Energy saving apparatus for flocculation of industrial waste liquid

A technology of industrial waste liquid and energy-saving devices, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high energy consumption, achieve energy saving and good flocculation effect , the effect of prolonging the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

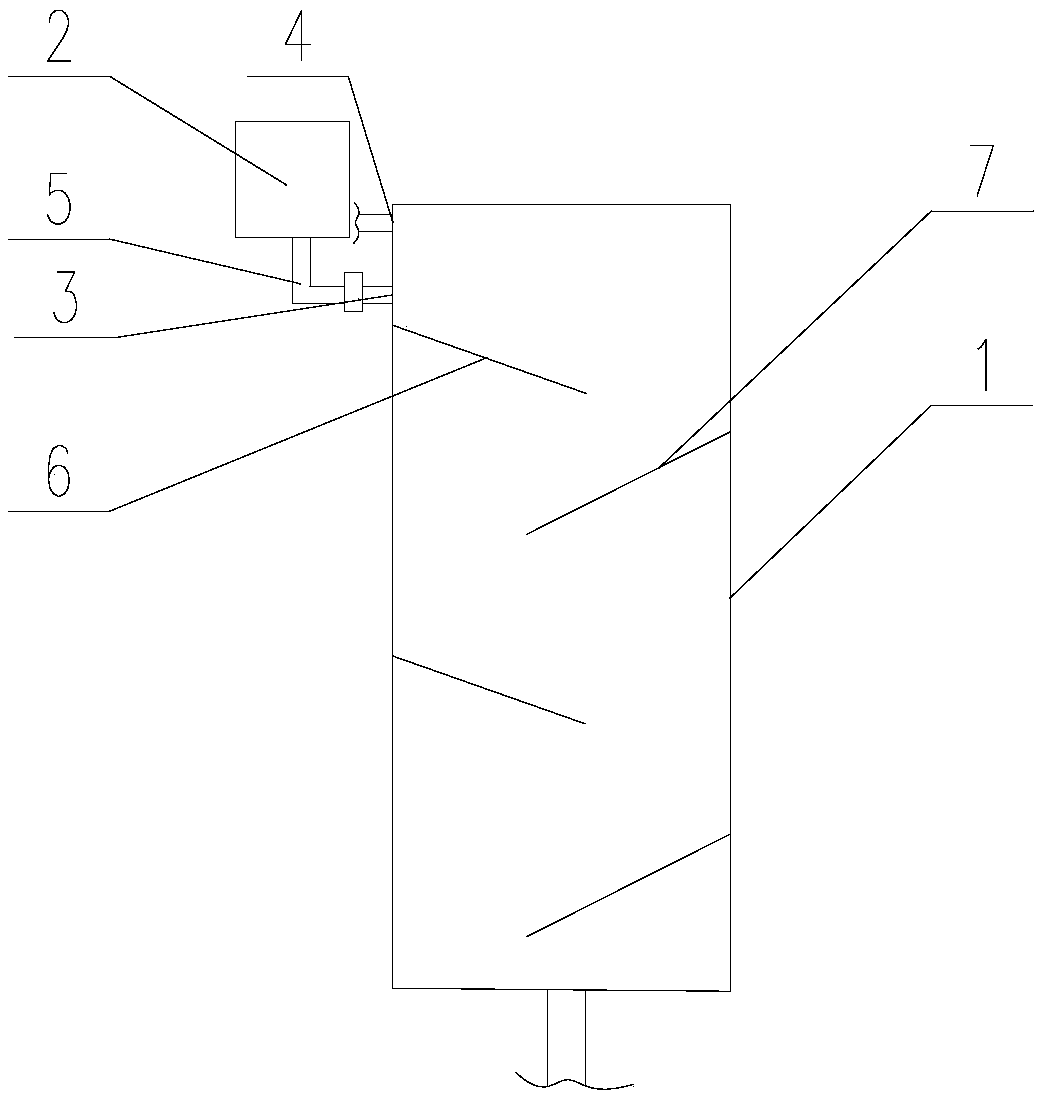

[0020] Such as figure 1 and figure 2 As shown, an energy-saving device for flocculation of industrial waste liquid includes a flocculant high-level tank 2, a central delivery pipe 1, a flocculant addition port 3 and a waste liquid addition port 4, and the lower end of the flocculant high-level tank 2 is connected with a flocculant addition pipe 5. The outlet end of the flocculant addition pipe 5 is connected to the flocculant addition port 3 through a flange, the flocculant addition port 3 and the waste liquid addition port 4 are arranged at the upper end of the central addition pipe, and the waste liquid addition port 4 Located above the flocculant addition port 3, the inner wall of the central conveying pipe 1 is provided with a plurality of first baffles 6 and a plurality of second baffles 7 that are inclined downward and form an excellent arc. The first baffles 6 and The arc surface end of the second baffle plate 7 is in full contact with and fixed to the inner wall of t...

