Method for improving electrolytic solution resistance of binder in lithium battery negative electrode sheet by irradiation

A technology of negative pole piece and electrolyte, which is applied in the field of irradiation to improve the electrolyte resistance of the binder in the negative pole piece of lithium batteries, can solve the problems of incomplete crosslinking, non-crosslinking, limited chemical synthesis, etc., and achieve The effects of reduced processing procedures, short irradiation time, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

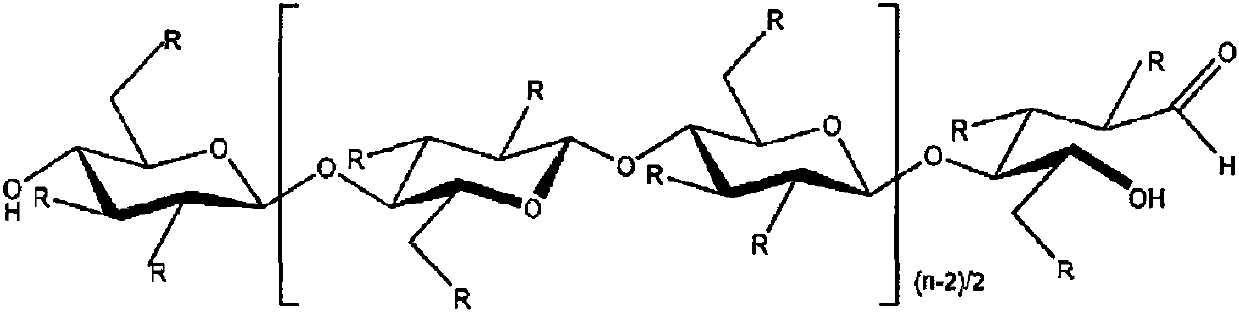

Image

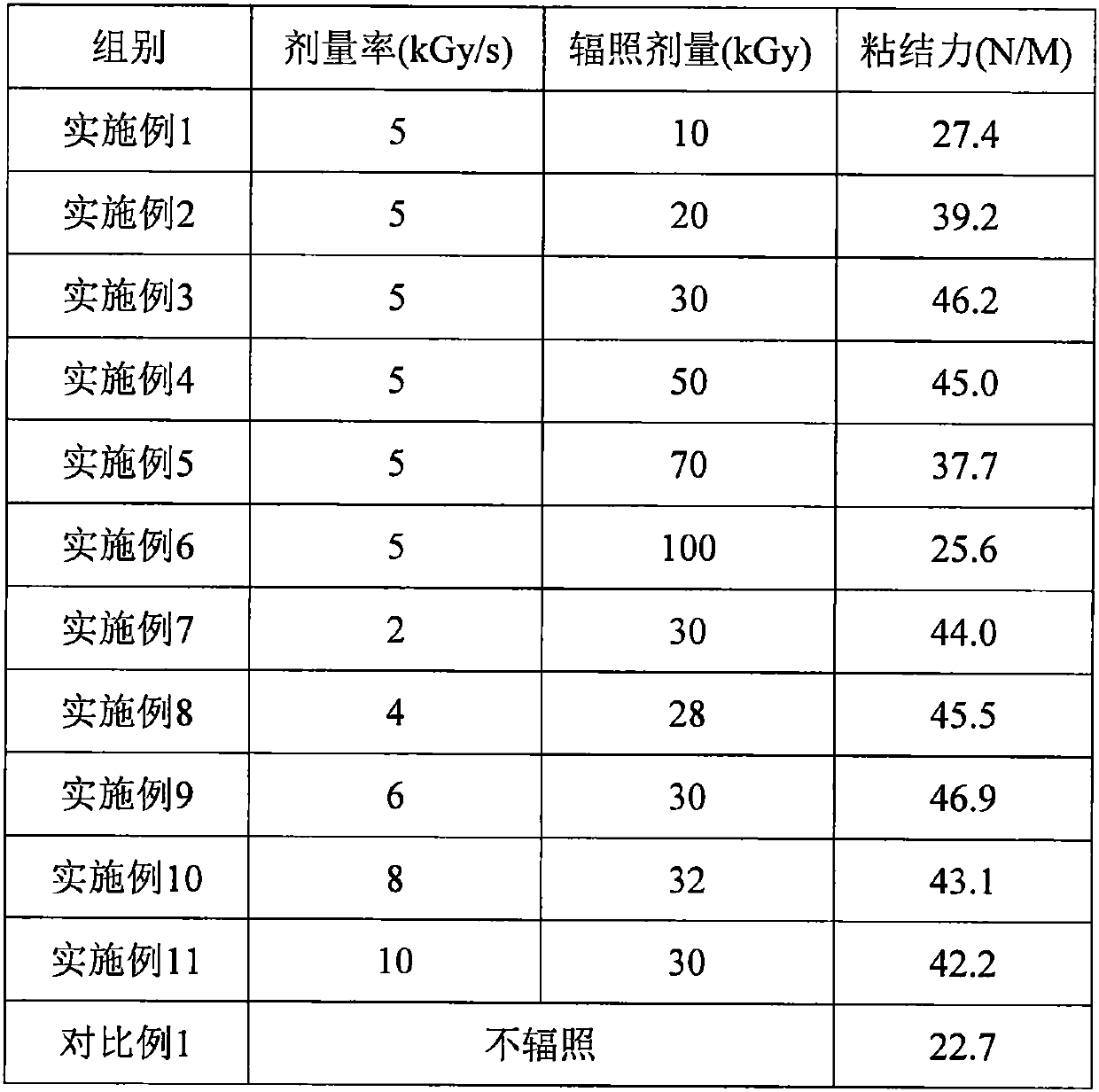

Examples

Embodiment 1

[0028] Preparation of positive electrode sheet for lithium ion battery:

[0029] Mix the positive electrode active material nickel cobalt lithium manganate, conductive carbon, and binder PVDF in the solvent NMP according to the mass ratio of 96:2:2, and stir evenly to obtain the positive electrode slurry. The positive electrode slurry obtained is coated on a 12 μm aluminum foil, dried, and cold-pressed to obtain a compacted density of 3.3 g / cm 3 The pole piece is then cut and welded to obtain the positive pole piece.

[0030] Preparation of lithium ion battery negative electrode sheet:

[0031] Add the negative electrode active materials natural graphite, conductive carbon, CMC-Na, and SBR into deionized water according to the mass ratio of 96:1:1:2, and mix well to obtain the negative electrode slurry, and then coat the negative electrode slurry on 8 μm thick The two sides of the metal copper foil are dried into a negative electrode sheet with a certain degree of flexibilit...

Embodiment 2

