Recycling system of chlorination mother solution and recycling method thereof

A technology of mother chlorination and chlorination liquid, which is applied in the field of recycling system of chlorination mother liquid, can solve problems such as increased production costs, environmental pollution, and large amounts of waste liquid, and achieves reduction of environmental protection costs, improvement of economic benefits, and reduction of production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

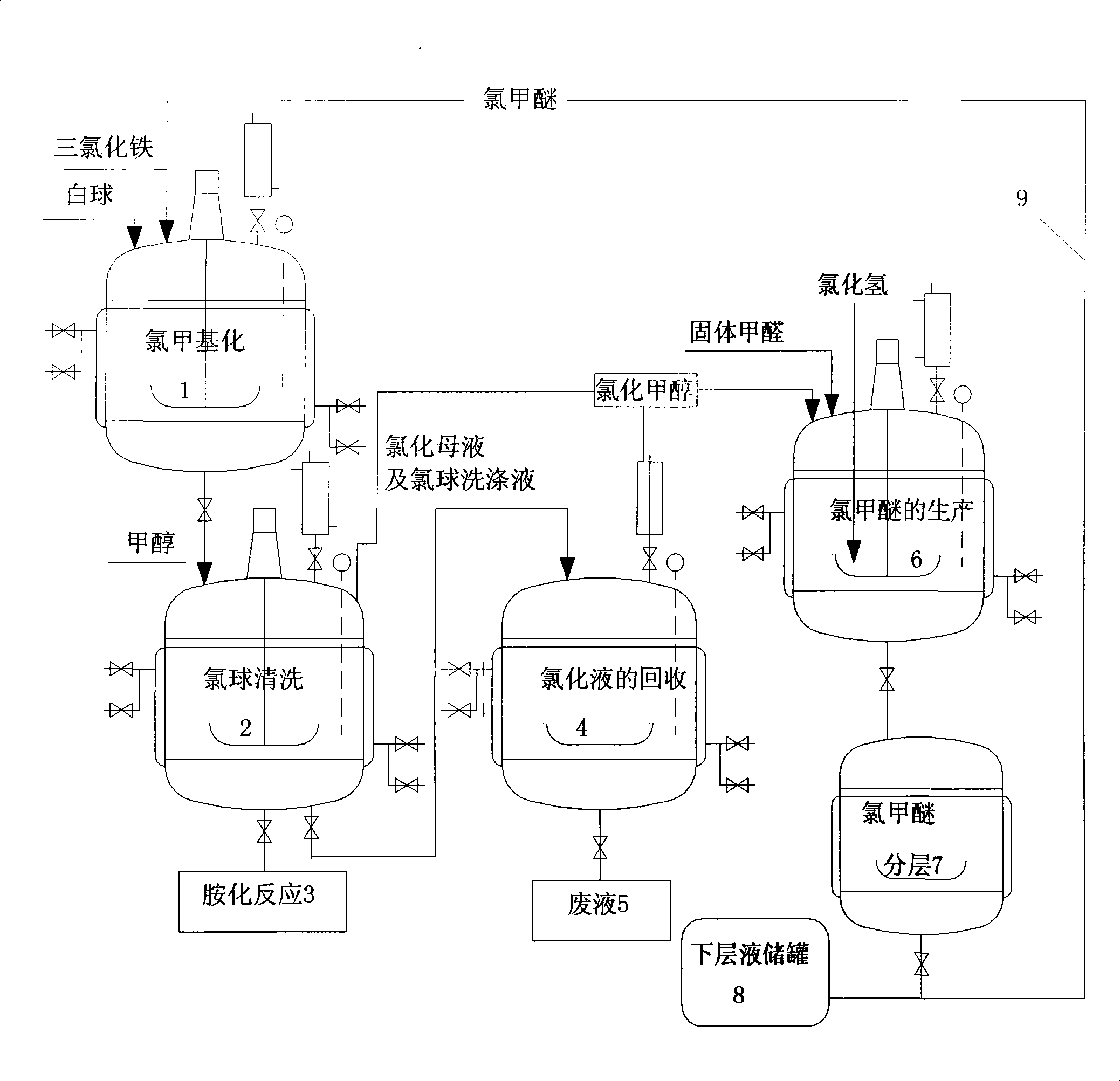

[0028] Embodiment 1: with reference to attached figure 1 . The recycling system of the chlorination mother liquor, the processing and manufacturing of the chloromethylation reactor 1 are prior art, and are not described here. The inlet of chloromethylation reaction kettle 1 is respectively connected with the outlet of the air flow conveying system and pump delivery, the outlet of chloromethylation reaction kettle 1 is connected with the inlet of chlorine ball washing reaction kettle 2 through pipes and valves, and the chlorine ball washing reaction kettle The processing and manufacturing of 2 is a prior art, and is not described here. The chlorine ball that the chlorine ball washing reactor 2 produces enters the amination reaction system 3 through the pipeline and the valve that are connected with its outlet, and the processing and manufacturing of the chlorine ball washing reactor 2 is a prior art, and will not be described here. The chlorinated mother liquor and the chlori...

