Reactive color paste and preparation method thereof

A reactive, colorant technology, applied in the field of ink colorants and coatings, can solve the problems of unstable colorant system, easy formation of agglomeration and sedimentation, and the appearance of pigment particles, achieving excellent storage stability, avoiding sedimentation, and improving stirring speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

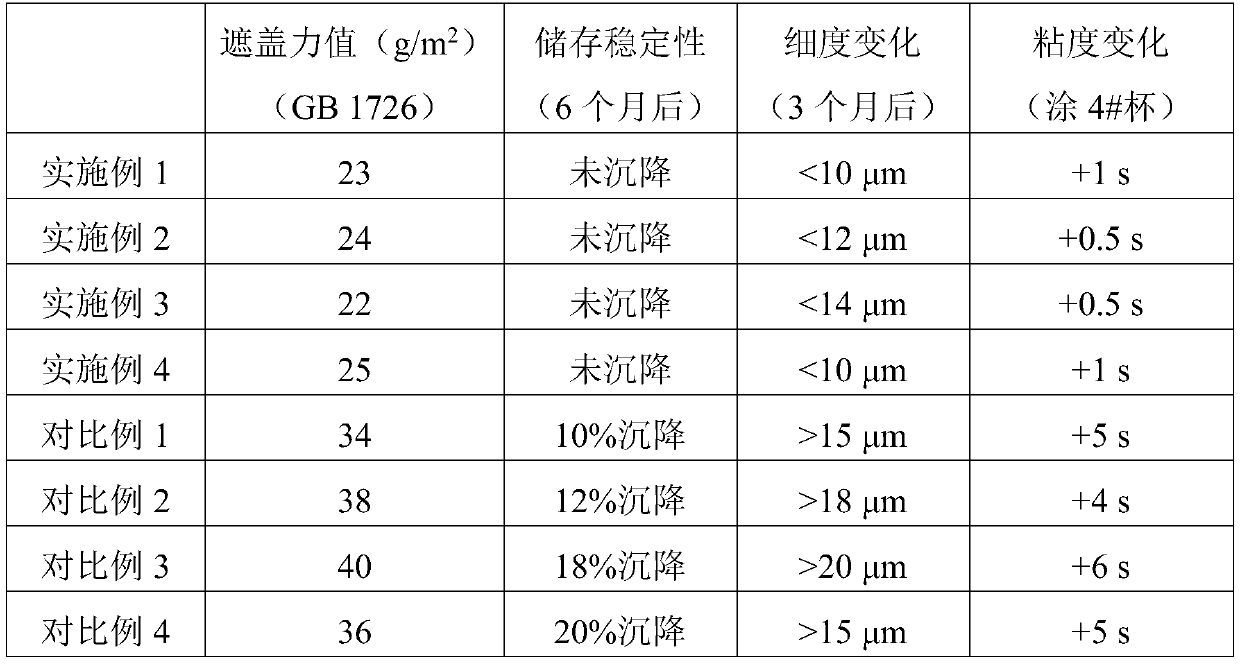

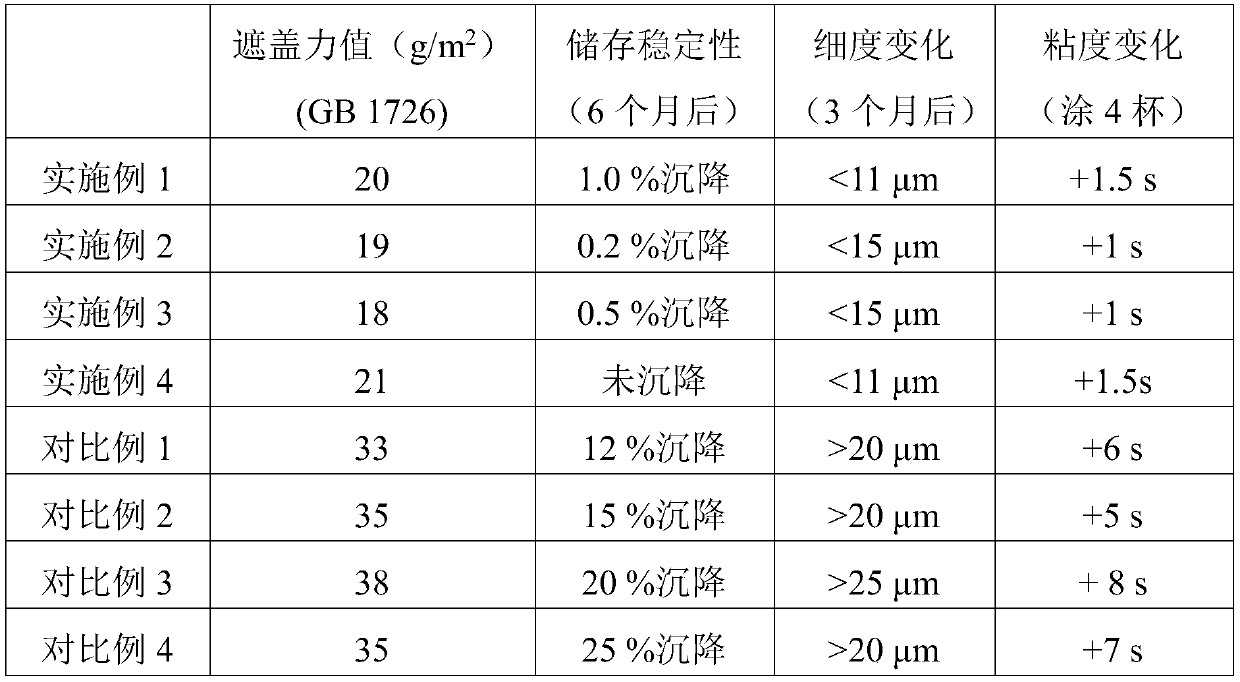

Examples

Embodiment 1

[0034] The aminated pigment in the reaction color paste is an aminated carbon nanotube, which is prepared by the following method:

[0035] (1) Surface modification of carbon nanotubes: ultrasonically disperse carbon nanotubes in solvent toluene, add initiator azobisisobutyronitrile, protect with nitrogen gas for 20 minutes, and then initiate reaction at 60°C for 90 minutes Then filter and separate, and wash with solvent toluene 3-5 times, obtain the carbon nanotube of surface modification; Wherein, the mass volume ratio of carbon nanotube, solvent and initiator is 20mg:2g:50ml, the frequency of ultrasonic is 30kHz, The time is 30 minutes; the filtration adopts polyvinylidene fluoride membrane or polytetrafluoroethylene membrane with a pore size of 0.30-0.60 μm;

[0036] (2) The surface-modified carbon nanotubes are hydrolyzed: the surface-modified carbon nanotubes are added in hydrochloric acid of 0.5mol / L, refluxed for 90min, then filtered and separated, and washed 3-5 times...

Embodiment 2

[0043] The aminated pigment in the reaction color paste is aminated carbon black, which is prepared by the following method:

