Preparation method and application of copper-based nanowire antibacterial material and preparation method of antibacterial melt-blown cloth

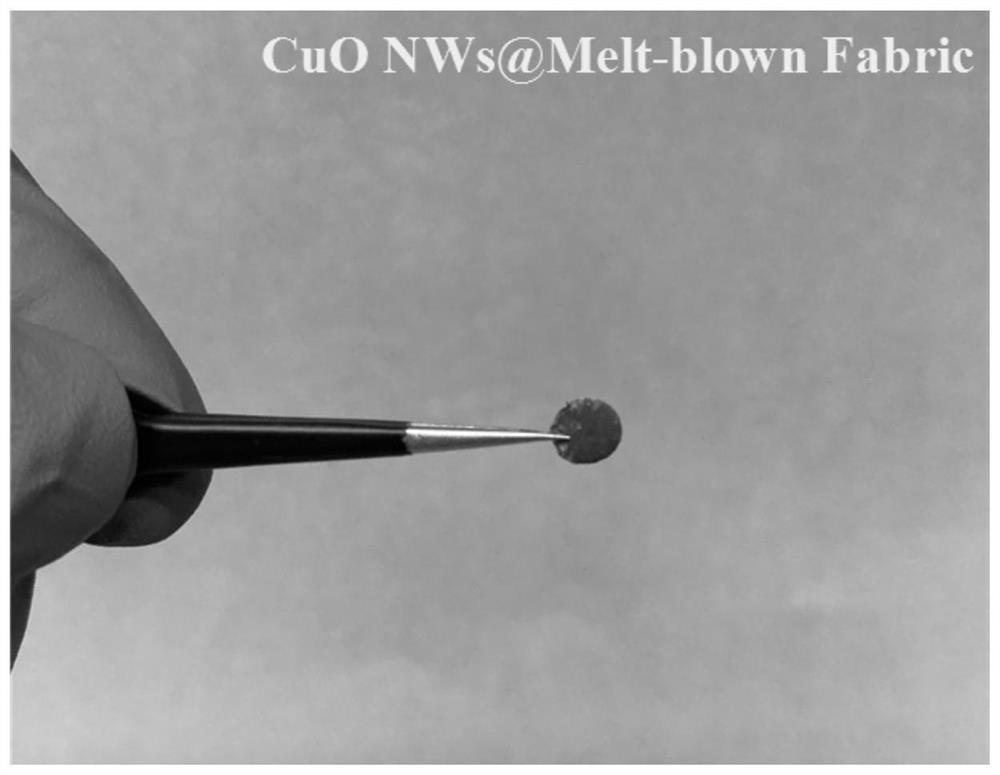

An antibacterial material and a technology of copper oxide nanowires, which are applied in the preparation of copper-based nanowire antibacterial materials and the preparation of antibacterial melt-blown cloth, can solve the problem of affecting the bactericidal performance, adhesion stability, insufficient copper-based nano-bactericidal performance, affecting melt-blown Cloth sterilization performance and other issues, to achieve strong copper ion release performance, significant antibacterial sterilization effect, stable and lasting effect of antibacterial sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a kind of preparation method of copper-based nanowire antibacterial material as described below, it comprises the following steps:

[0039] S100, preparing pure copper nanowires: using reducing agent and copper metal inorganic salt as raw materials, preparing pure copper nanowires by solvothermal method in a long-chain alkylamine solvent system;

[0040] S200, pickling of pure copper nanowires: take pure copper nanowires in a hydrophilic dispersion solvent, add weak acid solution for pickling;