Embodiment 2

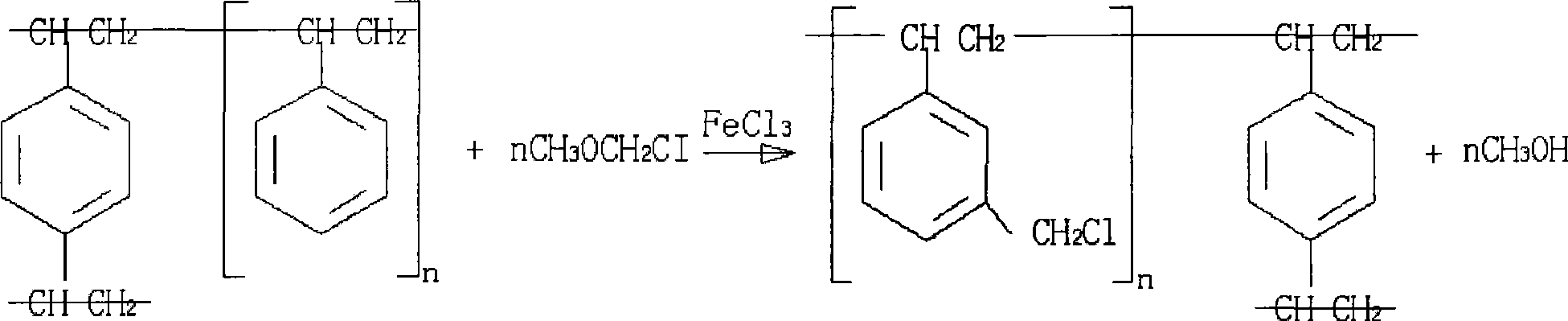

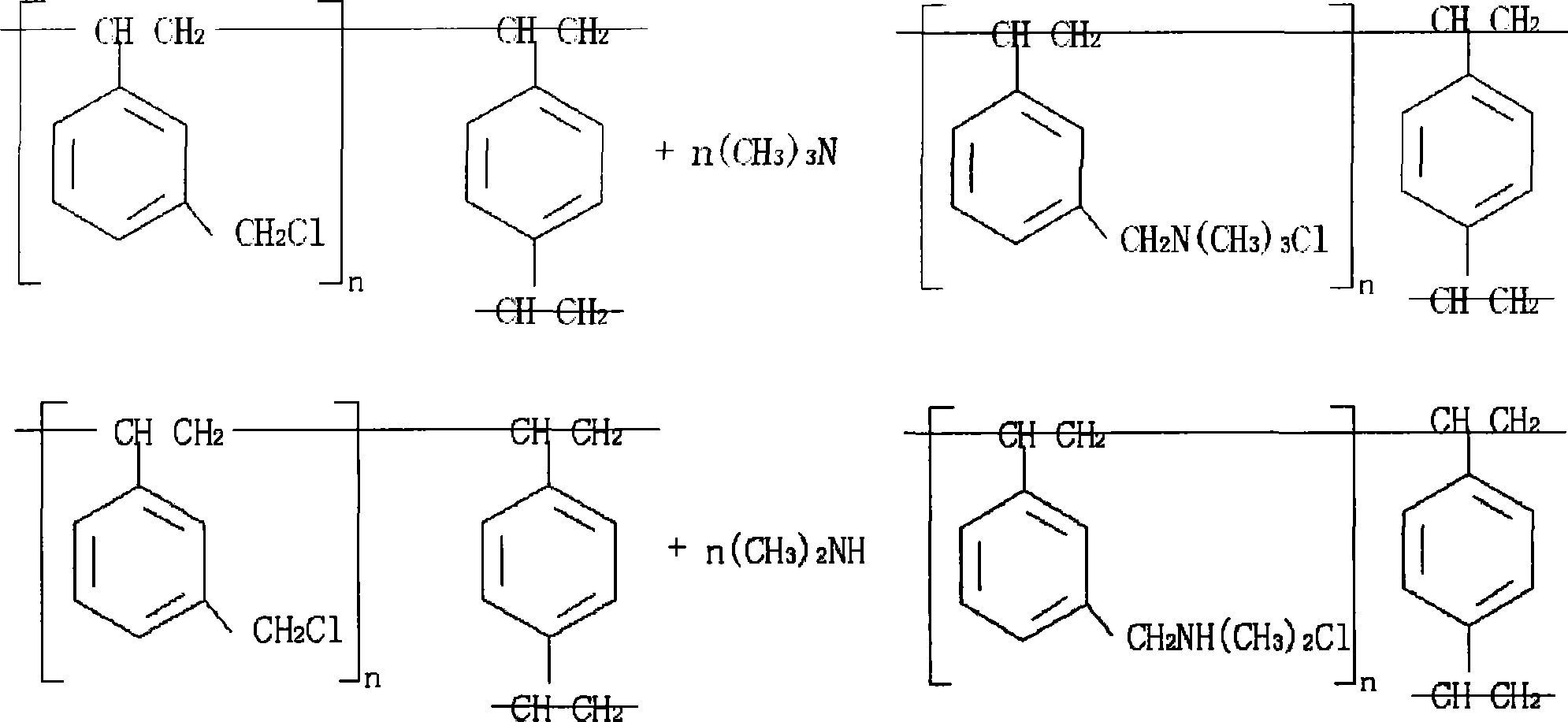

[0029] Embodiment 2: on the basis of embodiment 1, with reference to appended figure 1 ~3. The recycling method of chlorinated mother liquor, the white ball and chloromethyl ether are transported to the chloromethylation reaction kettle through the air flow conveying system and the pump respectively, stirred at normal temperature, after expansion, adding ferric chloride dissolved in chloromethyl ether to catalyze , produce an exothermic reaction, adjust the adding speed of chloromethyl ether according to the temperature, the temperature is in the range of 20°C to 48°C, and the adding speed of chloromethyl ether and white ball is controlled within 2 tons / hour. After the temperature is raised to 40-55°C and kept warm for 8-12 hours, chlorine spheres are prepared, and the temperature is lowered. The separated chlorine spheres are placed in the washing tank, and the chlorine spheres are washed with chlorinated methanol for 1-3 times in sequence, and the chlorine spheres are washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com