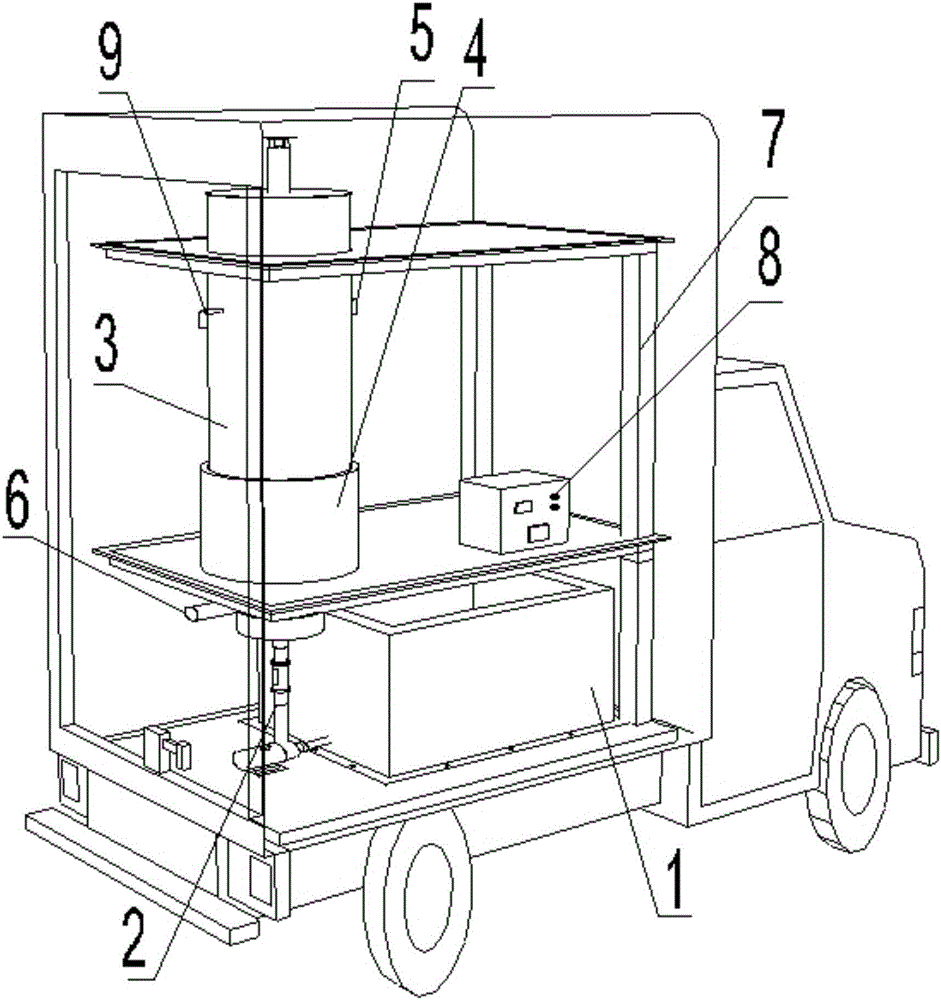

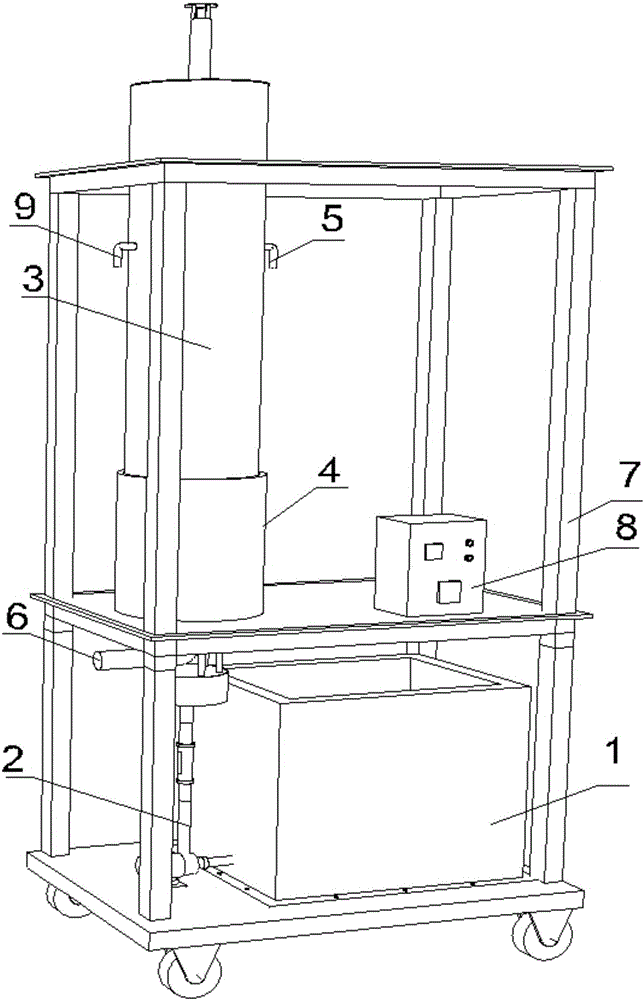

Vehicular underground water carbon tetrachloride treatment equipment and water purifying method thereof

