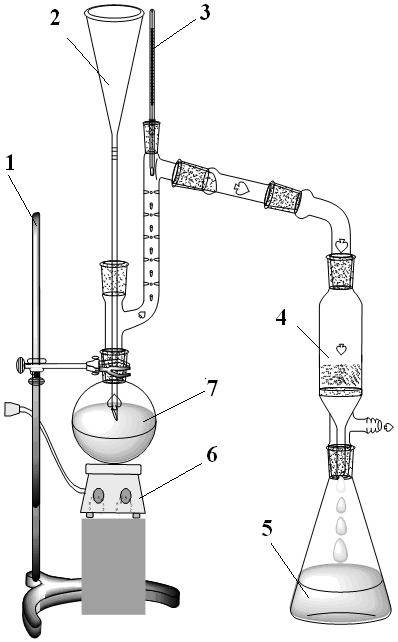

Device and method for determining total alkalinity and residual silica content of used sodium silicate-bonded sand or reclaimed sodium silicate-bonded sand

A silicon dioxide and measuring device technology, applied in the preparation of test samples, chemical analysis by titration, etc., can solve problems such as failure to provide the method of silicon dioxide content, and achieve good reproducibility and complete dissolution , the result is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

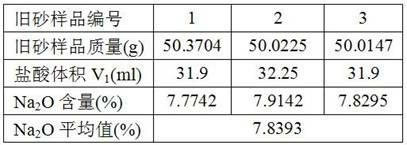

[0025] Weigh the old water glass sand samples three times, and prepare and analyze the liquid samples according to the aforementioned method respectively, and the steaming time is 50 minutes. Obtain about 100 ml of the sample, and then directly titrate the sample, the concentration of hydrochloric acid used is c=0.3960 mol / L, and the indicator is a mixed indicator of methyl red-bromocresol green; the analysis steps are as described above, and the titration analysis results are shown in the following table shown.

[0026]

Embodiment 2

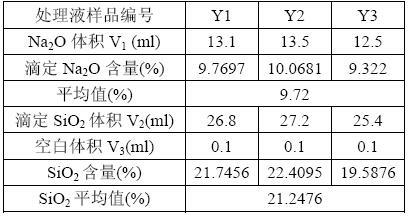

[0028] Weigh 430.2645 grams of the old sand sample of water glass, prepare and analyze the liquid sample according to the aforementioned method, and the steaming time is 60 minutes. Obtain about 522.8 ml of the sample, then use a pipette to pipette 20 ml of the sample for titration, the concentration of hydrochloric acid used is c=0.3960 mol / L, the amount of NaF added is 2 g, and the NaF blank sample V 3 =1 ml), sampled and analyzed three times, the indicator was a mixed indicator of methyl red-bromocresol green.

[0029] 1) Add cresol green-methyl red mixed indicator (three parts of 1g / L bromocresol green ethanol solution, one part of 2g / L methyl red ethanol solution) as titration indicator.

[0030] 2) Titration of Na 2 O: Titrate with 0.5 mol / l hydrochloric acid solution. When the color of the solution changes from green to red, it is the titration end point. The volume of the consumed hydrochloric acid standard solution is recorded as V m1, and this solution continues to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com