Integrated density gradient thermal protection material and preparation method thereof

A heat protection material and density gradient technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem that the temperature resistance and reliability of adhesives affect the thermal protection effect and cannot be applied to aircraft Problems such as thermal protection and long molding process cycle are beneficial to large-scale application, ensuring long-term use effect and reducing the risk of delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] According to another embodiment, there is also provided a method for preparing the above-mentioned integrated density gradient thermal protection material, which includes the following steps:

[0049] Step 1, preparing the reinforcement, including:

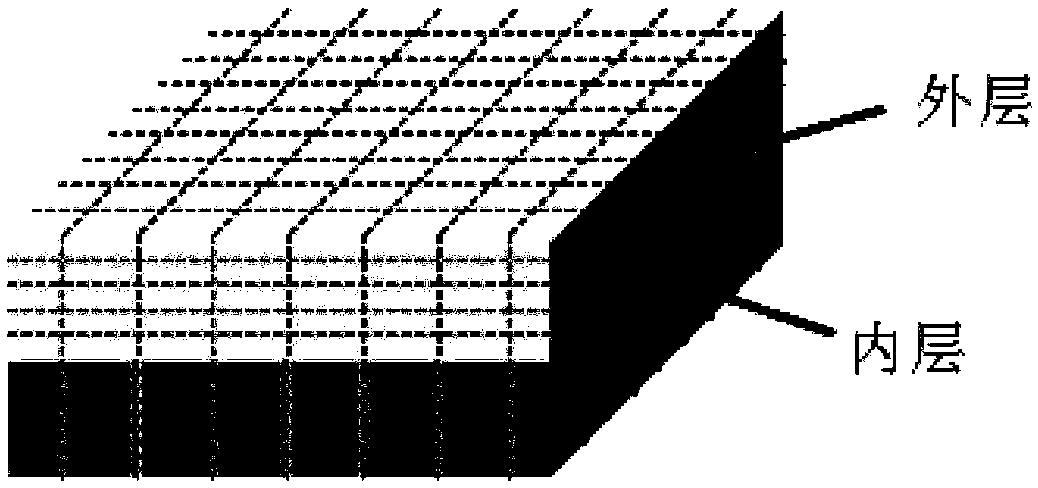

[0050] Lay a set number of layers of chopped fiber mesh tires in the mold and perform needle punching to obtain a fiber reinforced inner layer; continue laying a set number of layers of 2.5D braided fabric or thick fiber fabric on the fiber reinforced inner layer for needle punching , to obtain the fiber-reinforced outer layer;

[0051] Step 2, preparing matrix raw materials, including:

[0052] Prepare a solution of polymeric elastomer or low molecular weight polymer of ablative resin and appropriate amount of solvent mixture;

[0053] Step 3, heat protection material molding, including:

[0054] The solution is injected into the reinforcing body, so that the reinforcing body is fully infiltrated with the solution; and ...

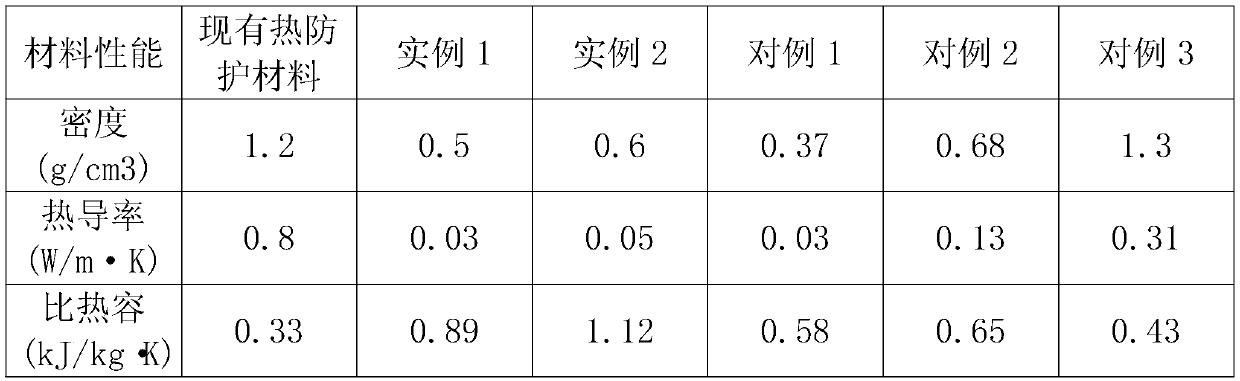

Embodiment 1

[0065] Determine the preferred range of one-piece thermal protection composite material reinforcements with a density of 3mm in thickness and a density of 1.0g / cm 3 The 2.5D quartz fiber fabric has a combined thickness of 12mm and a density of 0.12g / cm 3 Chopped quartz fiber mesh tire, the injected matrix resin has a density of 0.3g / cm 3 Silicone-modified phenolic resin, using RTM liquid molding process, cured at 80°C for 20 hours to form a density gradient thermal protection material.

Embodiment 2

[0067] The reinforcement body of the integrated density gradient thermal protection material has a thickness of 1mm and a density of 0.5g / cm 3 The high-density quartz fiber cloth has a thickness of 1mm and a density of 0.3g / cm 3 The thickness of the quartz fiber cloth is 13mm and the density is 0.12g / cm 3 Low-density chopped quartz fiber mesh tire, the injected matrix resin has a density of 0.2g / cm 3 Silicone-modified phenolic resin, using RTM liquid molding process, cured at 120°C for 12 hours to form an integrated density gradient thermal protection material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com