Low-volatility environment-friendly pickling-free soldering flux solution and preparation method and application thereof

A low-volatility, pickling-free technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high saturated vapor pressure, high risk, low flash point, etc., achieve low saturated vapor pressure and wide application range , The effect of high boiling point of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Each embodiment of the present invention and the flux solution preparation method of comparative example are similar, and concrete steps are:

[0030] (1) triethyl borate and ethanol are mixed with triethyl borate ethanol solution, or trimethyl borate and methanol are mixed with trimethyl borate methanol solution;

[0031] (2) add water to triethyl borate ethanol solution, or add water to trimethyl borate methanol solution;

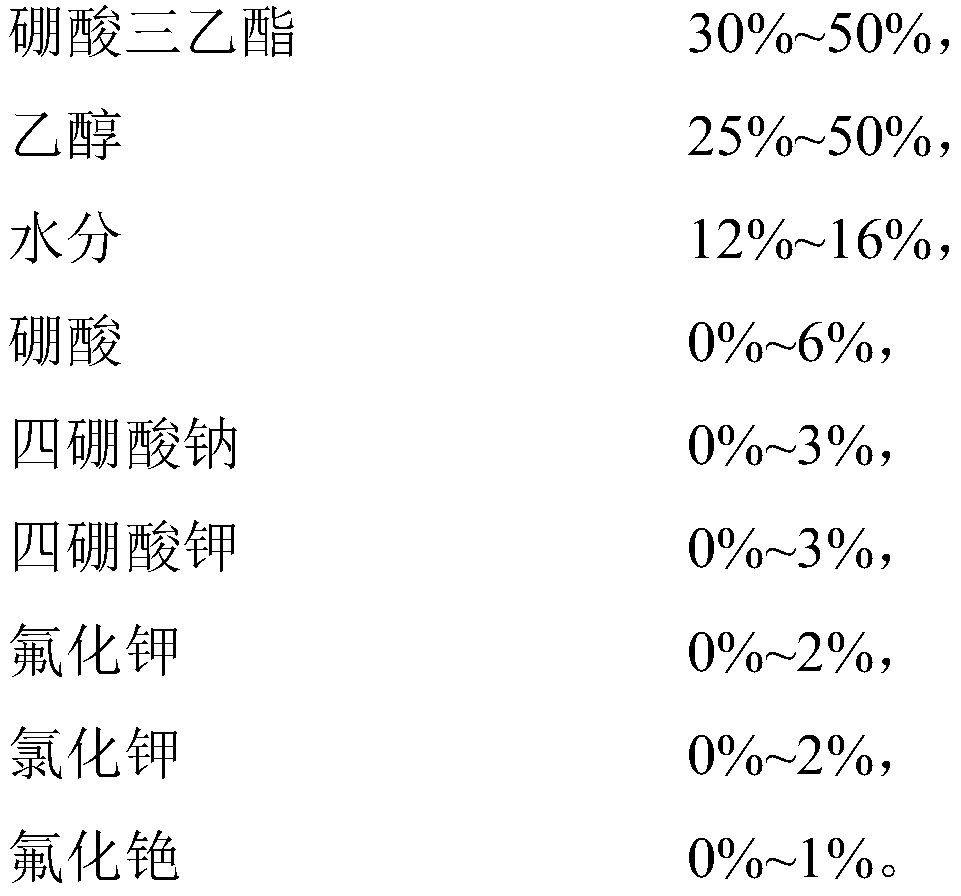

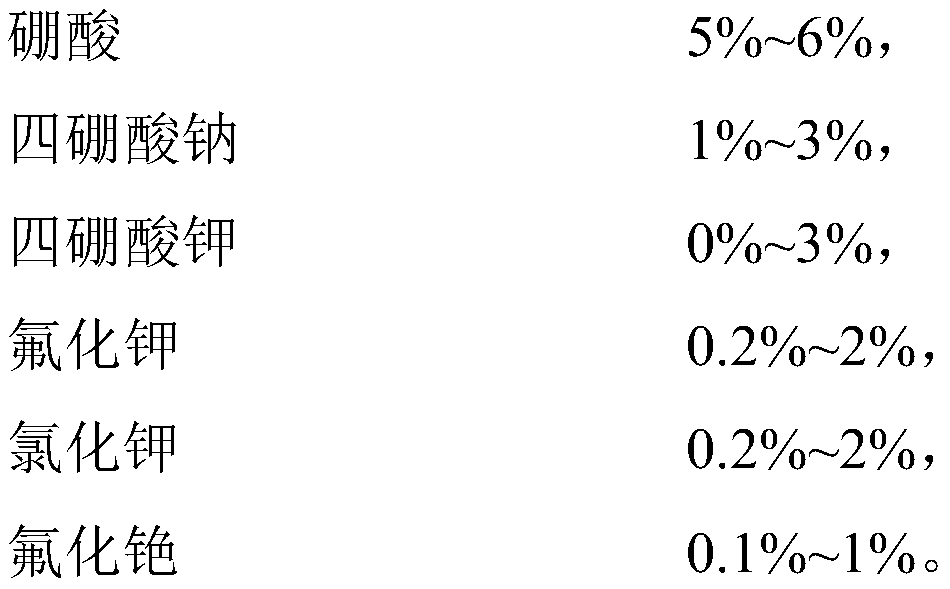

[0032] (3) Selectively add boric acid, sodium tetraborate, potassium tetraborate, potassium fluoride, potassium chloride and cesium fluoride as active elements to the mixed solution obtained in step (2) and dissolve to obtain a flux solution.

[0033] In the brazing test process of each embodiment of the present invention and the comparative example, except that the flux solution is different, other conditions (such as the amount of flux, the amount of solder, etc.) are the same.

Embodiment 1

[0035] Low-volatility pickling-free flux solution, according to the mass ratio of triethyl borate 30%, ethanol 47%, water 14%, boric acid 6%, sodium tetraborate 2%, potassium fluoride 0.5%, potassium chloride 0.5% . According to GB / T11363-2008 "Brazed Joint Strength Test Method", T2 red copper plate and H62 brass plate were used as the test base material, and the commercially available B-Cu93P solder was used as the test solder. Compared with that, after using the low-volatility pickling-free flux solution of this embodiment, the effective brazing area is increased by 15% and 16.5% respectively.

Embodiment 2

[0037] Low-volatility pickling-free flux solution, according to the mass ratio of triethyl borate 45%, ethanol 32%, water 14%, boric acid 6%, sodium tetraborate 1%, potassium tetraborate 1%, potassium fluoride 0.8% , Cesium fluoride 0.2%. According to GB / T11363-2008 "Brazed Joint Strength Test Method", T2 red copper plate and H62 brass plate were used as the test base material, and the commercially available B-Cu93P solder was used as the test solder. Compared with that, after using the low-volatility pickling-free flux solution of this embodiment, the effective brazing area is increased by 17.5% and 18% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com