Vacuum chamber electrode extraction device

A technology of electrode extraction and vacuum chamber, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as vacuum sealing, achieve low cost, strong function, and solve the effect of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

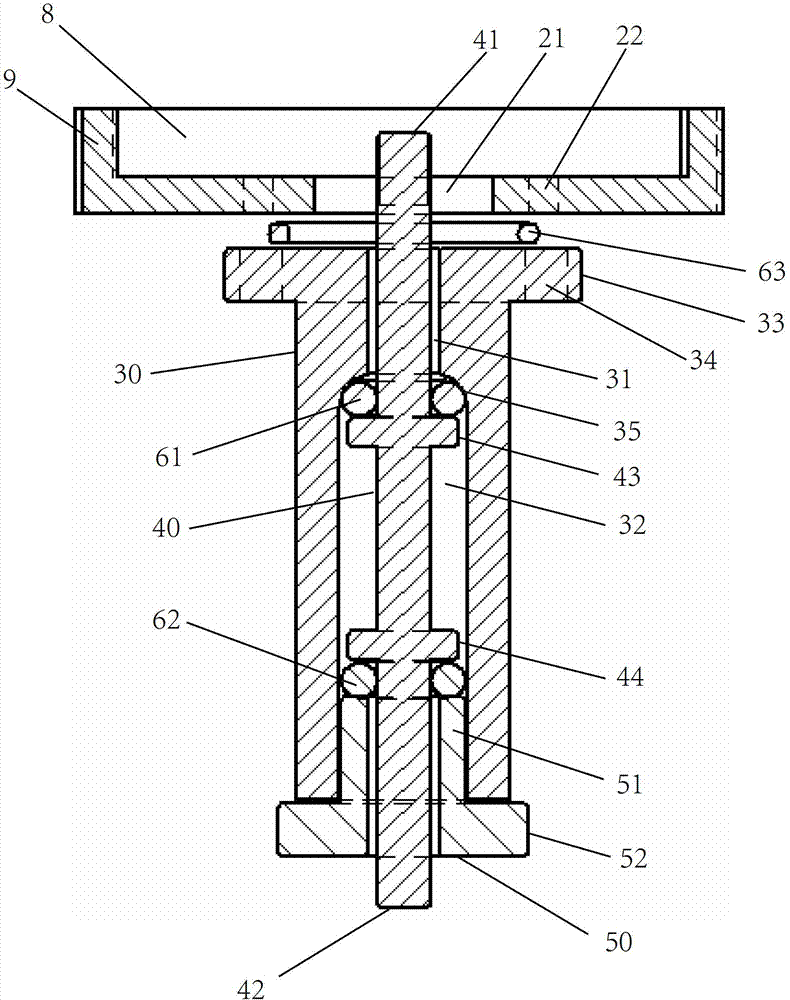

[0030] The invention moves the electrode lead-out device from the inside of the chamber to the outside, and at the same time moves the sealing and insulating parts to the outside of the chamber, changing from a high temperature environment to a normal temperature environment, and adopts a double rubber sealing ring structure instead of the original metal sealing and insulation structure, saving energy Structural costs and maintenance costs.

