Production method for low-shrinkage-rate wool fabric

A production method and technology of shrinkage rate, applied in the field of clothing fabrics, can solve the problems of easy yellowing, environmental pollution, dullness and other problems of wool fabrics, and achieve the effects of improving shrinkage resistance, avoiding damage and reducing shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

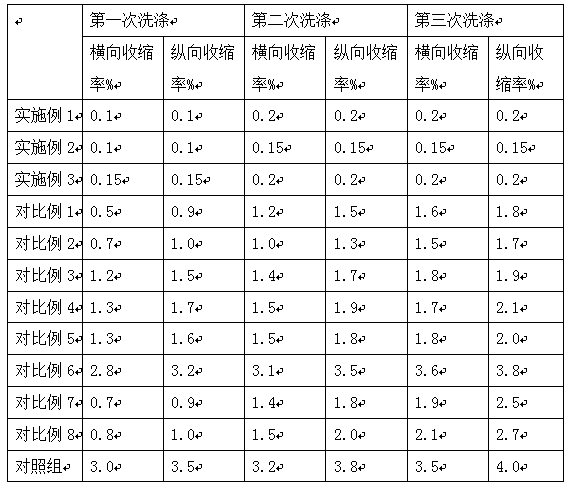

Examples

Embodiment 1

[0025] A kind of production method of the wool fabric of low shrinkage rate, concrete production method is as follows:

[0026] 1) Put the woolen fabric in a container, let in air with a temperature of 40°C and a relative humidity of 50% for humidification and preheating, and wait for the temperature and moisture content of the woolen fabric to be stable within 30 minutes, then add octadecyl Trimethylammonium chloride aqueous solution is atomized, mixed with air at a temperature of 60°C and a relative humidity of 70%, and then passed into the container to perform secondary humidification and preheating on the wool fabric. It can be stable within 30 minutes;

[0027] 2) Put the wool fabric that has been humidified and preheated into an airtight container, and use an ozone generator to pass ozone into the airtight container. After 1 hour of treatment, pressurize to 2MPa, keep the pressure for 30 minutes, and slowly release the pressure to normal pressure. Stand still at -5°C fo...

Embodiment 2

[0040] A kind of production method of the wool fabric of low shrinkage rate, concrete production method is as follows:

[0041] 1) Put the woolen fabric in the container, let in air with a temperature of 45°C and a relative humidity of 55% for humidification and preheating, and wait for the temperature and moisture content of the woolen fabric to be stable within 30 minutes, then add octadecyl The trimethylammonium chloride aqueous solution is atomized, mixed with air at a temperature of 65°C and a relative humidity of 75%, and then passed into the container to perform secondary humidification and preheating on the wool fabric. It can be stable within 30 minutes;

[0042] 2) Put the wool fabric that has been humidified and preheated into an airtight container, and use an ozone generator to inject ozone into the airtight container. After 1.5 hours of treatment, pressurize to 3MPa, keep the pressure for 40 minutes, and slowly release the pressure to normal pressure. Stand still...

Embodiment 3

[0055] A kind of production method of the wool fabric of low shrinkage rate, concrete production method is as follows:

[0056] 1) Put the woolen fabric in the container, let in air with a temperature of 50°C and a relative humidity of 60% for humidification and preheating, and wait until the temperature and moisture content of the woolen fabric are stable within 30 minutes, then add octadecyl The trimethylammonium chloride aqueous solution is atomized, mixed with air at a temperature of 70°C and a relative humidity of 80%, and then passed into the container to perform secondary humidification and preheating on the wool fabric. It can be stable within 30 minutes;

[0057] 2) Put the wool fabric that has been humidified and preheated into an airtight container, and use an ozone generator to pass ozone into the airtight container. After 2 hours of treatment, pressurize to 5MPa, keep the pressure for 30 minutes, and slowly release the pressure to normal pressure. Stand still at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com