Diesel engine flame ring disassembling tool and disassembling method

A technology for dismantling tooling and diesel engines, applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems such as affecting diesel engine maintenance operations, time-consuming and laborious disassembly methods, and easily damaged screws, etc., to improve maintenance efficiency and maintenance quality, reduce labor intensity, The effect of simple tooling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

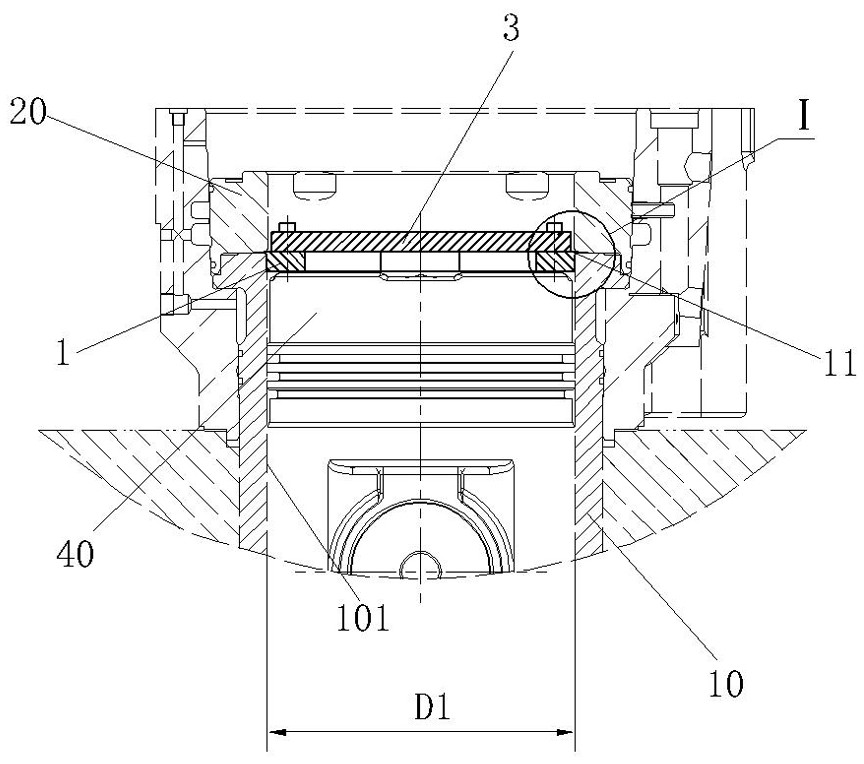

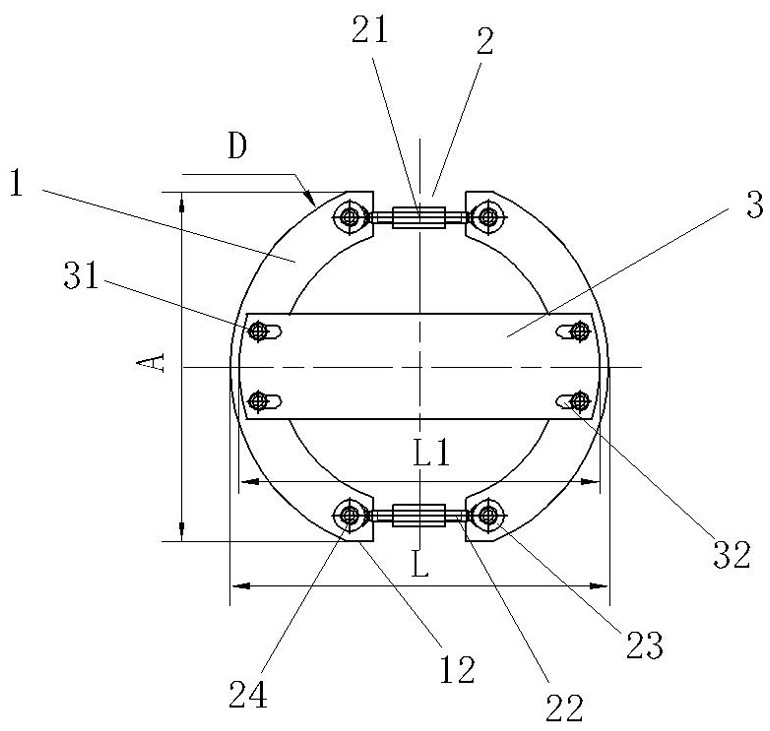

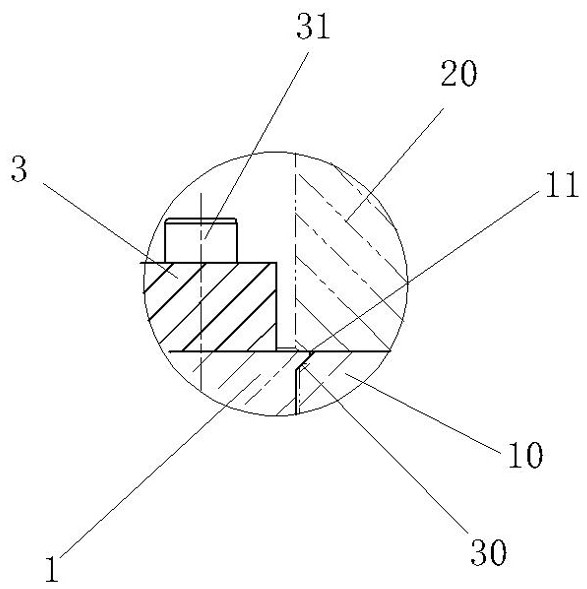

[0023] like Figure 1 ~ Figure 3 As shown, this embodiment includes a pair of arc-shaped plates 1, two arc-shaped plate connecting mechanisms 2 and a connecting plate 3, the end faces of a pair of arc-shaped plates 1 are oppositely arranged, and the two ends of the connecting plate 3 are respectively fixed on On the middle part of the pair of arc-shaped plates 1, the upper sides of the two ends of the pair of arc-shaped plates 1 are respectively fixedly connected by the arc-shaped plate connecting mechanism 2, and the outer circle of the pair of arc-shaped plates 1 after the fixed connection is connected with the cylinder liner The inner hole 101 matches and is slightly smaller than the inner diameter of the cylinder liner, which is convenient for putting the flame ring removal tool of the present invention into the inner hole 101 of the cylinder liner....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com