[0044] (1) Surface modification of carbon black: ultrasonically disperse the carbon black in the solvent toluene, add the initiator azobisisobutyronitrile, protect with nitrogen gas for 20 minutes, and then carry out the initiation reaction at 60 ° C for 90 minutes; then Filter and separate, and wash with solvent toluene 3-5 times, obtain the carbon black of surface modification; Wherein, the mass volume ratio of carbon black, solvent and initiator is 20mg:2g:50ml, the frequency of ultrasonic is 30kHz, and the time is 30min; Filtration adopts polyvinylidene fluoride membrane or polytetrafluoroethylene membrane with a pore size of 0.30-0.60 μm;

[0045] (2) The surface-modified carbon black is hydrolyzed: the surface-modified carbon black is added in the sodium hydroxide of 0.5mol / L, refluxed for 90min, then filtered and separated, and washed 3-5 times ...

Embodiment 3

[0052] The aminated pigment in the reaction color paste is aminated carbon black, which is prepared by the following method:

[0053] (1) Surface modification of carbon black: ultrasonically disperse the carbon black in the solvent toluene, add the initiator azobisisobutyronitrile, protect with nitrogen gas for 40 minutes, and then carry out the initiation reaction at 80 ° C for 150 minutes; then Separated by filtration, and washed 3-5 times with solvent toluene to obtain surface-modified carbon black; wherein, the mass volume ratio of carbon black, solvent and initiator is 35mg:20g:50ml, the frequency of ultrasound is 90kHz, and the time is 60min; Filtration adopts polyvinylidene fluoride membrane or polytetrafluoroethylene membrane with a pore size of 0.30-0.60 μm;

[0054] (2) The surface-modified carbon black is hydrolyzed: the surface-modified carbon black is added in 2mol / L sodium hydroxide, refluxed for 150min, then filtered and separated, and washed 3-5 times with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com