Method for preparing polyphenylene sulfide-based strong basic ion exchange fibers

A polyphenylene sulfide fiber and polyphenylene sulfide-based technology is applied in the field of preparation of polyphenylene sulfide-based strong base ion-exchange fibers, and achieves the effects of simplified preparation method, easy popularization and application, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

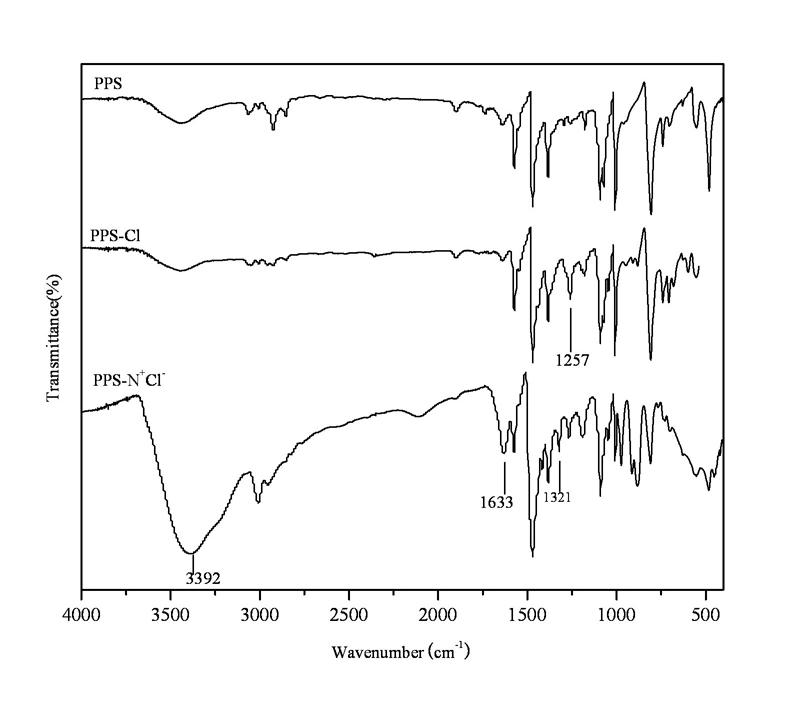

Image

Examples

Embodiment 1

[0034] The preparation method of polyphenylene sulfide base strong base ion exchange fiber of the present invention, its detailed steps are as follows:

[0035] a. Chloromethylation and cross-linking reaction: Weigh 4.1047g of basic raw material polyphenylene sulfide fiber, 50ml of solvent dichloroethane and place it in a 100ml three-necked flask for swelling for 12 hours. After swelling, recover 25ml of dichloroethane, and then add Weigh 20ml of the basic raw material chloromethyl ether and 3ml of the catalyst anhydrous tin tetrachloride, shake and shake well, heat the reaction solution to 55°C in an oil bath after shaking well, and react at this temperature for 20h; after the reaction, chloromethylated Cross-link polyphenylene sulfide fibers, cool the obtained fibers to room temperature, wash them with distilled water and absolute ethanol in turn, then extract them with absolute ethanol in a Soxhlet extractor for 8 hours, wash with distilled water after extraction, and remove...

Embodiment 2

[0038] The preparation method of polyphenylene sulfide base strong base ion exchange fiber of the present invention, its detailed steps are as follows:

[0039] a. Chloromethylation and crosslinking reaction: Weigh 5.4819g of basic raw material polyphenylene sulfide fiber, 50ml of solvent dichloroethane and place it in a 100ml three-necked flask for swelling for 13 hours. After swelling, recover 20ml of dichloroethane, and then add Weigh 30ml of the basic raw material chloromethyl ether and 4ml of the catalyst anhydrous tin tetrachloride, shake and shake well, heat the reaction solution with an oil bath to 50°C for 25h; Phenylsulfide fiber, the obtained fiber is cooled to room temperature, washed with distilled water and absolute ethanol in turn, then extracted with absolute ethanol in a Soxhlet extractor for 10 hours, washed with distilled water after extraction, and chloromethyl The ethanol in the cross-linked polyphenylene sulfide fiber is desiccated, and the washed fiber i...

Embodiment 3

[0042] The preparation method of polyphenylene sulfide base strong base ion exchange fiber of the present invention, its detailed steps are as follows:

[0043] a. Chloromethylation and crosslinking reaction: Weigh 13.6311g of basic raw material polyphenylene sulfide fiber, 80ml of solvent dichloroethane, and 80ml of chloromethyl ether in a 250ml three-necked flask for swelling for 14 hours, and add catalyst anhydrous after swelling Shake 8ml of tin tetrachloride and shake well, heat the reaction solution with an oil bath to react at 55°C for 30h; after the reaction is completed, chloromethylated cross-linked polyphenylene sulfide fibers are obtained, and the obtained fibers are cooled to room temperature, followed by Wash with distilled water and absolute ethanol, then extract it with absolute ethanol in a Soxhlet extractor for 12 hours, wash with distilled water after extraction, remove the ethanol in the chloromethylated cross-linked polyphenylene sulfide fiber, and The was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com