Preparing method for superfine silver powder

A technology of ultra-fine silver and silver nitrate, which is applied in the field of silver powder production equipment, can solve the problems of widening particle size range, large variation of silver powder particles, and inability to ensure constant solution concentration, and achieve the effect of simple and convenient operation and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of described silver ammonium ion solution is as follows: according to the mass ratio of silver nitrate and deionized water, silver nitrate is dissolved in deionized water according to the mass ratio of silver nitrate and deionized water, and silver nitrate solution is obtained after the dissolution is complete. The silver nitrate solution is ammonia water with a volume ratio of 1:2, and the stirring is continued until the solution is constant to a transparent solution, and the silver ammine ion solution is obtained.

[0030] The aqueous dispersant solution is prepared by the following method: adding the natural macromolecular water-soluble colloid to deionized water according to the mass ratio of the natural macromolecular water-soluble colloid to deionized water at a ratio of 1:50, stirring and dissolving, and preparing a colloid solution.

[0031] The hydrazine hydrate aqueous solution is prepared by the following method: add deionized water to ...

Embodiment 1

[0041] Such as figure 1 Shown, a kind of preparation method of superfine silver powder specifically comprises the following steps:

[0042] S1) Dissolve 5000g of silver nitrate in 10L of water. After the dissolution is complete, add 5L of ammonia water with a content of 20-35% under stirring conditions. At this time, you will see that the solution first turns transparent to brown, and then gradually turns from brown to transparent solution. Then Add deionized water to dilute the solution to 15L to obtain a silver ammonium ion solution, which is set aside;

[0043] Add 1000g of natural macromolecular water-soluble colloid into 50L of deionized water, stir and dissolve, and prepare a colloid solution to obtain an aqueous dispersant solution for subsequent use;

[0044] Add 2200 g of hydrazine hydrate solution with a content ≥ 80% into deionized water to prepare a 10 L solution to obtain an aqueous hydrazine hydrate solution for later use.

[0045] S2) The prepared silver ammoniu...

Embodiment 2

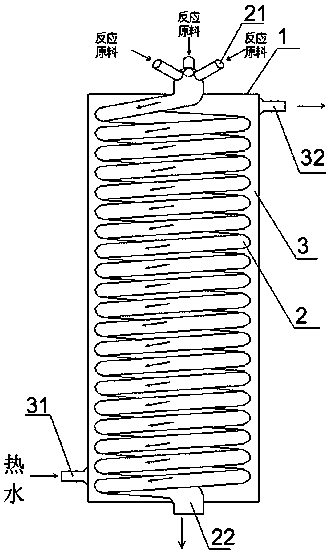

[0049] This embodiment is improved on the basis of Embodiment 1. The improvement is that: the reactor body also includes a temperature adjustment chamber 3 arranged between the shell 1 and the reaction chamber 2, and the two ends of the temperature adjustment chamber 3 A liquid inlet 31 and a liquid outlet 32 are respectively provided.

[0050] The upper and lower ends of the shell 1 are respectively connected to the two ends of the reaction pipeline near the feed port 21 and the discharge port 22, so that the shell 1 is sleeved on the outer surface of the reaction pipe. The temperature adjustment chamber 3 can adjust the temperature of the reaction raw materials in the reaction pipeline by flowing hot water through the liquid inlet 31 and then flowing out from the liquid outlet 32, so that the reaction raw materials can complete the reaction at a constant temperature.

[0051] The liquid inlet 31 is located at the lower end of the temperature adjustment chamber 3 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com