Single-component shunt-stabilized high-strength epoxy encapsulated resin adhesive and preparation method thereof

A technology of resin adhesive and epoxy resin, applied in the direction of epoxy resin glue, adhesive, adhesive additive, etc., can solve the problems of low strength, flying glue, waste of materials and labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

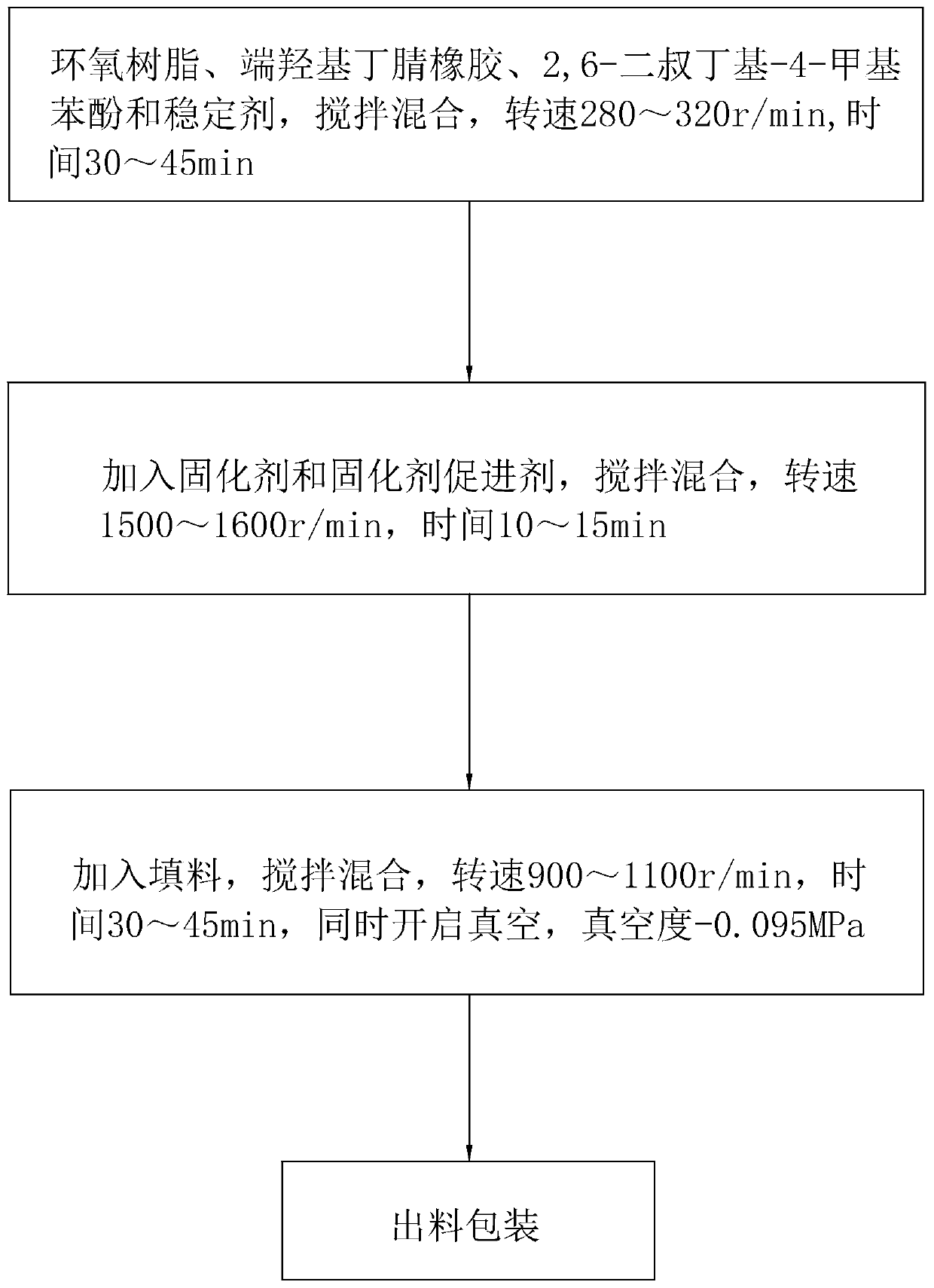

[0044] Example 1: A single-component rheologically stable high-strength epoxy encapsulating resin adhesive, each component and its corresponding parts by weight are shown in Table 1, and were prepared through the following steps:

[0045] Step 1, adding epoxy resin, toughening agent, 2,6-di-tert-butyl-4-methylphenol and stabilizer in corresponding parts by weight into the stirring tank, and dispersing for 30min at a speed of 300r / min;

[0046] Step 2, put the curing agent and curing accelerator into the stirring tank in step 1, and disperse at a high speed of 1500r / min for 10min;

[0047] Step 3: Put the filler into the stirred tank, disperse for 30 minutes at a speed of 1000r / min, and turn on the vacuum at the same time, the vacuum degree is -0.095MPa;

[0048] Step 4, discharging and packaging.

[0049] Among them, the epoxy resin adopts bisphenol A glycidyl ether with an epoxy equivalent of 180g / eq, the toughening agent adopts hydroxyl-terminated nitrile rubber with a numb...

