Weather-resistant two-component polyurethane adhesive and solar battery back plate

A two-component polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problem of poor initial adhesion, insufficient heat resistance, poor resistance to moisture and thermal hydrolysis, etc. problems, to achieve excellent substrate adaptability, reduce the risk of delamination, and long-term effective resistance to humidity and heat environment adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

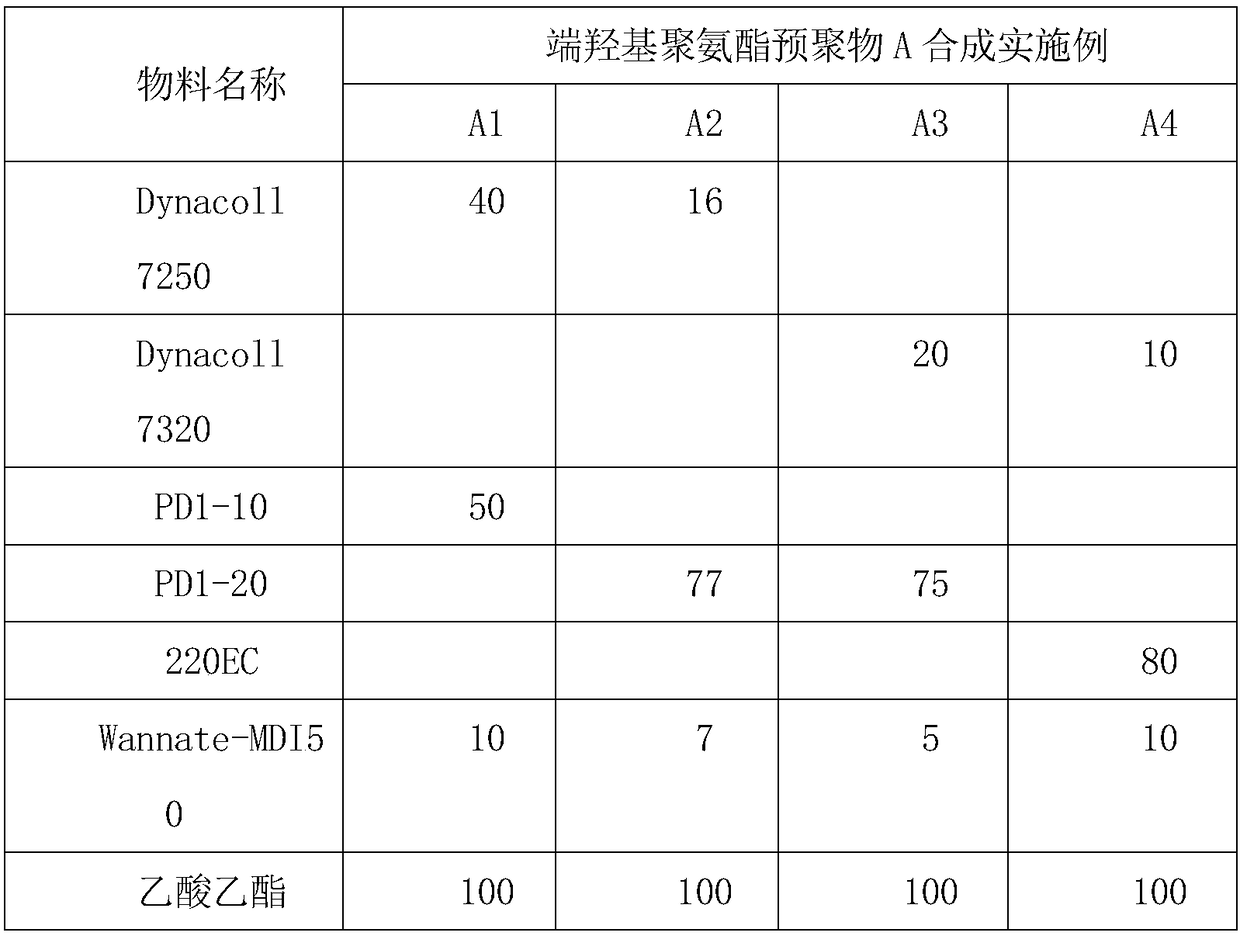

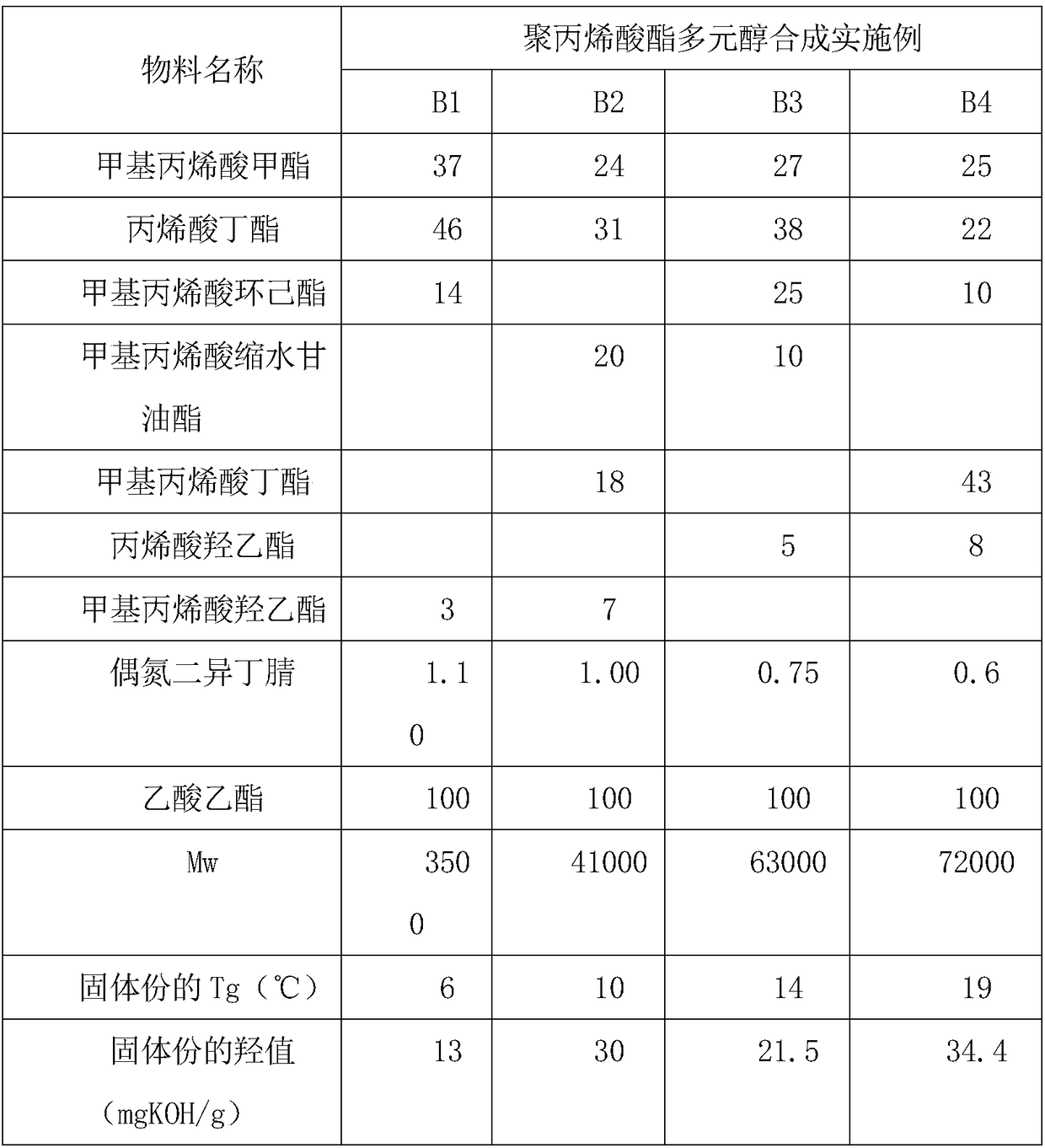

Method used

Image

Examples

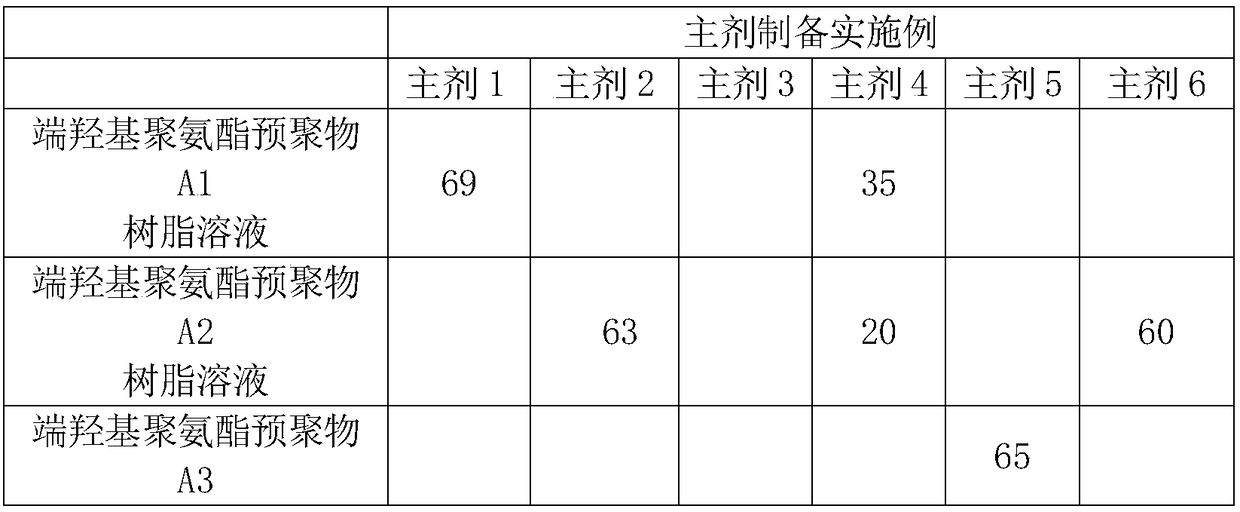

Embodiment 1-6

[0055] The adhesive formulations used in Examples 1-6 were prepared according to the parts by weight shown in Table 4, and tested using the sample performance evaluation method. Wherein, curing agent C in Table 4 is a hexamethylene diisocyanate trimer curing agent N3300 (trade name) manufactured by Bayer, with an NCO content of 21.8 wt% and a solid content of 100%.

[0056] Sample performance evaluation method:

[0057] 1. Preparation of test samples

[0058] The substrates used are polyethylene terephthalate film (PET) of 125 μm and PVDF film of 22.5 μm after corona treatment, and the prepared adhesive solution is coated on the PET film, and the glue amount is 20- 25g / m 2 , dried at 80°C for 2 minutes, fully bonded the PVDF film and the PET film to obtain a composite sample.

[0059] 2. Initial peel strength test

[0060] The peel strength test is carried out by sampling immediately after the composite sample is prepared, referring to the national standard GB / T 2790-1995 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com