Production method of polyphenylene sulfide-based adsorption separation resin

A polyphenylene sulfide resin and polyphenylene sulfide-based technology, which is applied in the field of preparation of adsorption and separation functional resins, can solve problems such as single structure, low mechanical strength, poor thermal stability and chemical stability, and achieve excellent electrical properties, The effect of small molecular weight and good coordination and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

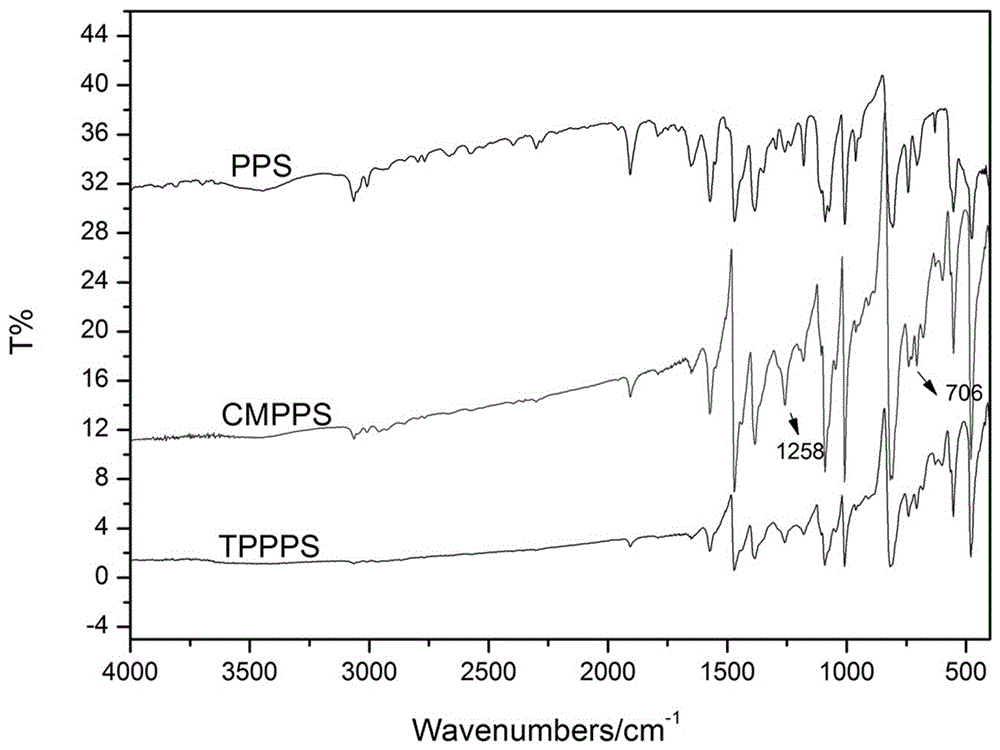

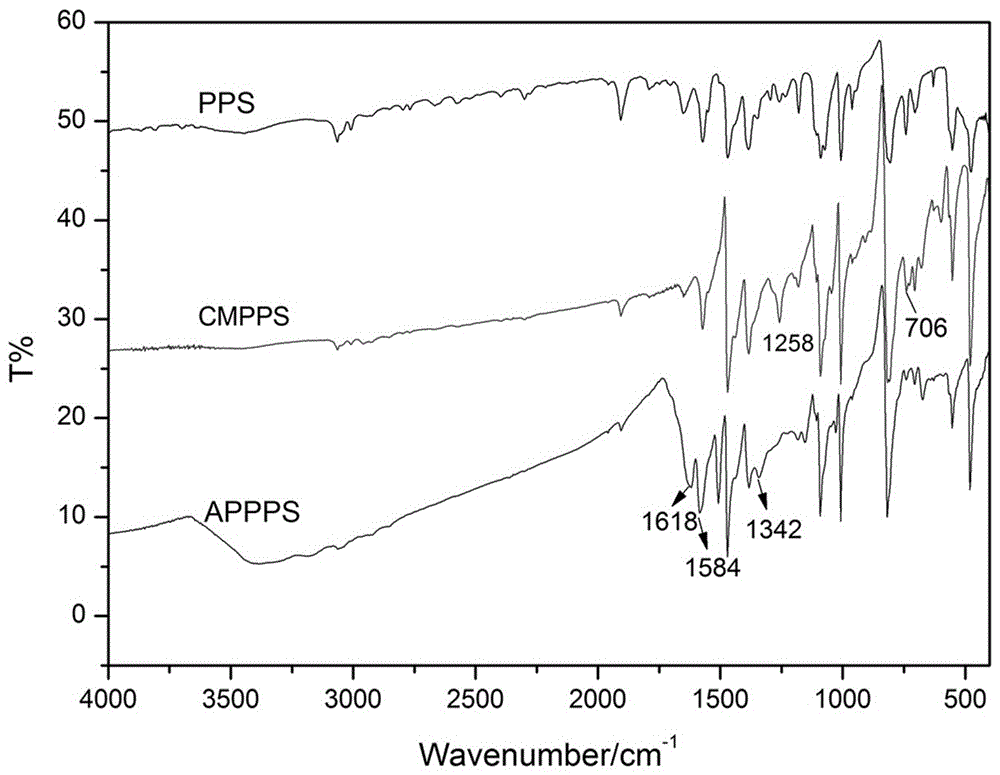

[0037] The preparation method of the polyphenylene sulfide-based thiophene adsorption separation resin (TPPPS) of the present invention, the detailed steps of the preparation method are as follows:

