Polymer anion exchange membrane based on imidazole onium salt and preparation method thereof

An anion-exchange membrane and imidazolium salt technology, applied in the field of polymer anion-exchange membranes based on imidazolium salts and its preparation, can solve the problems of toxicity, poor chemical stability and thermal stability, and difficulty in chloromethylation position and reaction degree Precise control and other issues to achieve excellent mechanical properties, prevent membrane structure damage, good thermal stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

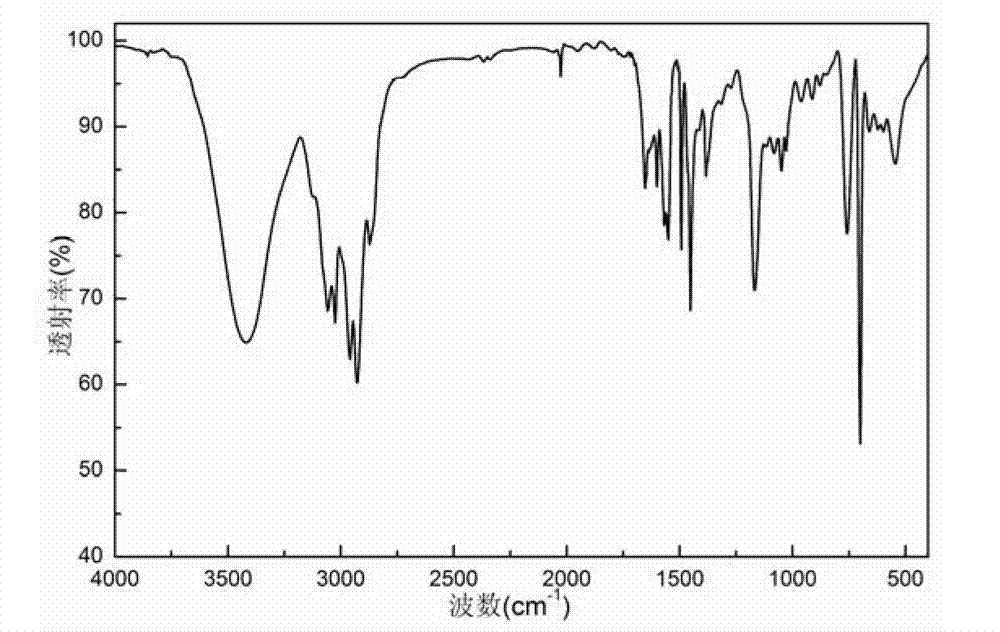

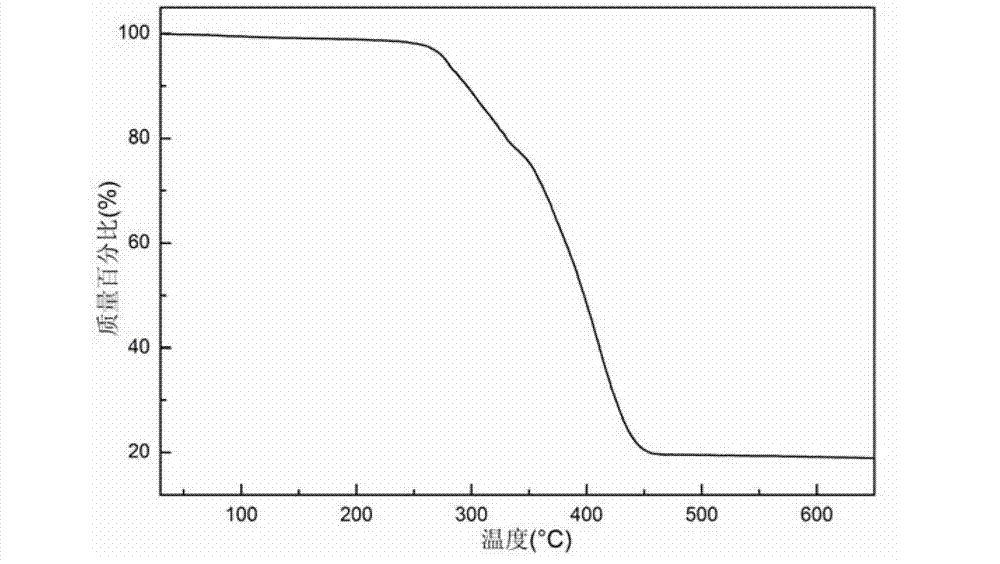

[0031] Take 0.01mol of 1-vinyl-3-butyl imidazole bromide and add it to a three-necked flask, then take 0.025mol of styrene, 10mL of ethanol and 0.015g of azobisisobutyronitrile, and place it under the protection of nitrogen at 65 ℃ in an oil bath with magnetic stirring and reflux for 24 hours. After the reaction, the obtained viscous liquid was transferred to a beaker, and vacuum-dried at 60° C. for 6 h. After drying, the product was washed with deionized water, soaked in tetrahydrofuran and washed repeatedly to remove unreacted monomers, and dried at 60°C to obtain a polymer containing imidazolium salt groups.

