Anion exchange membrane containing dense flexible ion strings and preparation method of anion exchange membrane

An anion exchange membrane, ion technology, applied in the field of membrane science, can solve the problems of weakened dimensional stability, decreased mechanical strength, failure, etc., to achieve good chemical stability and thermal stability, improved membrane conductivity, increased density and The effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

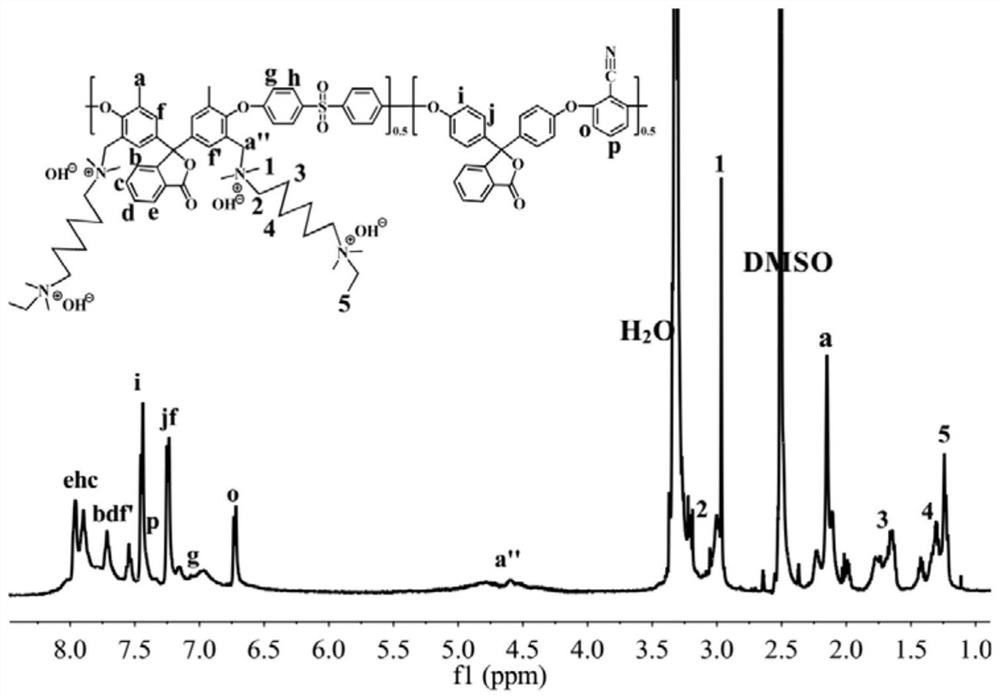

[0046] In this example, 6-(dimethylamino)-N-ethyl-N,N-dimethylhexane-1-ammonium bromide was used as the quaternization reagent to synthesize polyaryl ether sulfone type containing dense flexible ion strings The anion exchange membrane has the following structural formula:

[0047]

[0048] where R is H or

[0049] Concrete preparation method comprises the following steps:

[0050] 1) Synthesis of polyarylethersulfone polymer: 7.489g (20mmol) of 3,3-bis(4-hydroxy-3,5-dimethylphenyl)phthalide (CAS No.: 3689-45-0, C 24 h 22 o 4 , molecular weight 374.43), 5.085g (20mmol) of 4,4'-difluorodiphenyl sulfone, 4.789g (35mmol) of anhydrous potassium carbonate and 10mL of toluene dissolved in N,N-dimethylacetamide, nitrogen protection, First react at 145°C for 4.5h, then raise the temperature to 170°C for 11h, and then cool the reaction solution to room temperature. Add 2.782g (20mmol) of 2,6-difluorobenzonitrile and 6.367g (20mmol) of phenolphthalein to the above reaction sol...

