Preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring

A mechanical stirring, high-load technology, used in food preparation, food forming, food ingredients as pH modifiers, etc., can solve the problem of data and examples for measuring the resistance to mechanical damage, long reaction time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

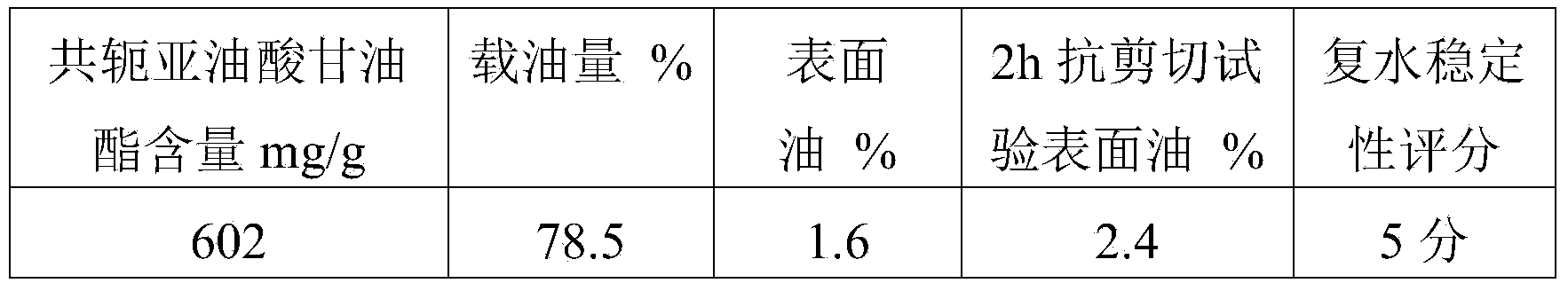

Embodiment 1

[0042] Dissolve 6kg of calcium caseinate in 245kg of water at 60°C, and after complete dissolution, add 0.02kg of sodium hydroxide to adjust the pH value of the solution until the final pH=7.0, stir and react at 60°C for 4 hours, then add 34kg of malt paste to the reaction solution Jing and 1kg of sodium tripolyphosphate were stirred and dissolved to obtain a water phase, and the temperature of the water phase was 60°C;

[0043] Add 2kg monoglycerides, 0.6kg mixed tocopherols and 0.38kg sunflower phospholipids to the conjugated linoleic acid glycerides, raise the temperature to 75°C, stir and dissolve to obtain an oil phase, and cool the oil phase to 60°C;

[0044] Slowly add the oil phase at 60°C to the water phase and mix, mechanically stir at 150rpm and 60°C for 1 hour, and then homogenize twice under high pressure at 50Mpa to obtain a homogeneous emulsion with an oil droplet diameter D50 of 460nm; the homogeneous emulsion is sprayed Dried in a drier, the spray drying condi...

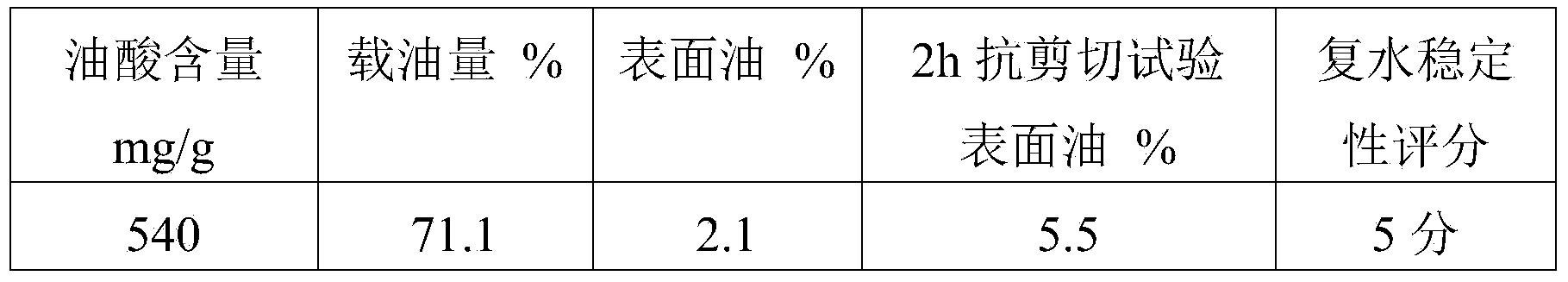

Embodiment 2

[0049] Dissolve 50kg of casein in 500kg of water at 70°C. After it is completely dissolved, add 10kg of calcium chloride to adjust the pH of the solution. The final pH is 12. After reacting at 70°C for 1 hour, add 2.5kg of dipotassium hydrogen phosphate, 5kg of Sucrose ester and 80kg trehalose were stirred and dissolved for 1 hour to obtain a water phase, and the temperature of the water phase was 70°C;

[0050] Add 1kg mixed tocopherols and 1.5kg soybean lecithin to 350kg high oleic sunflower oil (oleic acid content is 78%), stir at 60°C for 30min to obtain the oil phase;

[0051] Slowly add the oil phase to the water phase and mix, stir at 63rpm and 70°C for 1 hour to emulsify, and then homogenize twice under high pressure at a homogenizing pressure of 50Mpa to obtain a homogeneous emulsion with an oil droplet size of D50 of 310nm; Drying in a spray dryer, the spray drying condition is 170° C. of air inlet temperature and 78° C. of outlet air temperature to obtain high oleic...

Embodiment 3

[0056] Dissolve 26.1kg of soybean protein isolate in 370kg of water at 50°C, add 0.9kg of sodium tripolyphosphate, and add 3.0kg of calcium hydroxide to adjust the pH of the solution after it is completely dissolved. The final pH of the solution is 9.0, and react at 50°C for 0.5h Add 69kg of maltooligosaccharide, stir and dissolve for 0.5h to obtain a water phase, and the temperature of the water phase is 50°C.;

[0057] Add 0.3kg of mixed tocopherols and 0.2kg of sunflower phospholipids to 210kg of soybean oil, heat up to 50°C, stir and dissolve to obtain an oil phase, keep it warm at 50°C for use;

[0058] Slowly add the oil phase to the water phase and mix, stir at 97rpm and 50°C for 1 hour, and homogenize twice under high pressure at a homogeneous pressure of 50Mpa. The homogeneous emulsion is dried in a spray dryer, and the spray drying condition is an inlet air temperature of 180 ℃, the air outlet temperature is 75 ℃, and soybean oil microcapsule powder is obtained, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com