A carbon tetrachloride and groundwater technology, which is applied in the direction of contaminated groundwater/leachate treatment, water/sewage treatment equipment, water/sewage treatment, etc., can solve complex operation and maintenance, high cost of nanotechnology, and difficult natural environment conditions Damaged and other problems, to achieve the effect of good treatment, small footprint, easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

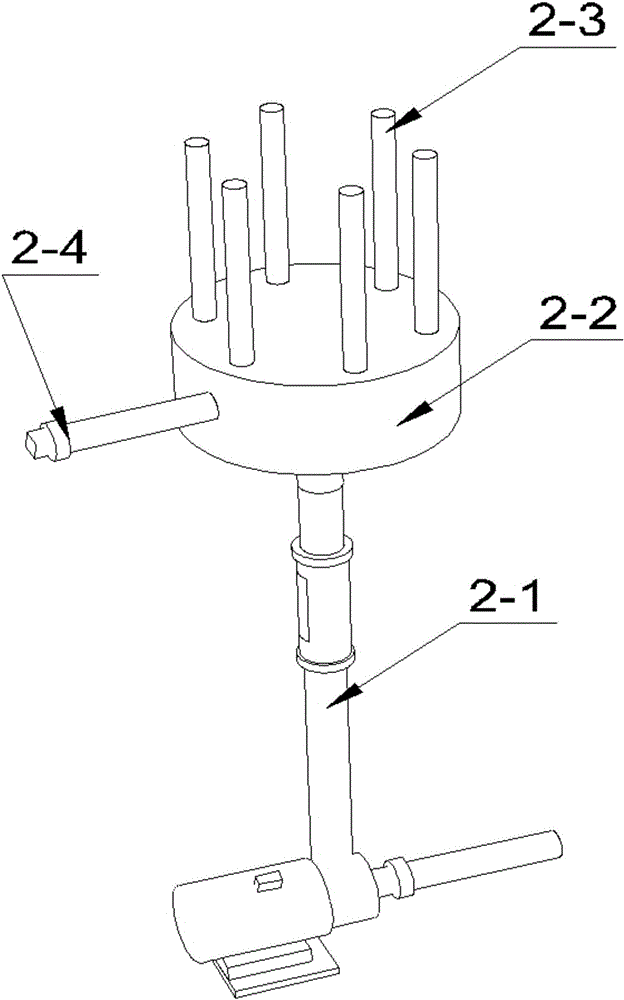

[0067] Manufacture the spoiler vane 3-1-2 of the present invention according to the following steps, and in parts by weight:

[0068] Step 1. Add 500 parts of ultrapure water with a conductivity of 0.001μS / cm into the reactor, start the stirrer in the reactor at a speed of 100rpm, and start the heating pump to raise the temperature in the reactor to 30°C; add in sequence 5 parts of ethyl dodecanoate, 1 part of ethyl nitrate, 3 parts of ethyl n-heptanoate, stir until completely dissolved, adjust the pH value to 6.5, adjust the speed of the agitator to 20rpm, and the temperature is 40°C, the esterification reaction 3 hours;

[0069] Step 2, take 5 parts of ethyl oleate, 6 parts of diethyl oxalate and pulverize, the particle size of the powder is 300 mesh; add 12 parts of nano-level palladium borate and mix evenly, spread it in the tray, the thickness of the laying is 50mm, use 15 minutes of α-ray irradiation with a dose of 1.0kGy and an energy of 1.0MeV;

[0070] The third ste...

Embodiment 2

[0074] Manufacture the spoiler vane 3-1-2 of the present invention according to the following steps, and in parts by weight:

[0075] Step 1. Add 850 parts of ultra-pure water with a conductivity of 0.02μS / cm into the reactor, start the stirrer in the reactor at a speed of 150rpm, start the heating pump to raise the temperature in the reactor to 70°C; add in sequence 20 parts of ethyl dodecanoate, 10 parts of ethyl nitrate, 10 parts of ethyl n-heptanoate, stir until completely dissolved, adjust the pH value to 8.9, adjust the speed of the agitator to 50rpm, and the temperature is 45°C, the esterification reaction 8 hours;

[0076] Step 2, take 20 parts of ethyl oleate, 9 parts of diethyl oxalate and pulverize, the particle size of the powder is 450 mesh; add 25 parts of nano-level palladium borate and mix evenly, spread it on the tray, the thickness of the laying is 100mm, use 45 minutes of α-ray irradiation with a dose of 5.5kGy and an energy of 5.5MeV;

[0077] The third s...

Embodiment 3

[0082] Manufacture the spoiler vane 3-1-2 of the present invention according to the following steps, and in parts by weight:

[0083] Step 1. Add 580 parts of ultrapure water with a conductivity of 0.00102μS / cm into the reactor, start the stirrer in the reactor at a speed of 145rpm, and start the heating pump to raise the temperature in the reactor to 46°C; add in order 16 parts of ethyl dodecanoate, 8 parts of ethyl nitrate, 7 parts of ethyl n-heptanoate, stir until completely dissolved, adjust the pH value to 6.589, adjust the speed of the agitator to 43rpm, and the temperature is 41°C, the esterification reaction 3.8 hours;

[0084] Step 2, take 5.20 parts of ethyl oleate, 6.9 parts of diethyl oxalate and pulverize, the particle size of the powder is 398 mesh; add 12.25 parts of nano-scale palladium borate and mix evenly, spread it on the tray, the thickness of the spread is 87mm, use 15.45 minutes of α-ray irradiation with a dose of 1.55kGy and an energy of 1.45MeV;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com