Anticorrosive gas penetration composite packaging material and preparation method thereof

A composite packaging material and gas penetration technology, applied in the field of anti-corrosive gas penetration composite packaging materials and their preparation, can solve the problems of unstable product quality, delamination of composite materials, affecting the normal use of products, etc. The effect of beautiful patterns, improved stability, good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

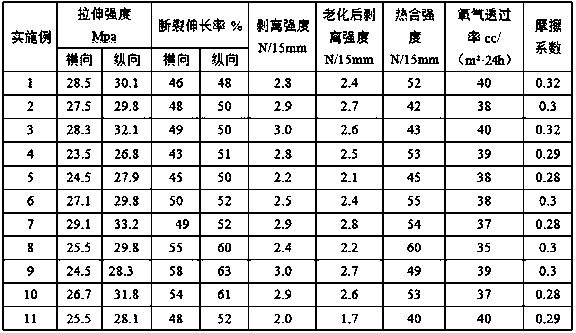

Examples

Embodiment 1

[0029] The total thickness of the corrosion-resistant gas penetration composite packaging material is 92 μm, and the thickness of the polyamide polyethylene co-extrusion film is 80 μm. The weight ratio of metallocene polyethylene and low-density polyethylene in the heat-sealing layer is 35:65; the corona layer is 100% polyamide resin; the weight ratio of the heat-sealing layer and the corona layer is 72:28.

[0030] Preparation:

[0031] (1) Add the metallocene polyethylene and low-density polyethylene for the heat-sealing layer, and the polyamide resin for the corona layer, and add them to a multi-layer extruder for co-extrusion to form a polyamide-polyethylene co-extrusion film ;The processing temperature of the resin during extrusion molding is 210°C, the production speed is 41m / min, and the inflation ratio is 2.2;

[0032] (2) The extruded polyamide polyethylene co-extruded film is cooled and shaped and cut into the required width; the cooling and shaping method is air co...

Embodiment 2

[0037] The total thickness of the corrosion-resistant gas penetration composite packaging material is 85 μm, and the thickness of the polyamide polyethylene co-extrusion film is 73 μm. The weight ratio of metallocene polyethylene and low-density polyethylene in the heat-sealing layer is 40:60; the corona layer is 100% polyamide resin; the weight ratio of the heat-sealing layer and the corona layer is 75:25.

[0038] Preparation:

[0039](1) Add the metallocene polyethylene and low-density polyethylene for the heat-sealing layer, and the polyamide resin for the corona layer, and add them to a multi-layer extruder for co-extrusion to form a polyamide-polyethylene co-extrusion film ;The processing temperature of the resin during extrusion molding is 200°C, the production speed is 42m / min, and the inflation ratio is 2.1;

[0040] (2) The extruded polyamide polyethylene co-extruded film is cooled and shaped and cut into the required width; the cooling and shaping method is air coo...

Embodiment 3

[0045] The total thickness of the corrosion-resistant gas penetration composite packaging material is 82 μm, and the thickness of the polyamide polyethylene co-extrusion film is 70 μm. The weight ratio of metallocene polyethylene and low-density polyethylene in the heat-sealing layer is 45:55; the corona layer is 100% polyamide resin; the weight ratio of the heat-sealing layer and the corona layer is 75:25.

[0046] Preparation:

[0047] (1) Add the metallocene polyethylene and low-density polyethylene for the heat-sealing layer, and the polyamide resin for the corona layer, and add them to a multi-layer extruder for co-extrusion to form a polyamide-polyethylene co-extrusion film ;The processing temperature of the resin during extrusion molding is 170°C, the production speed is 40.5m / min, and the inflation ratio is 2.3;

[0048] (2) The extruded polyamide polyethylene co-extrusion film is cooled and shaped and cut into the required width; the cooling and shaping method is air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com