Embodiment 2

[0056] In this example, 6-(dimethylamino)-N,N,N-trimethylhexane-1-ammonium bromide was used as a quaternization reagent to synthesize a polyaryletherketone anion exchange membrane containing flexible ion strings. For example, the structural formula is as follows:

[0057]

[0058] where R is H or

[0059] Concrete preparation method comprises the following steps:

[0060] 1) Synthesis of polyaryletherketone polymer: 4.364g (20mmol) of 4,4'-difluorobenzophenone, 7.489g (20mmol) of 3,3-bis(4-hydroxyl-3,5- Dimethylphenyl)phthalide, 4.789g (35mmol) of anhydrous potassium carbonate and 12mL of toluene were dissolved in N,N-dimethylacetamide, under nitrogen protection, reacted at 145°C for 4.5h, and then heated to 170°C After reacting for 11 h, the reaction solution was cooled to room temperature. Then add 4.364g (20mmol) of 4,4'-difluorobenzophenone and 6.367g (20mmol) of phenolphthalein to the above reaction solution, raise the temperature to 145°C for 4.5h, then raise the...

Embodiment 3

[0065] This embodiment takes the synthesis of polyarylether sulfone ketone anion exchange membrane containing three cation flexible ion strings with 12 carbon atoms as an example. The structural formula is as follows:

[0066]

[0067] where R is H or Br or

[0068] Concrete preparation method comprises the following steps:

[0069] 1) Synthesis of polyaryl ether sulfone ketone polymer: 5.085g (20mmol) of 4,4'-difluorodiphenyl sulfone, 7.489g (20mmol) of 3,3-bis(4-hydroxyl-3,5- Dimethylphenyl)phthalide, 4.789g (35mmol) of anhydrous potassium carbonate and 10mL of toluene were dissolved in N,N-dimethylacetamide, under nitrogen protection, reacted at 145°C for 4.5h, and then heated to 170°C After reacting for 12 h, the reaction solution was cooled to room temperature. Then add 4.364g (20mmol) of 4,4'-difluorobenzophenone and 6.367g (20mmol) of phenolphthalein to the above reaction solution, raise the temperature to 145°C for 4.5h, then raise the temperature to 180°C for 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

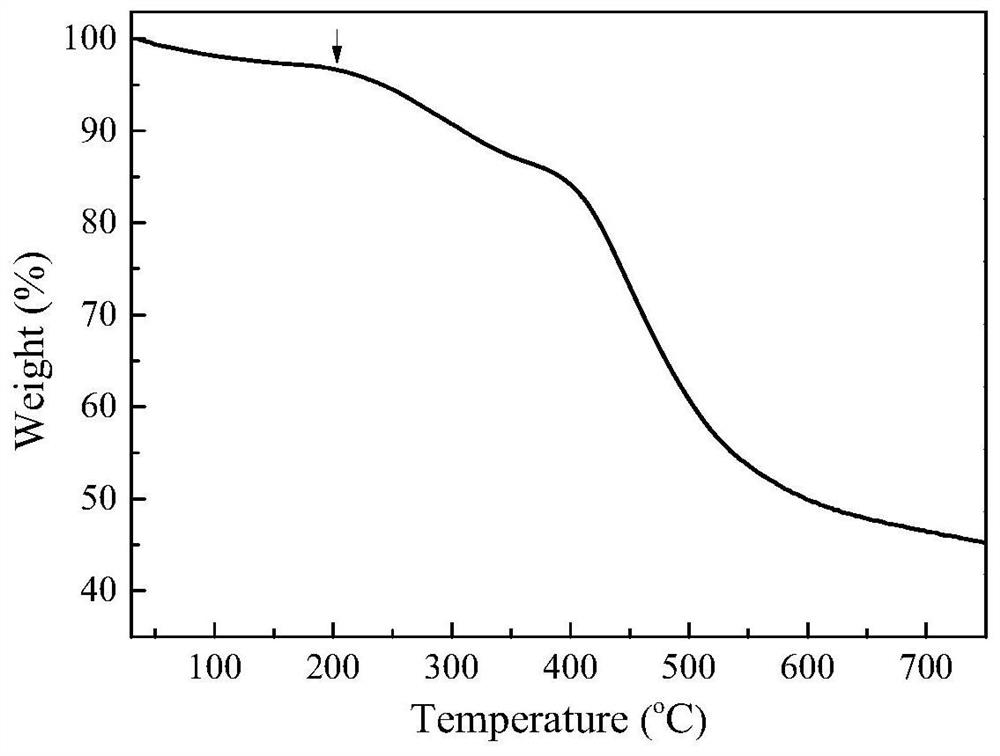

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com