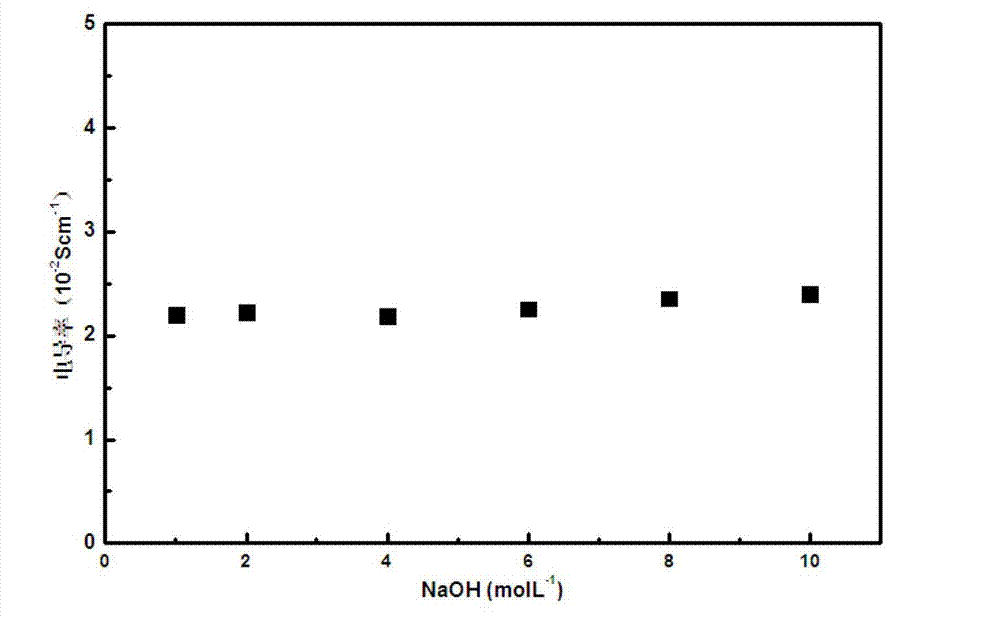

[0032] 0.6 g of the polymer containing imidazolium salt groups was fully dissolved in 15 mL of N,N-dimethylformamide, vacuum defoamed and cast on a clean glass plate to form a film, and dried at 80°C for 12 hours. The film was peeled off from the glass plate and placed in a 1mol / L NaOH solution. After soaking for 24 hours at room temperature, the NaOH in the film was...

Embodiment 2

[0037] The same method as in Example 1 was adopted, except that the monomer A used was 1-vinyl-3-methylimidazole iodide. The properties of the prepared membranes are listed in Table 1.

[0038] Table 1 Moisture content, ion exchange capacity and conductivity of membranes obtained by different monomer reactions

[0039] Example

Embodiment 3

[0041] The same method as in Example 1 was adopted, except that the monomer A used was 1-vinyl-3-ethyl imidazole bromide. The properties of the prepared membranes are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com