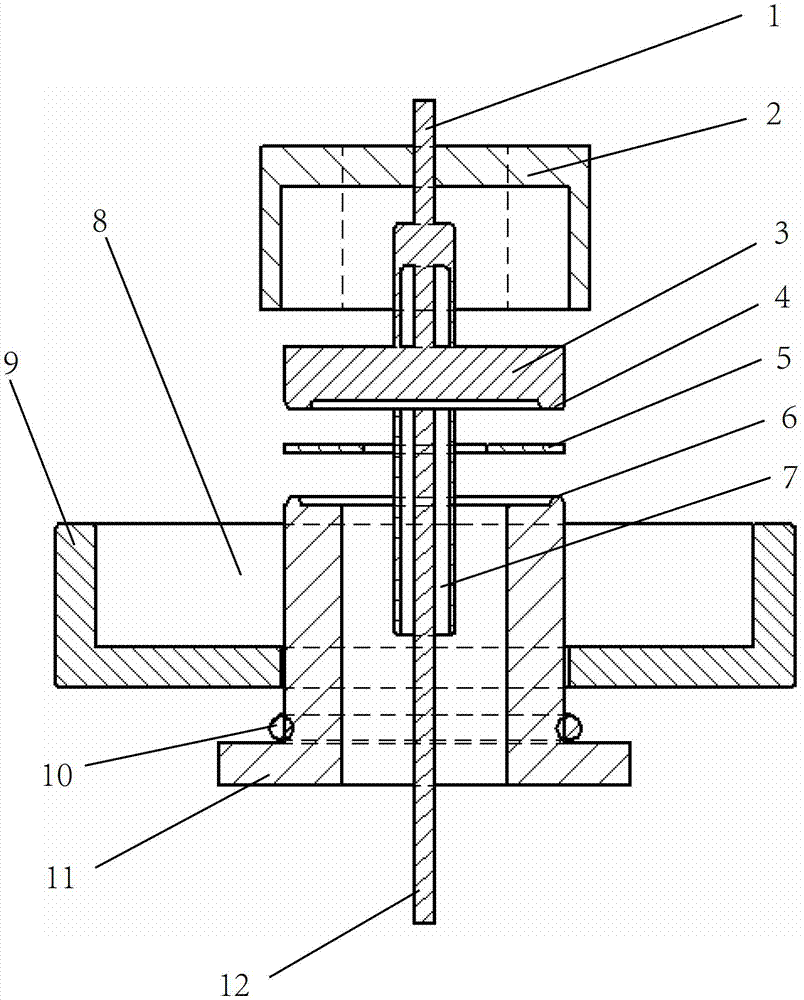

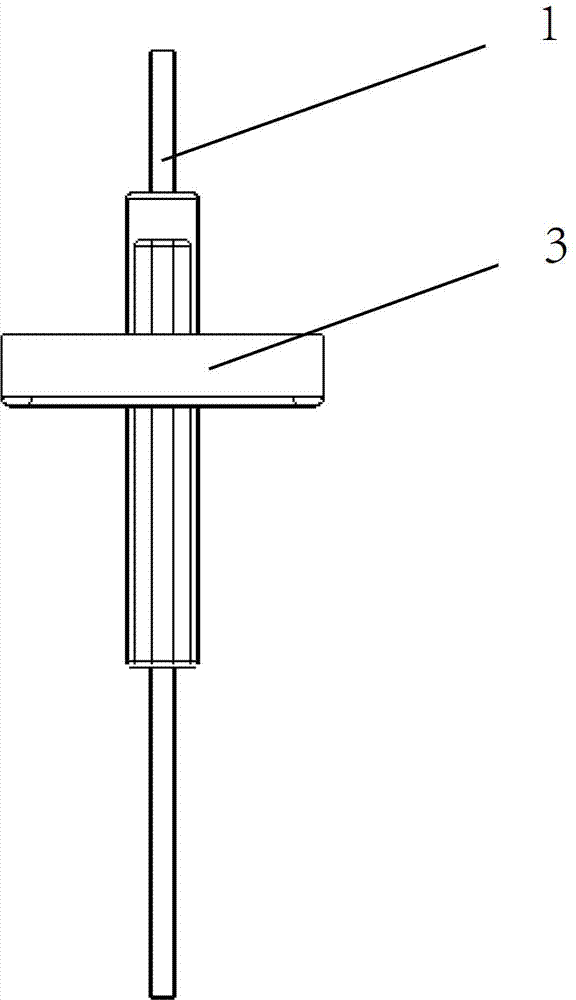

[0031] The vacuum chamber electrode lead-out device provided by the present invention, such as figure 2 , Figure 2A As shown, it mainly includes an extraction device base 30, an internal electrode 40 and an electrode fixing locking cap 50, wherein:

[0032] The vacuum chamber 8 has a chamber bottom plate 9, and a central hole 21 and several fixing holes 22 arranged around the central hole 21 are provided on the chamber bottom plate 9;

[0033] The base 30 of the extraction device is provided with a stepped through hole, and the steppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com