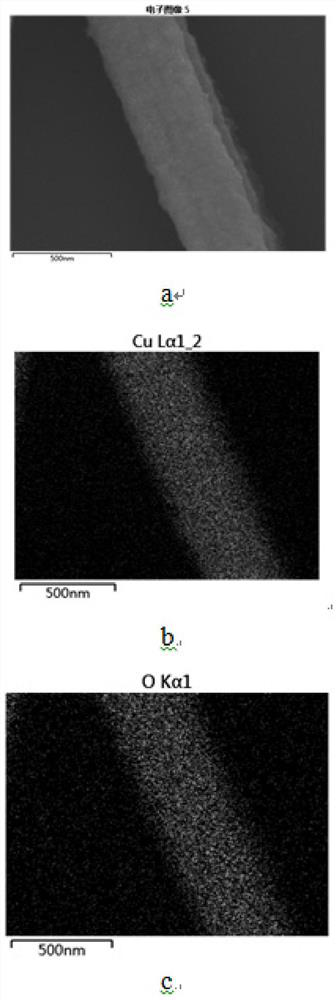

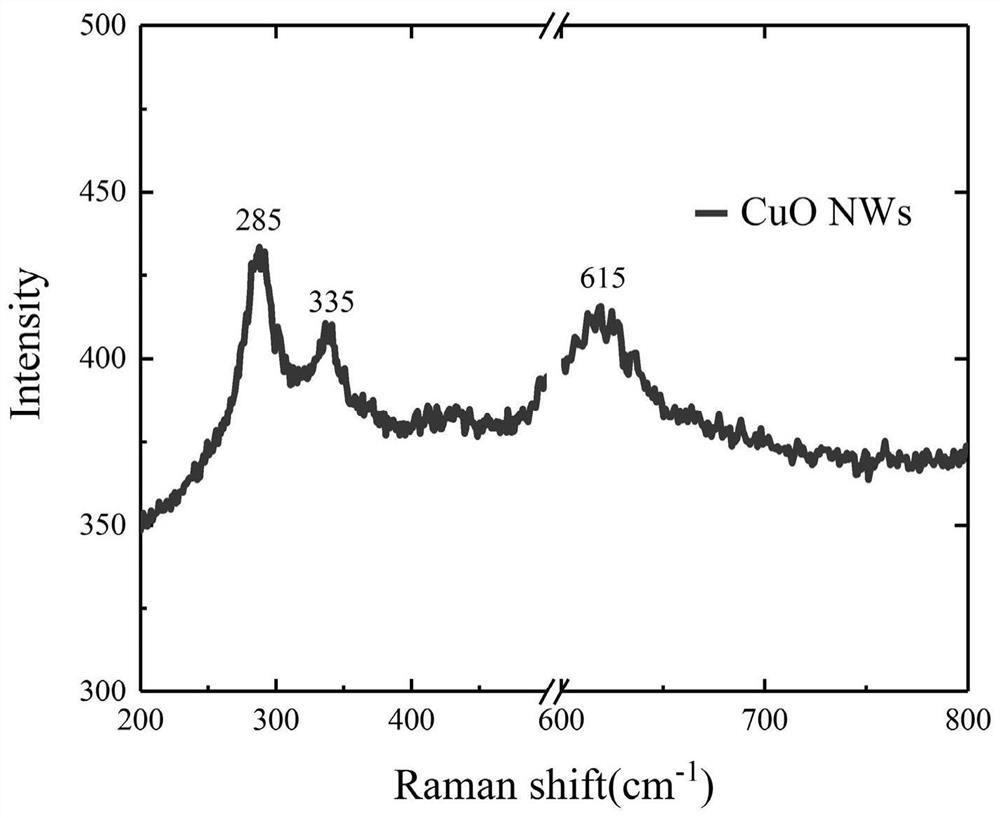

[0041] S300. Prepare copper oxide nanowires: take the pickled pure copper nanowires and oxidize them by liquid phase oxidation method, high temperature air oxidation method or CVD oxidation method to prepare copper oxide nanowires, that is, copper-based nanowire antibacterial materials.

[0042]Preferably, the reaction conditions of the solvothermal method are: in a protective atmosphere, react at a reaction temperature of 80-85°C for 10-15min, and...

Embodiment 1

[0076] 1. Preparation of pure copper nanowires: Accurately weigh 0.8 mmol of copper chloride dihydrate and 0.4 mmol of nickel acetylacetonate with an analytical balance, mix the two into a cleaned three-necked flask, and measure 10 mL of oleylamine with a plastic dropper , and pour it into a three-necked flask reaction device. Subsequently, the reaction device was placed in a constant temperature heating magnetic stirrer for heating reaction, and 50 sccm high-purity nitrogen gas was continuously fed into the reaction system as a protective gas. Adjust the constant temperature heating magnetic stirrer to preheat the reaction at 80°C for 10 minutes, exhaust the air inside the reaction device, and then continue to heat the reaction device to a constant temperature of 185°C for 4 hours. After the reaction, the system was naturally cooled to room temperature, the nitrogen input was turned off, and the pure copper nanowire solution in the three-necked flask, that is, the pure copper...

Embodiment 2

[0085] 1. Preparation of pure copper nanowires: Accurately weigh 0.8 mmol of copper chloride dihydrate and 0.4 mmol of nickel acetylacetonate with an analytical balance, mix the two into a cleaned three-necked flask, and measure 10 mL of oleylamine with a plastic dropper , and pour it into a three-necked flask reaction device. Subsequently, the reaction device was placed in a constant temperature heating magnetic stirrer for heating reaction, and 50 sccm high-purity nitrogen gas was continuously fed into the reaction system as a protective gas. Adjust the constant temperature heating magnetic stirrer to preheat the reaction at 80°C for 10 minutes, exhaust the air inside the reaction device, and then continue to heat the reaction device to a constant temperature of 185°C for 4 hours. After the reaction, the system was naturally cooled to room temperature, the nitrogen input was turned off, and the pure copper nanowire solution in the three-necked flask, that is, the pure copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com