[0038] a. Synthesis of chloromethyl polyphenylene sulfide resin CMPPS:

[0039] First weigh 10.8726g of polyphenylene sulfide resin, pour it into a 500mL three-necked bottle, add 100mL of dichloroethane to swell at room temperature for 24h; then add 10mL of catalyst anhydrous tin tetrachloride and 100mL of methyl chloride, and heat up to Stir the reaction at 58°C for 48 hours, cool the resulting reaction solution after the reaction, pour out the mother liquor, and wash with 95% ethanol three times to remove excess dichloroethane and chloromethyl ether, and then use 200mL, 3mol / L HCl The ethanol aqueous solution (HCl ethanol aqueous solution is prepared by mixing concentrated hydrochloric acid, ethanol and water according to the volume ratio of 1:1:1) boiled for 4 hours, carried ou...

Embodiment 2

[0042] The preparation method of the polyphenylene sulfide-based thiophene adsorption separation resin (TPPPS) of the present invention, the detailed steps of the preparation method are as follows:

[0043] a. Synthesis of chloromethyl polyphenylene sulfide resin CMPPS:

[0044] First weigh 6.4836g of polyphenylene sulfide resin, pour it into a 250mL three-necked bottle, add 60mL of dichloroethane to swell at room temperature for 24h, then add 6.5mL of anhydrous tin tetrachloride catalyst and 60mL of chloromethyl ether, and heat up Stir the reaction at 58°C for 48 hours, and add 1 mL of anhydrous tin tetrachloride again at 24 hours of reaction; after the reaction, cool the resulting reaction solution, pour out the mother liquor, and wash with 95% ethanol three times to remove excess solvent. Chloroethane and chloromethyl ether, and then use 200mL, 3mol / L HCl ethanol aqueous solution (HCl ethanol aqueous solution is prepared by mixing concentrated hydrochloric acid, ethanol and...

Embodiment 3

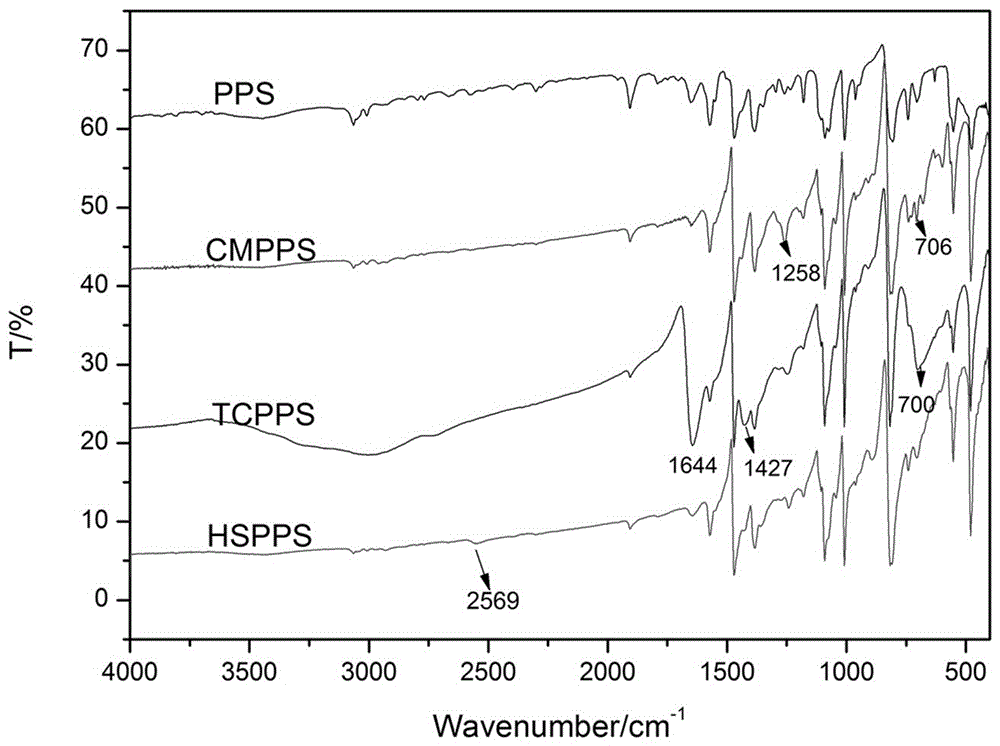

[0047] The preparation method of the polyphenylene sulfide-based adsorption separation resin of the present invention, that is, the mercapto resin (HSPPS), the detailed steps of the preparation method are as follows:

[0048] a. Synthesis of chloromethyl polyphenylene sulfide resin CMPPS:

[0049] First weigh 6.4836g of polyphenylene sulfide resin, pour it into a 250mL three-necked bottle, add 60mL of dichloroethane to swell at room temperature for 24h, then add 6.5mL of anhydrous tin tetrachloride catalyst and 60mL of chloromethyl ether, and heat up Stir the reaction at 58°C for 48 hours, and add 1 mL of anhydrous tin tetrachloride again when the reaction is 24 hours; after the reaction, cool the obtained reaction solution, then pour out the mother liquor, and wash with 95% ethanol three times to remove excess solvent Dichloroethane and chloromethyl ether, and then boil with 200mL, 3mol / L HCl ethanol water solution (HCl ethanol water solution is prepared by mixing concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com