Embodiment 2

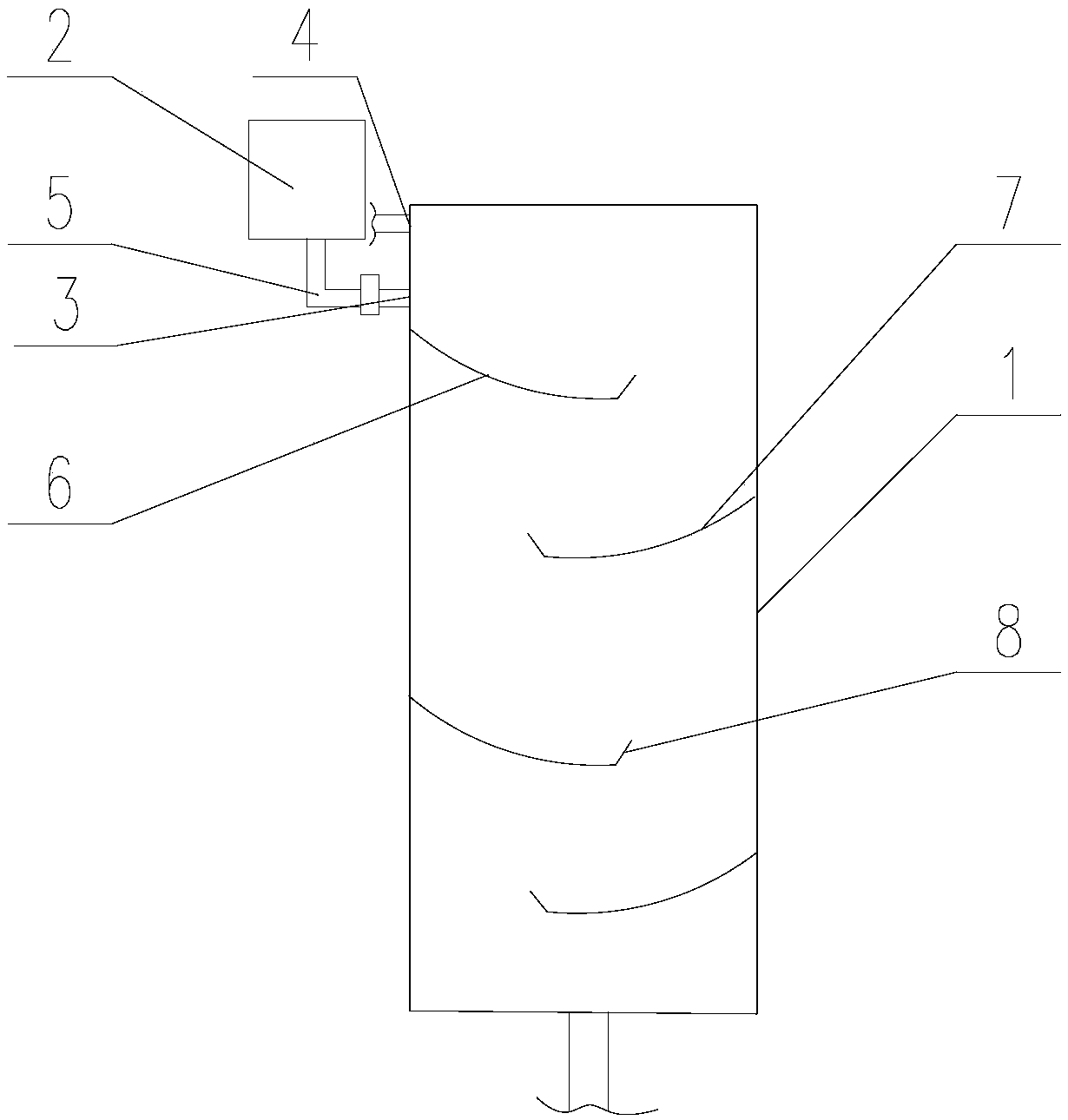

[0023] Such as figure 1 and figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the first baffle plate 6 and the second baffle plate 7 are bent into curved surfaces with their recesses facing upward. In this way, the mixing contact time between the mixing liquid and the baffle is guaranteed to be longer and the mixing is more thorough.

[0024] The free ends of the first baffle plate 6 and the second baffle plate 7 are provided with an upwardly tilted baffle plate 8, which can slow down the flow velocity of the mixed liquid reaching the baffle plate downward, and the liquid that continues to flow on it This part of the mixed liquid will generate momentum and play the role of mixing. When the liquid in this baffle flows to the next baffle, it will accelerate due to the action of gravity, and the flow rate will increase. This can not only prolong the mixing time, but also can Get a steady stream of momentum, making the mixing effect similar to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com