Methyl aldehyde adsorbing substance and preparation method thereof

A technology for formaldehyde adsorption and formaldehyde, which is applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of low molecular weight of formaldehyde, poor purification effect, poor purification effect, etc., and achieve improved adsorption performance, The effect of promoting adsorption and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 11ml of polyethylene polyamine polymer with a molecular weight of 1800 and a concentration of 18% was fully mixed with 0.1ml of polyethylene glycol, and then diluted with 50ml of deionized water to prepare a formaldehyde reactant for future use. Take 70g of carbon molecular sieve, and bake it at a constant temperature of 150°C for 3 hours for pretreatment, in order to ensure that the formaldehyde reactant is more evenly loaded on the matrix material. Add the pretreated carbon molecular sieve to the formaldehyde reactant, keep the temperature at 70°C, rotate at 300rpm, and stir and impregnate for 5 hours. At this time, the formaldehyde reactant enters the internal pores of the carbon molecular sieve by natural diffusion and physically deposits on the matrix material. The formaldehyde adsorbent based on carbon molecular sieve is obtained by vacuum drying at 75° C., and the adsorption capacity of the adsorbent to formaldehyde is 0.4 mmol / g.

Embodiment 2

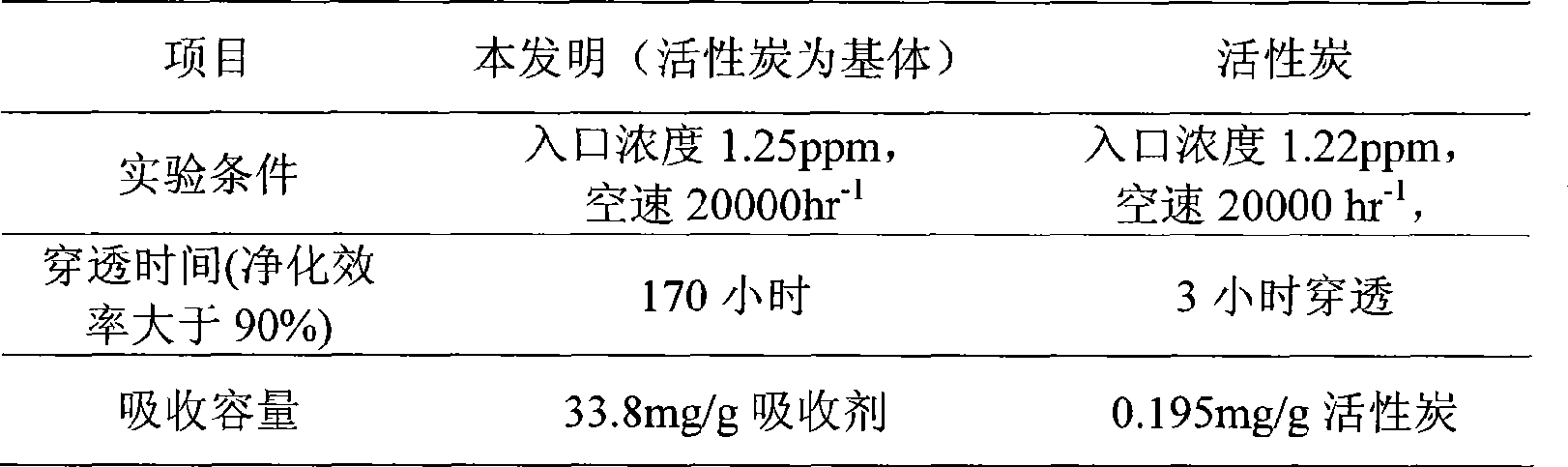

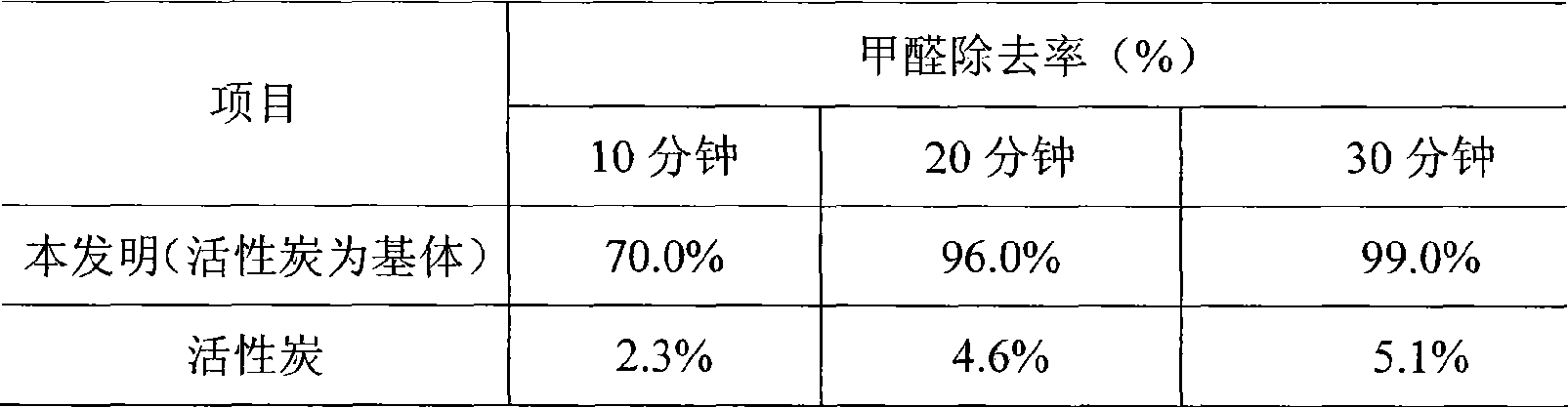

[0023] 13ml of polyethylene polyamine polymer with a molecular weight of 8000 and a concentration of 30% was fully mixed with 0.2ml of polyethylene glycol, and diluted with 20ml of deionized water to prepare a formaldehyde reactant. Take 20g of coal-based activated carbon, bake it at a constant temperature of 150°C for 4 hours for pretreatment, add it to the formaldehyde reactant, keep the temperature at 80°C, rotate at 150rpm, stir and impregnate for 5 hours, and then vacuum dry at 50°C to obtain formaldehyde adsorption with activated carbon particles as the matrix. agent, the adsorption capacity of formaldehyde is 1.5mmol / g.

Embodiment 3

[0025] Mix 20ml of polyethylene polyamine polymer with a molecular weight of 50,000 and a concentration of 20% with 0.5ml of polyethylene glycol, add 10ml of deionized water to dilute, and set aside. Take 6g of adsorption resin, wash it several times with deionized water, dry it by centrifugation, add it to the spare formaldehyde reactant, keep the temperature at 60°C, rotate at 100rpm, stir and impregnate for 12 hours, then vacuum dry at 45°C to obtain the adsorption resin as the matrix Formaldehyde adsorbent, the adsorption capacity of formaldehyde is 3.9mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com