Fluorenyl anion-exchange membrane containing comb-shaped side chains and preparation method of fluorenyl anion-exchange membrane

A technology of ion exchange membrane and fluorenyl anion, which is applied in the field of anion exchange membrane and its synthesis, can solve the complex synthesis of polycation quaternization reagents and other problems, and achieve real and controllable membrane structure and performance, low conductivity, and enhanced water retention Ability and effect of anti-swelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

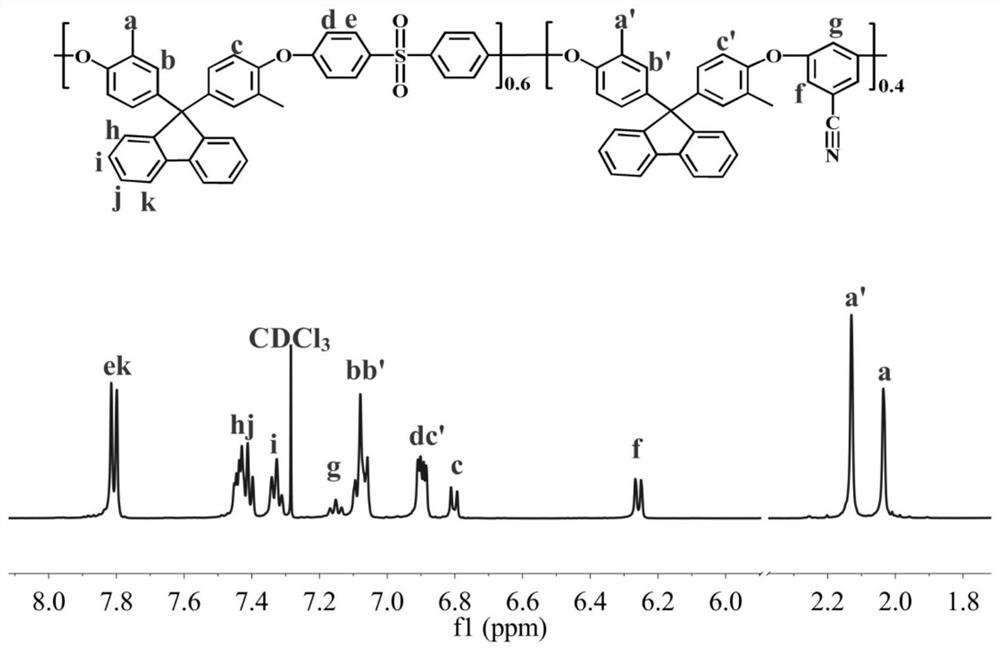

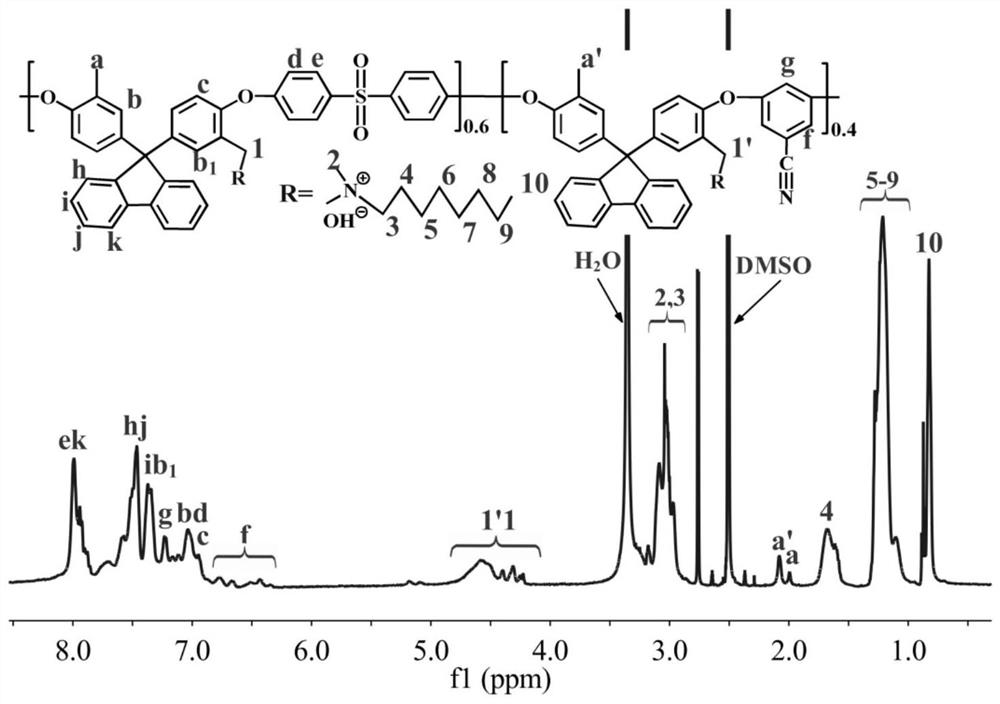

[0046]In this embodiment, the comb-shaped fluorenyl polyaryl ether sulfone nitrile anion exchange membrane containing 8 carbon atoms and long carbon chains (the proportion of sulfone segments is 60%) is taken as an example, and the structural formula is as follows:

[0047]

[0048] where R is H or Concrete preparation method comprises the following steps:

[0049] 1) Synthesis of fluorenyl polymer: 1.723g 4,4'-dichlorodiphenylsulfone (6mmol), 0.688g 3,5-dichlorobenzonitrile (4mmol), 3.785g 9,9-bis(3-methyl Dimethyl-4-hydroxyphenyl) fluorene (10mmol), 3.455g (25mmol) anhydrous potassium carbonate and 10mL toluene were dissolved in 25mL N,N-dimethylacetamide, under nitrogen protection, reacted at 145°C for 4h, then raised the temperature Reaction at 165°C for 20h, after cooling, precipitate with 500mL methanol aqueous solution (the volume ratio of methanol to water is 1:1), filter, wash and dry to obtain the fluorenyl polymer.

[0050] 2) Synthesis of bromomethylated poly...

Embodiment 2

[0055] In this embodiment, the comb-shaped fluorenyl polyarylether ketone nitrile anion exchange membrane containing 8 carbon atoms and long carbon chains (the ratio of the ketone segment is 20%) is taken as an example, and the structural formula is as follows:

