Method for preparing cross-linked polymer film by branching molecule

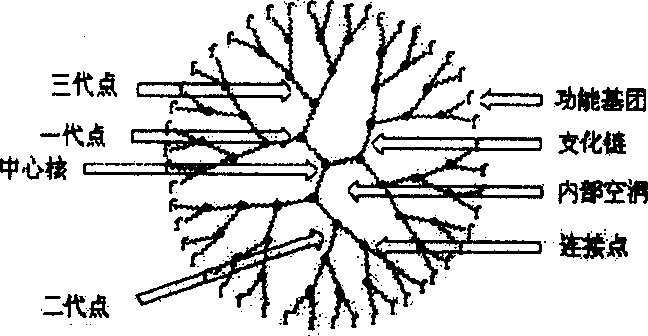

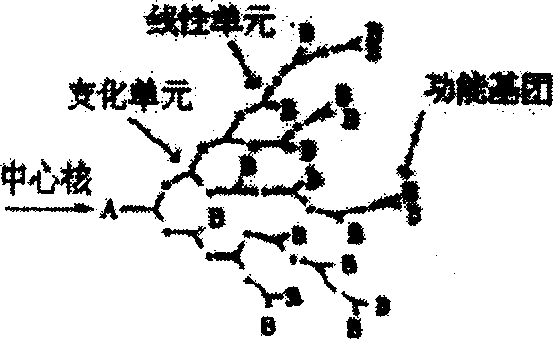

A dendritic and molecular technology, applied in the field of polymer membrane preparation, to achieve the effects of easy processing into membranes, improved anti-adsorption, and improved water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Raw material preparation

[0048] (1) Preparation of dendrimers whose ends are amino groups: dendrimers whose ends are amino groups are synthesized by a step-by-step method by alternating reactions of Micheal addition and aminolysis from ethylenediamine and methyl acrylate. Add 200ml of methanol and 200ml of ethylenediamine into a 500ml reaction vessel, stir at room temperature, deoxygenate for half an hour, start adding 125ml of methyl acrylate to the above mixture dropwise, and stop the reaction after 24 hours of reaction. The excess methyl acrylate and methanol were distilled off under reduced pressure to obtain the 0.5 generation dendrimer. Weigh 16.32g of the half-generation dendrimers obtained above and add them to the reaction vessel, add 200ml of methanol and 550ml of ethylenediamine and stir for 4 days in a water bath, then distill most of the ethylenediamine out under reduced pressure, leaving a small amount of ethylenediamine After diamine is added to toluen...

Embodiment 1

[0054] Embodiment 1: the preparation of poly(amine-ester) hyperbranched polymer crosslinked membrane

[0055] The fifth-generation hyperbranched poly(amine-ester) 14.69g synthesized by the above-mentioned quasi-one-step method is mixed with 35.2ml concentration of 25wt% glutaraldehyde aqueous solution to obtain a light yellow transparent solution, which is then placed in a water bath at 60°C Heated to pre-crosslink the hyperbranched polymer, and the solution changed from light yellow to yellow after 8 hours of reaction, and the transparency decreased. Cast the pre-crosslinked casting solution onto a clean glass or stainless steel support carrier, scrape the casting solution into a liquid film with a uniform thickness with a scraper with a blade depth of 150 μm, and then place the glass or stainless steel with the liquid film The carrier was placed in a vacuum oven and kept at 130° C. for 6 hours to form a nascent film. Then transfer the carrier forming the nascent film to an ...

Embodiment 2

[0058] Embodiment 2: the preparation of poly(amine-ester) hyperbranched polymer crosslinked membrane

[0059] The sixth generation hyperbranched poly(amine-ester) 14g synthesized by the above-mentioned quasi-one-step method is mixed and stirred with 16.36ml concentration of 25wt% glutaraldehyde solution to obtain a uniform light yellow transparent solution, which is then placed in a water bath at 90°C The hyperbranched polymer was pre-crosslinked by heating in medium, and the solution changed from light yellow to yellow after 4 hours of reaction, and the transparency decreased. Cast the pre-crosslinked casting solution onto a clean glass or stainless steel support carrier, scrape the casting solution into a liquid film with a uniform thickness with a scraper with a blade depth of 150 μm, and then place the glass or stainless steel with the liquid film The carrier was placed in a vacuum oven and kept at 120° C. for 10 h to form a nascent film. Then transfer the carrier forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com