Method for preparing carbon nano tube reinforced epoxy resin self repairing microcapsule

A technology of self-repairing microcapsules and carbon nanotubes, applied in the fields of national defense and organic composite materials, to achieve the effect of improving performance, easy operation and control, and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

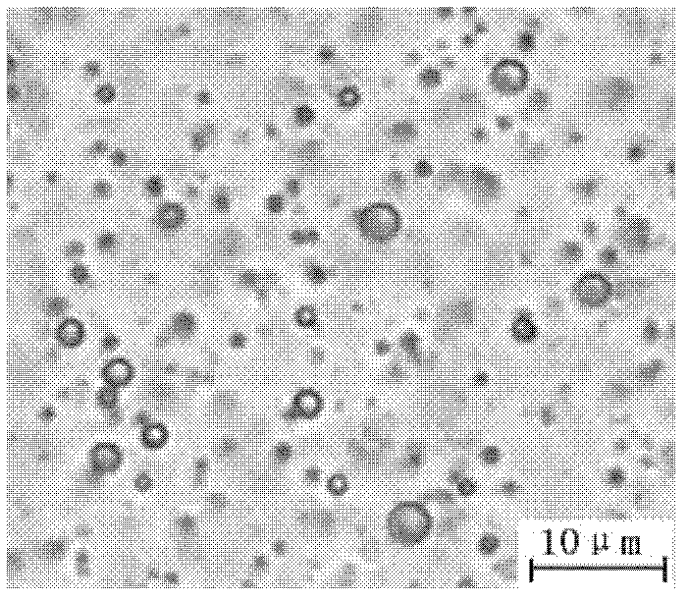

Image

Examples

Embodiment 1

[0017] Step 1, acidification of carbon nanotubes

[0018] Pure sulfuric acid and pure nitric acid were prepared into 240ml mixed strong acid at a volume ratio of 3:1, and 1g of carbon nanotubes were added to the mixed strong acid, dispersed in an ultrasonic (150W) water bath (65°C) for 6 hours, and left to stand for 5 hours. Extract the acidified carbon nanotubes, add deionized water to centrifuge and precipitate repeatedly, remove the acid remaining in the solution until the solution is basically neutral, and dry to remove water.

[0019] Step 2, preparation of epoxy resin-carbon nanotube emulsion

[0020] Mix Tween 20 and Span 60 at a mass ratio of 3:7 to form a compound emulsifier; mix 9g of epoxy resin with 1g of compound emulsifier, heat and stir in a water bath at 50°C, and the stirring speed is 3000rpm, slowly Add 30ml of deionized water dropwise to the mixture to form an epoxy resin emulsion after a certain period of time; add 0.001g of carbon nanotubes to the epoxy e...

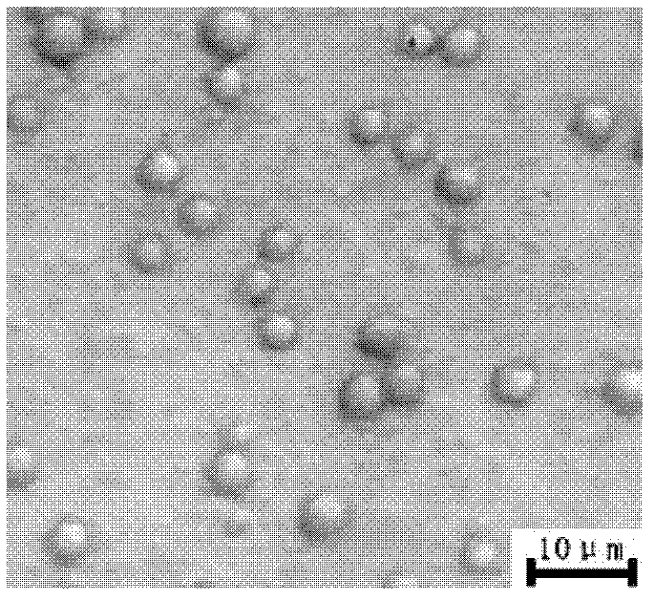

Embodiment 2

[0026] Step 1. Acidification of carbon nanotubes

[0027] Pure sulfuric acid and pure nitric acid were prepared into 240ml mixed strong acid at a volume ratio of 3:1, and 1g of carbon nanotubes were added to the mixed strong acid, dispersed in an ultrasonic (150W) water bath (65°C) for 6 hours, and left to stand for 5 hours. Extract the acidified carbon nanotubes, add deionized water to centrifuge and precipitate repeatedly, remove the acid remaining in the solution until the solution is basically neutral, and dry to remove water.

[0028] Step 2, preparation of epoxy resin-carbon nanotube emulsion

[0029] Mix Tween 20 and Span 60 uniformly at a mass ratio of 3:7 to form a compound emulsifier; mix 8.8g of epoxy resin with 1.2g of compound emulsifier, heat and stir in a water bath at 60°C, and the stirring speed is 2000rpm , slowly add 30ml of deionized water to the mixture, and form an epoxy resin emulsion after a certain period of time; add 0.004g of carbon nanotubes to the...

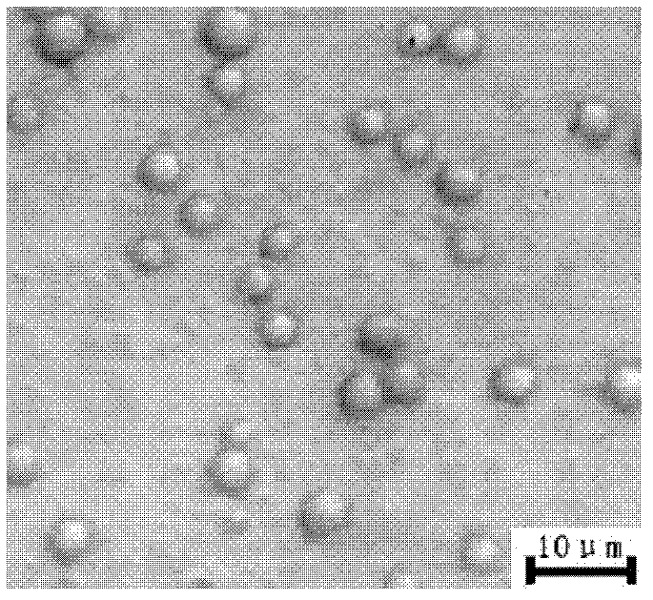

Embodiment 3

[0035] Step 1. Acidification of carbon nanotubes

[0036] Pure sulfuric acid and pure nitric acid were prepared into 240ml mixed strong acid at a volume ratio of 3:1, and 1g of carbon nanotubes were added to the mixed strong acid, dispersed in an ultrasonic (150W) water bath (65°C) for 6 hours, and left to stand for 5 hours. Extract the acidified carbon nanotubes, add deionized water to centrifuge and precipitate repeatedly, remove the acid remaining in the solution until the solution is basically neutral, and dry to remove water.

[0037] Step 2, preparation of epoxy resin-carbon nanotube emulsion

[0038]Mix Tween 20 and Span 60 uniformly at a mass ratio of 3:7 to form a compound emulsifier; mix 8.75g of epoxy resin with 1.25g of compound emulsifier, heat and stir in a water bath at 60°C, and the stirring speed is 2000rpm , slowly add deionized water to the mixture to form an epoxy resin emulsion after a certain period of time; add 0.005g of carbon nanotubes to the epoxy em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com