardened twin strands. After pre-wetting to evacuate the air in the fibrous layer, the above-mentioned three-layer construction was hydroentangled using 5 jets with a certain water jet pressure profile, where the maximum pressure was 220 bar (2.2 MPa). Dry the fabric in a through air dryer. The cut resistance of the resulting fabrics was tested at an independent facility according to EN388:2003 (6.2 Knife edge cut resistance) and EN ISO 13997:1999. The blade type used was GRU-GRU88-0121 and the sharpness correction factors were 0.839 and 0.822. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com