Encapsulation structure and electronic device

A packaging structure and sub-slot technology, applied to circuits, electrical components, electrical solid devices, etc., can solve the problems of increasing the risk of board-level solder ball breakage, displacement of bare chips and heat dissipation covers, and excessive operating temperature of bare chips. Achieve the effects of reducing the risk of delamination, enhancing board-level reliability, and reducing peeling stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0038] An embodiment of the present invention provides a packaging structure, which is applied to an electronic device and fixed on a circuit board in the circuit device. In one embodiment, the encapsulation structure can be applied to electronic components with high heat generation.

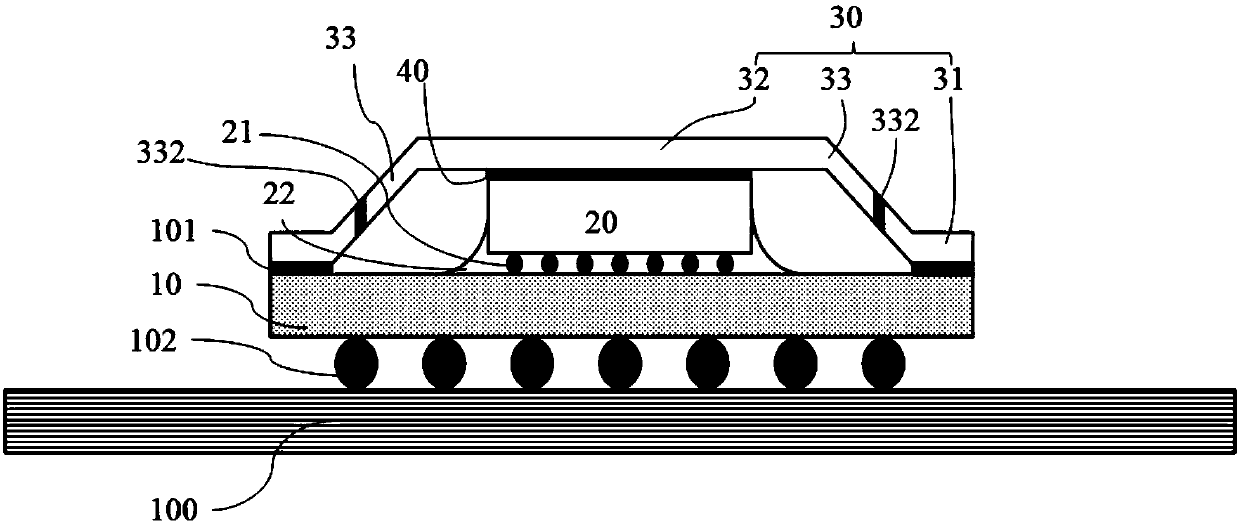

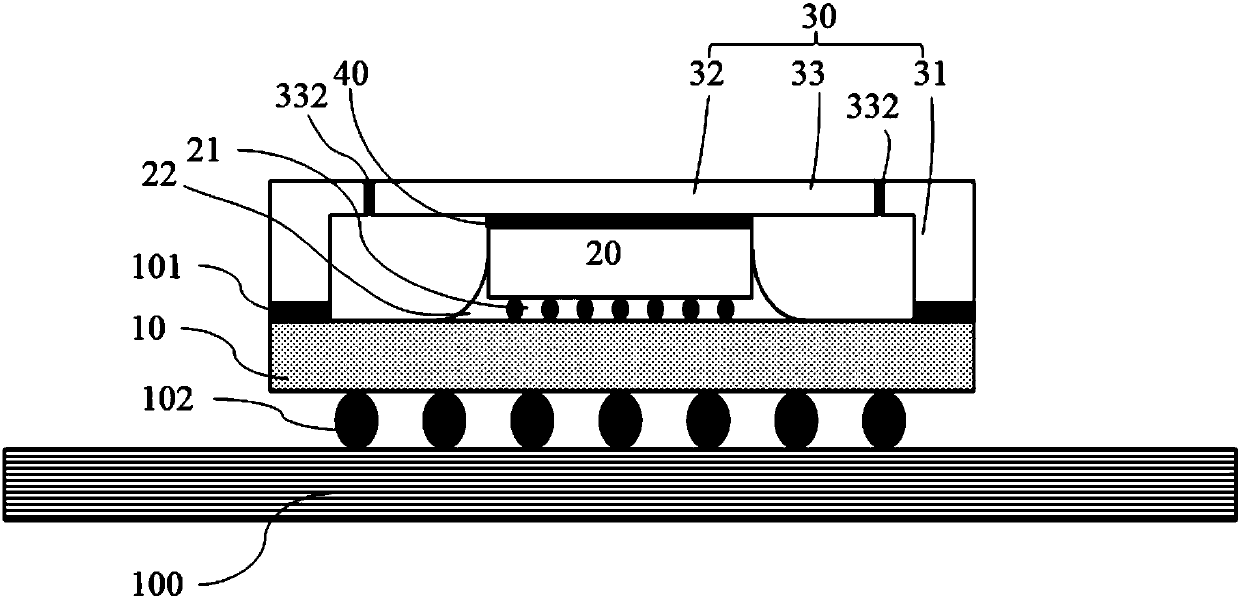

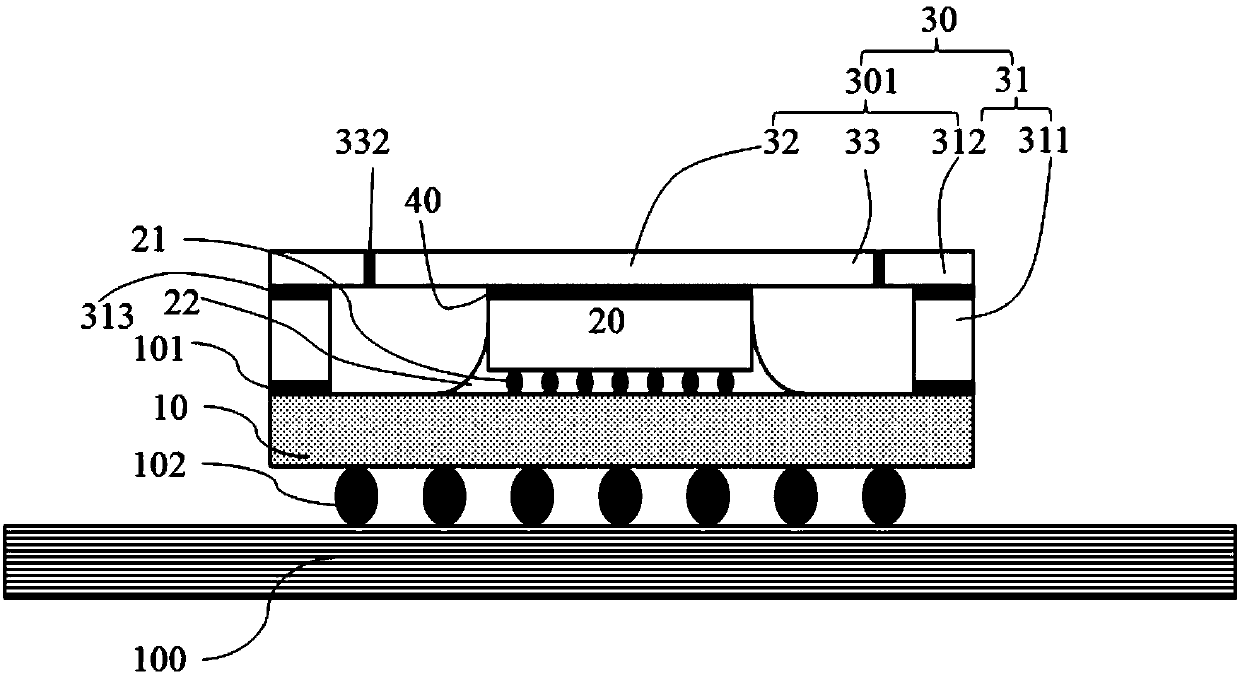

[0039] figure 1 The package structure shown includes a substrate 10, a die 20, and a heat dissipation cover 30, the die 20 is mounted on the surface of the substrate 10, the heat dissipation cover 30 is connected to the substrate 10 and covers the die the periphery of the sheet 20. The substrate 10 can be a metal substrate, a ceramic substrate or a PCB board. The upper surface of the substrate 10 is mounted with bare chips 20 and other electronic components, and the lower surface of the substrate 10 is used for electrical connection with the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com