[0040] Different from Example 1 is the irradiation of lithium ion battery:

[0041] Lithium-ion battery dry cells are placed on the under-beam device under the irradiation accelerator, loaded on a trolley, and laid out in an orderly manner. Adjust the parameters of the irradiation equipment. By adjusting the energy of the accelerator and the speed of the device under the accelerator beam, the dose rate is 5kGy / s, and the lithium-ion battery is irradiated. The irradiation dose is 20kGy, so that CMC-Na and SBR produce alternating couplet. Then take out the lithium-ion battery dry cell from the trolley. The electrolyte is perfused through the liquid injection port, and then lithium-ion batteries are produced through processes such as formation and capacity, and the performance of the batteries is tested.

[0042] All the other are with embodiment 1.

Embodiment 3

[0044] Different from Example 1 is the irradiation of lithium ion battery:

[0045] Lithium-ion battery dry cells are placed on the under-beam device under the irradiation accelerator, loaded on a trolley, and laid out in an orderly manner. Adjust the parameters of the irradiation equipment. By adjusting the energy of the accelerator and the speed of the device under the accelerator beam, the dose rate is 5kGy / s, and the lithium-ion battery is irradiated. The irradiation dose is 30kGy, so that CMC-Na and SBR produce alternating couplet. Then take out the lithium-ion battery dry cell from the trolley. The electrolyte is perfused through the liquid injection port, and then lithium-ion batteries are produced through processes such as formation and capacity, and the performance of the batteries is tested.

[0046] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com