[0056]

[0057] where R is H or Concrete preparation method comprises the following steps:

[0058] 1) Synthesis of fluorenyl polyarylether ketone nitrile polymer: 0.504g 4,4'-dichlorobenzophenone (2mmol), 1.376g 3,5-dichlorobenzonitrile (8mmol), 3.785g 9,9- Bis(3-methyl-4-hydroxyphenyl)fluorene (10mmol), 3.732g (27mmol) anhydrous potassium carbonate, 25mL polar aprotic solvent N,N-dimethylformamide, nitrogen protection, prior to 145 ℃ for 4 hours, and then heated to 165 ℃ for 20 hours, after cooling, precipitated with 500mL methanol aqueous solution (the volume ratio of methanol to water was 1:1), filtered, washed and dried to obtain polyaryletherketonenitrile polymer.

[0059] 2) Synthesis of bromomethylated p...

Embodiment 3

[0063] In this embodiment, the anion-exchange membrane of fluorenyl polyarylether ketone nitrile containing 10 carbon atoms and long carbon chain comb-shaped fluorenyl polyarylether ketone nitrile (the proportion of ketone segment is 40%) is taken as an example, and the structural formula is as follows:

[0064]

[0065] where R is H or Concrete preparation method comprises the following steps:

[0066] 1) Synthesis of polyaryl ether ketone nitrile polymer: 1.002g 4,4'-dichlorobenzophenone (4mmol), 1.032g 3,5-dichlorobenzonitrile (6mmol), 3.785g 9,9-di (3-Methyl-4-hydroxyphenyl)fluorene (10mmol), 3.814g (27.6mmol) anhydrous potassium carbonate and 10mL toluene were dissolved in 25mL N,N-dimethylacetamide, nitrogen protection, first at 145°C React for 4 hours, then raise the temperature to 170°C and react for 20 hours. After cooling, precipitate with 500 mL methanol aqueous solution (the volume ratio of methanol to water is 1:1), filter, wash, and dry to obtain polyaryleth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com