Magnolol synthesizing method

A synthesis method and a technique for honokiol, applied in the field of honokiol synthesis, can solve the problems of harsh synthesis conditions, low yield of honokiol, no industrial practicability, etc., and achieve high yield, low cost, and synthesis process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

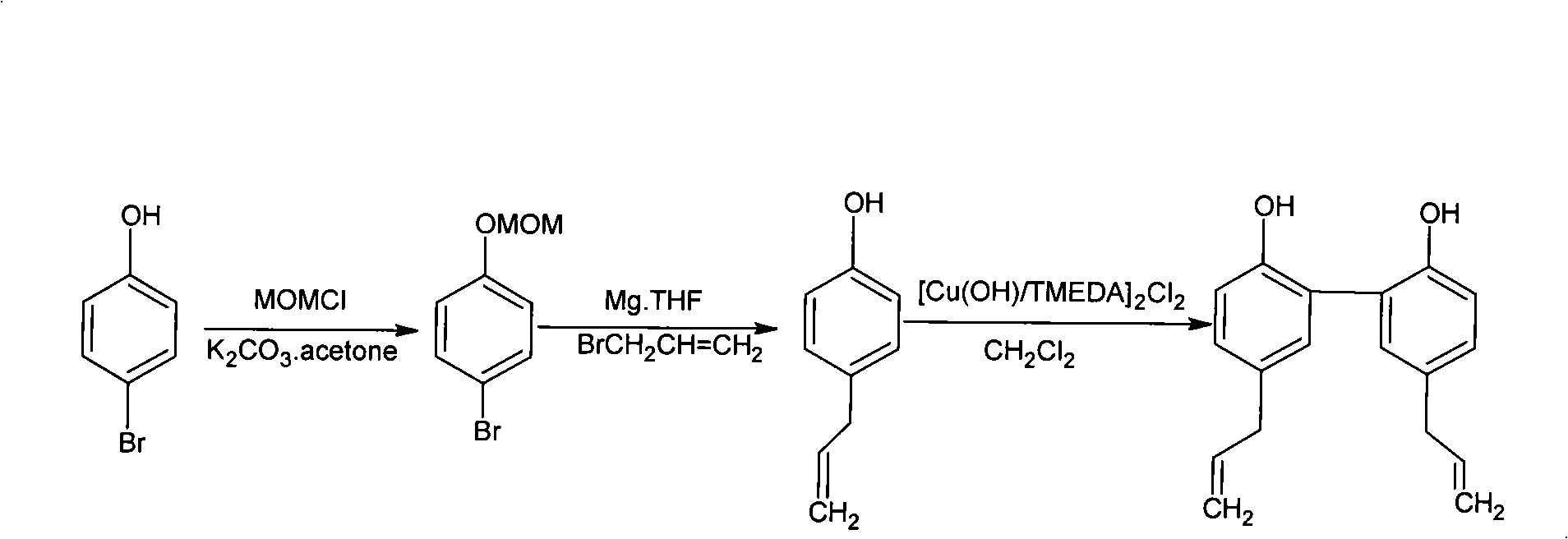

[0022] (one), figure 1 It is the synthesis route diagram of the embodiment of the present invention, such as figure 1 As shown, the whole synthesis is divided into three steps:

[0023] The first step is to prepare p-bromobenzyl methyl ether: p-bromophenol is dissolved in an acetone solvent, potassium carbonate and chloromethyl methyl ether (MOMCl) are added, and p-bromobenzyl methyl ether is obtained through reflux reaction;

[0024] The effect of the above reaction is to protect the hydroxyl group of p-bromophenol first, so that the hydroxyl group is not affected by the Grignard reaction described below. The expression of its reaction is as follows:

[0025]

[0026] The second step is to prepare p-allyl phenol: the p-bromobenzyl methyl ether prepared in the first step is reacted with allyl bromide under the participation of tetrahydrofuran solvent and magnesium chips to obtain p-allyl phenol Propylphenol; the expression of its reaction is as follows:

[0027]

[0...

Embodiment 1

[0037] Embodiment 1: the embodiment that the present invention synthesizes three steps, press figure 1 The synthetic route shown.

[0038] First prepare intermediate product p-allyl phenol, comprise following two steps:

[0039] Step A, prepare p-bromobenzyl methyl ether: put 25g (0.1445mol) p-bromophenol in a flask, add 200 ml of acetone, dissolve p-bromophenol in acetone, then add 17.5g (0.127mol) potassium carbonate After stirring for 15 minutes, 15 g (0.185 mol) of chloromethyl methyl ether was evenly added dropwise within about 10 minutes, and refluxed for 3 hours. After the solvent was evaporated, water was added to dissolve it, and the organic phase was extracted three times with ether, and the pH was adjusted by adding sodium hydroxide solution. value to 13-14, wash the organic phase with water until neutral, dry with anhydrous sodium sulfate, filter, and concentrate the filtrate to obtain 28.2 g of a colorless oil, with a yield of 90%.

[0040] Step B, preparing p-a...

Embodiment i

[0042] Under the protection of nitrogen, add 5ml of anhydrous tetrahydrofuran to cover 0.24g (10mmol) of magnesium chips, add dropwise 2 drops of p-bromobenzyl methyl ether obtained in step A, add 1 grain of iodine, and stir for 5-10 minutes. See that the color fades, add 1.8g (8.29mmol) p-bromobenzyl methyl ether solution diluted with 10ml tetrahydrofuran dropwise evenly within 10 minutes, add 2ml tetrahydrofuran, keep stirring at 50°C for 1 hour, the prepared format Add the reagent dropwise into a flask containing 1.5g (12.4mmol) allyl bromide, reflux for 4 hours, stop the reaction, cool to room temperature, add dropwise 40ml of 3mol / L hydrochloric acid solution for acid hydrolysis for 2 hours, stop the reaction and separate The tetrahydrofuran phase, the organic phase was extracted 3 times with ether, and then the organic phase was washed with sodium chloride solution to neutrality, dried with anhydrous sodium sulfate, filtered, and the filtrate was concentrated under normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com