Rework double-sided foam tape, reworking method and preparation method

A double-sided foam tape and foam technology, which is applied in the direction of bonding method, adhesive, film/sheet adhesive, etc., can solve the problem of limited operation of cutting the foam by the blade, small thickness of the foam layer, and damage to the foam. Enhance the film layer and other problems to achieve the effect of fast and convenient rework, reduce the use of adhesives, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

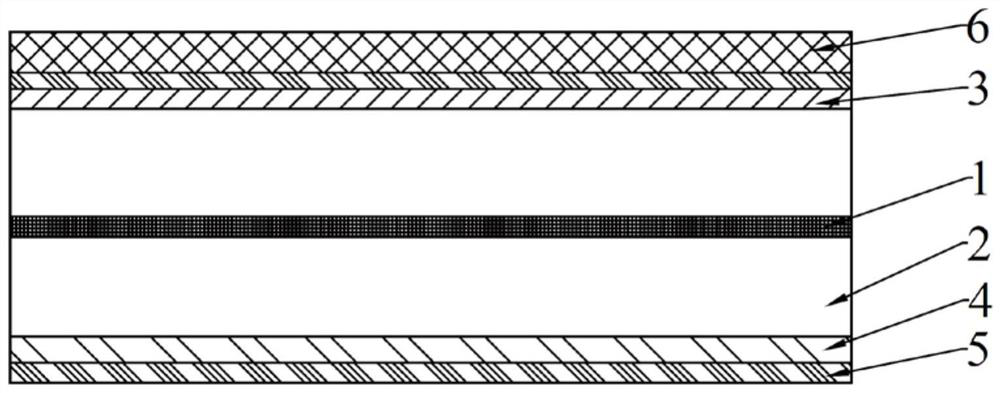

[0054] Embodiment 2 After the release layer 6 of the reworked double-sided foam tape is peeled off, the double-sided pressure-sensitive adhesive layer 5 is bonded to the workpiece respectively, and the rework method includes the following steps:

[0055] S1: Use a blade to destroy the two layers of foam layer 2 from the thickness direction section of the edge of the reworked double-sided foam tape until the elastic stretch layer 1 on the edge of the reworked double-sided foam tape is separated from the two layers of foam layer 2, as shown Figure 4 Rework double-sided foam tape shown;

[0056] S2, clamping and stretching the elastic body stretching layer 1 separated from the foam layer 2 obtained by S1 with a hand or a clamp, the stretching direction is as follows: Figure 4 As shown by the middle arrow, the stretched elastic layer 1 deforms and destroys the foam layer 2, and the stretched elastic layer 1 and the foam layer 2 separate from the stretched elastic layer 1 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com