Preparation method of interface-modified rice husk powder/polylactic acid biodegradable composite material

A composite material and biodegradable technology, which is applied in the field of preparation of interface-modified rice husk powder/polylactic acid biodegradable composite materials, can solve the problem of poor heat resistance and mechanical properties of polylactic acid materials, poor interface compatibility, and difficulty in forming Membrane and other issues, to achieve the effect of increasing the value of by-products, low cost, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a method for preparing an interface-modified rice husk powder / polylactic acid biodegradable composite material, which is characterized in that it comprises the following steps:

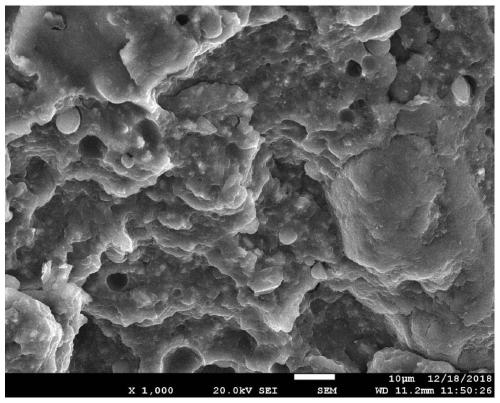

[0042] Step 1. Grinding the rice husks into 80-200 mesh powders, treating them with alkali with sodium hydroxide solution, drying them for later use;

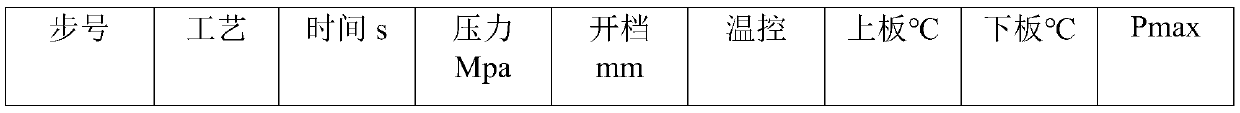

[0043] Step 2. Inject the dried rice husk powder, polylactic acid, silane coupling agent and other raw materials into the twin-screw extruder at a ratio of 60:40:4-6 by weight fraction, and obtain interface modification by screw extrusion. Rice husk powder / polylactic acid biodegradable composites.

[0044] In a preferred version, in the step 1, the specific method of rice husk powder processing is:

[0045] Wash the rice husk with water for 1-2 times to remove solid impurities and dust. After air-drying, use a universal grinder to grind it to 80-200 mesh.

[0046] In a preferred version, in the step 1, the specific method ...

Embodiment 1

[0066] Step 1. Grinding the rice husks into 80-200 mesh powders, treating them with alkali with sodium hydroxide solution, drying them for later use;

[0067] Step 2. Inject the dried rice husk powder, polylactic acid, silane coupling agent and other raw materials into the twin-screw extruder in a ratio of 60:40:4 by weight fraction, and extrude the interface-modified rice husk Powder / PLA biodegradable composite.

Embodiment 2

[0069] Step 1. Grinding the rice husks into 80-200 mesh powders, treating them with alkali with sodium hydroxide solution, drying them for later use;

[0070] Step 2. Inject the dried rice husk powder, polylactic acid, silane coupling agent and other raw materials into the twin-screw extruder at a ratio of 60:40:4.5 by weight fraction, and extrude through the screw to obtain interface-modified rice husk Powder / PLA biodegradable composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com