Embodiment 2-10

[0050] Example 2-10: A one-component rheologically stable high-strength epoxy encapsulating resin adhesive, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1 .

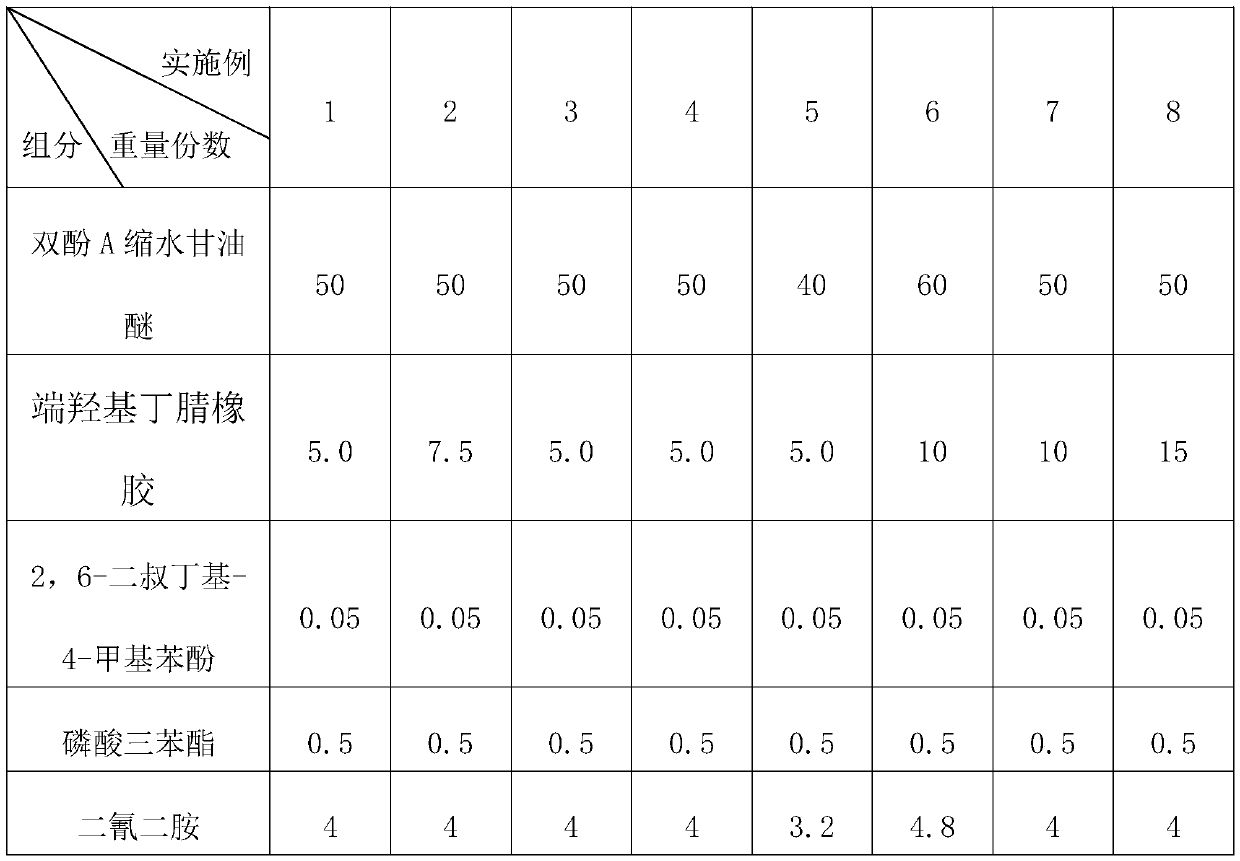

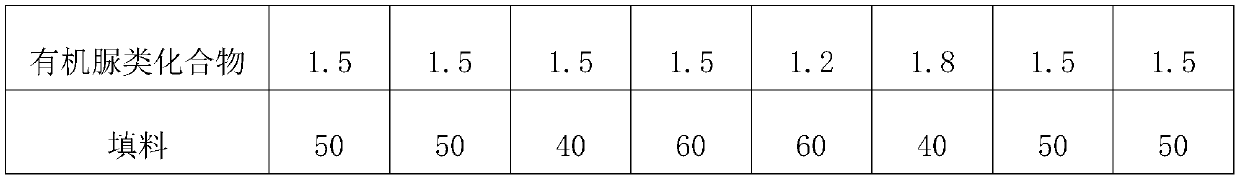

[0051] Each component and parts by weight thereof in table 1 embodiment 1-10

[0052]

[0053]

Embodiment 9

[0054]Example 9: A one-component rheologically stable high-strength epoxy encapsulating resin adhesive, the difference from Example 1 is that the filler uses glass fiber and carbon fiber and the ratio between the two is 1:1 , glass fiber by weight percentage is: aspect ratio (1:1) 10%; aspect ratio (10:1) 60%; aspect ratio (20:1) 30%; carbon fiber by weight percentage is: aspect ratio (1:1) 20%; aspect ratio (10:1) 50%; aspect ratio (20:1) 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com