Storage lubricating grease and method for preparing same

A technology of lubricating grease and lubricating oil base oil, which is applied in the field of lubricating oil, can solve the problems that the anti-rust oil cannot meet the requirements of long-term storage and sealing, the storage conditions cannot meet the requirements, and the corrosion loss of threaded steel is serious. Good performance and low evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

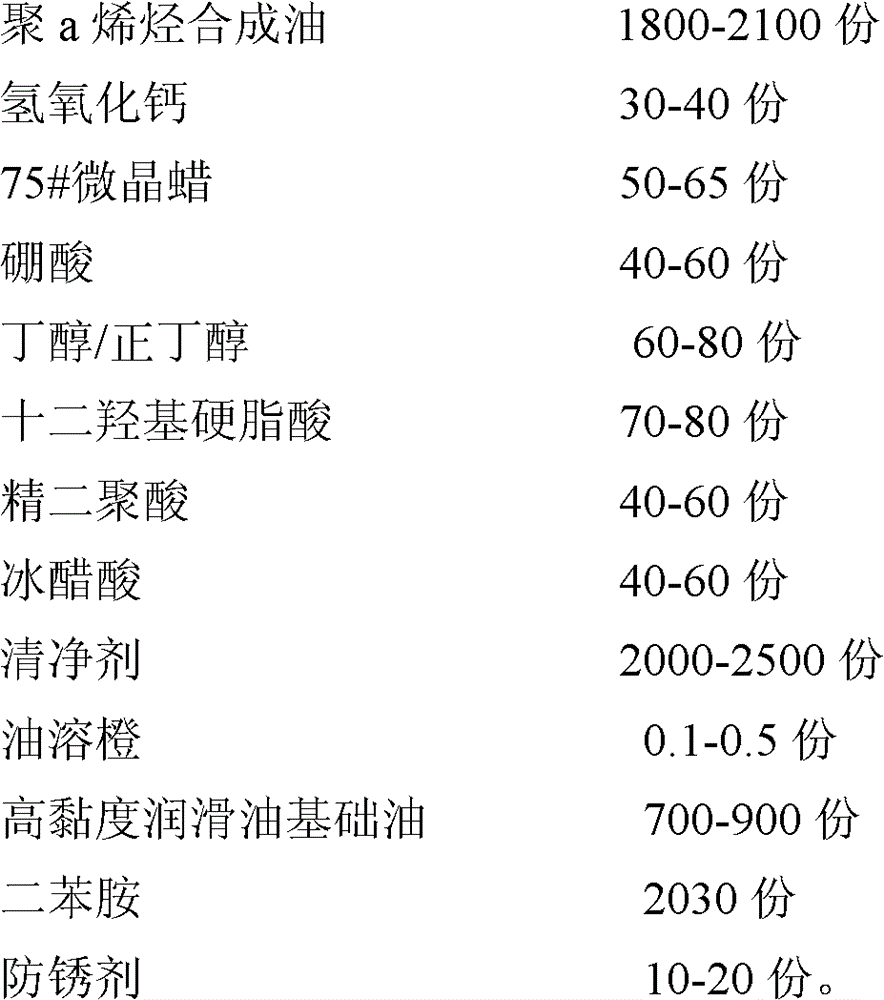

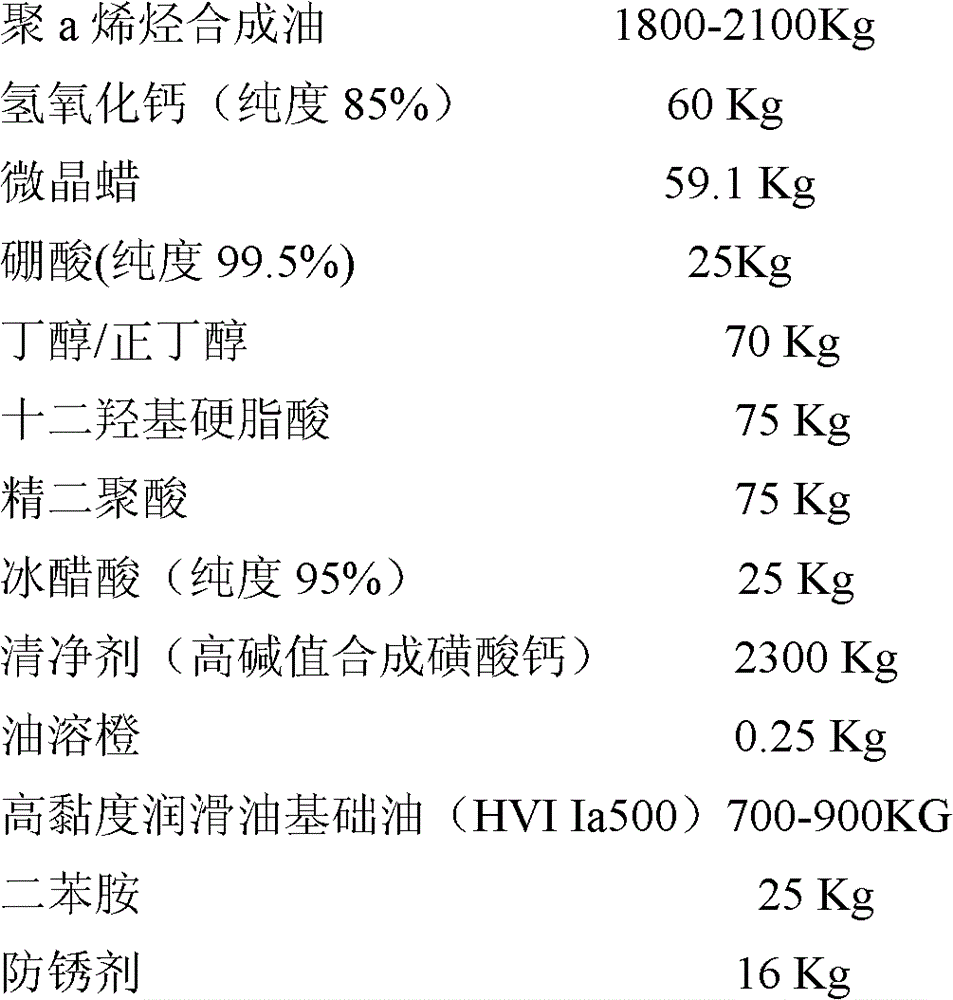

[0019] A kind of storage grease, its composition and weight are as follows:

[0020]

[0021] The finished product made from the above raw materials is 5.5-6.2 tons. For microcrystalline wax, it is recommended to use microcrystalline wax with a melting point of 75°C, which is a commercially available product.

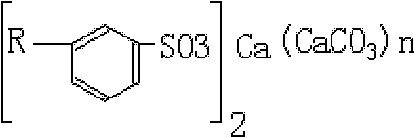

[0022] Wherein the molecular formula of detergent:

[0023]

[0024] R is an alkyl group, including: -CH 3 ,-CH 2 CH 3 ,-C 3 h 7 Wait

[0025] Anti-rust agent (T746) function is: good oil solubility, protect the metal surface from rust and corrosion, is an excellent anti-rust agent for oil products, widely used in the preparation of steam turbine oil, oil for machine tools, hydraulic oil, hydraulic transmission oil, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com