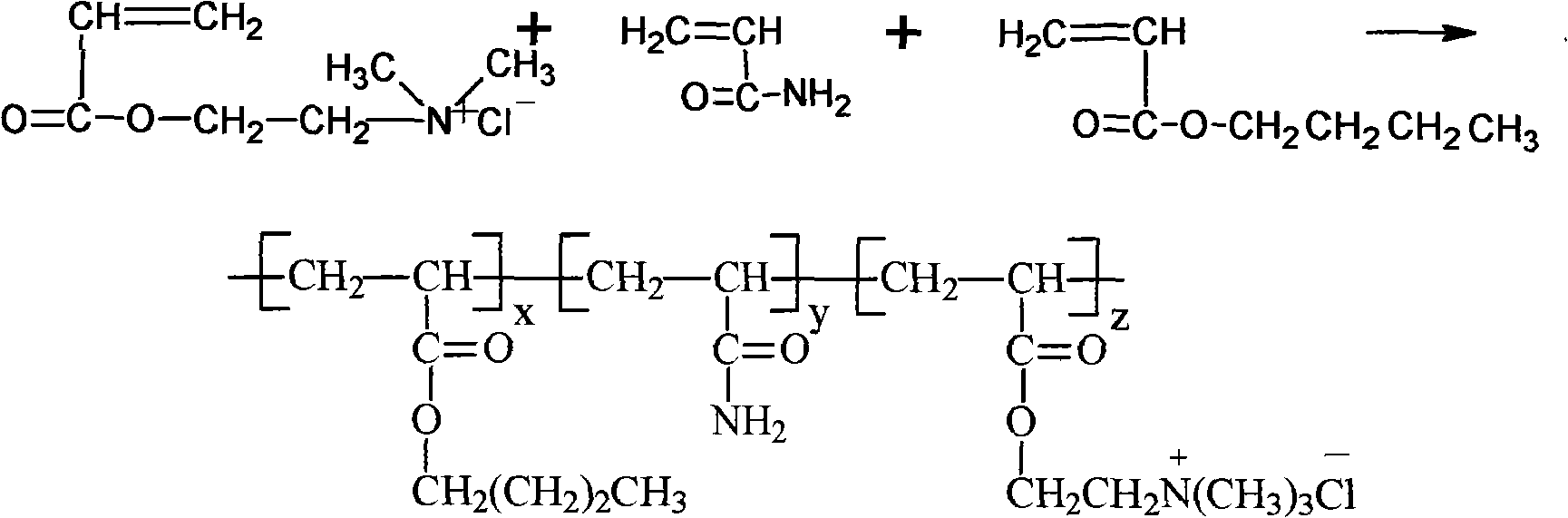

Method for preparing dewatered modified cation flocculating agent

A cationic flocculant, hydrophobic modification technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of small molecular weight of flocculant, long flocculation time, uneven molecular weight distribution, etc., to improve the relative molecular weight and enhance the adsorption capacity. , the effect of increasing the solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a. Add 12g of acrylamide and 0.2g of cetyltrimethylammonium bromide to a 250mL flask equipped with a stirrer, a thermometer, a feeding dropping funnel, and a nitrogen inlet and outlet, stir and dissolve with a small amount of water, and put In the ice-water mixture, pass nitrogen to remove oxygen, then add 9.2 mL of acryloyloxyethyltrimethylammonium chloride, and adjust the pH to 4 with HCl;

[0033] b. Add 1.2 g of butyl acrylate, add 36 mL of water, and continue stirring with nitrogen for 25 min;

[0034] c. Add 2.5 mL each of 1% sodium bisulfite, potassium persulfate, and urea aqueous solution, and 1.2 mL of 1% azobisisobutyronitrile, respectively, and seal it after stirring rapidly under nitrogen;

[0035] d. Freeze at -18°C until the solution freezes completely;

[0036] e. After completely dissolving at 30±2°C, let it stand for 4 hours to obtain a colorless colloidal flocculant;

[0037] The temperature of steps a, b, c is controlled at 1°C.

[0038] The intrin...

Embodiment 2

[0040] a. Add 6g of acrylamide and 0.5g of cetyltrimethylammonium bromide to a 250mL flask equipped with a stirrer, a thermometer, a feeding dropping funnel, and a nitrogen inlet and outlet, add a small amount of water and stir to dissolve, and put In the ice-water mixture, pass nitrogen to remove oxygen, then add 60 mL of acryloyloxyethyltrimethylammonium chloride, stir well, and adjust to pH = 5 with HCl;

[0041] b. Add 0.6g of butyl acrylate, add 70mL of water, and continue stirring with nitrogen for 30min;

[0042] c. Add 5.5mL each of 1% sodium bisulfite, potassium persulfate, and urea aqueous solution, and 3.0mL of 1% azobisisobutyronitrile respectively, stir rapidly under nitrogen, and then seal;

[0043] d. Freeze at -17°C until the solution freezes completely;

[0044] e. After completely dissolving at a room temperature of 30±2°C, let stand for 3.5 hours to obtain a colorless colloidal flocculant.

[0045] The temperature of steps a, b, c is controlled at 2°C.

...

Embodiment 3

[0048] a. Add 6g of acrylamide and 0.5g of cetyltrimethylammonium bromide to a 250mL flask equipped with a stirrer, a thermometer, a feeding dropping funnel, and a nitrogen inlet and outlet, add a small amount of water and stir to dissolve, and put In the ice-water mixture, pass nitrogen to remove oxygen, then add 60 mL of acryloyloxyethyltrimethylammonium chloride, stir well, and adjust to pH = 5 with HCl;

[0049] b. Add 1.2 g of butyl acrylate, add 70 mL of water, and continue stirring with nitrogen for 25 min;

[0050] c. Add 5.8mL each of 1% sodium bisulfite, potassium persulfate, and urea aqueous solution, and 3.2mL of 1% azobisisobutyronitrile, stir rapidly under nitrogen, and then seal;

[0051]d. Freeze at -16°C until the solution freezes completely;

[0052] e. After completely dissolving at room temperature 30±2°C, let stand for 3 hours to obtain a colorless colloidal flocculant.

[0053] The temperature of steps a, b, c is controlled at 3°C.

[0054] The intrins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com