Industrial water saving agent and preparation method therefor

An industrial, hydrophobic agent technology, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of high equipment investment, poor convenience, high operating energy consumption, and achieve the effect of safe operation, convenient recovery and good barrier effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

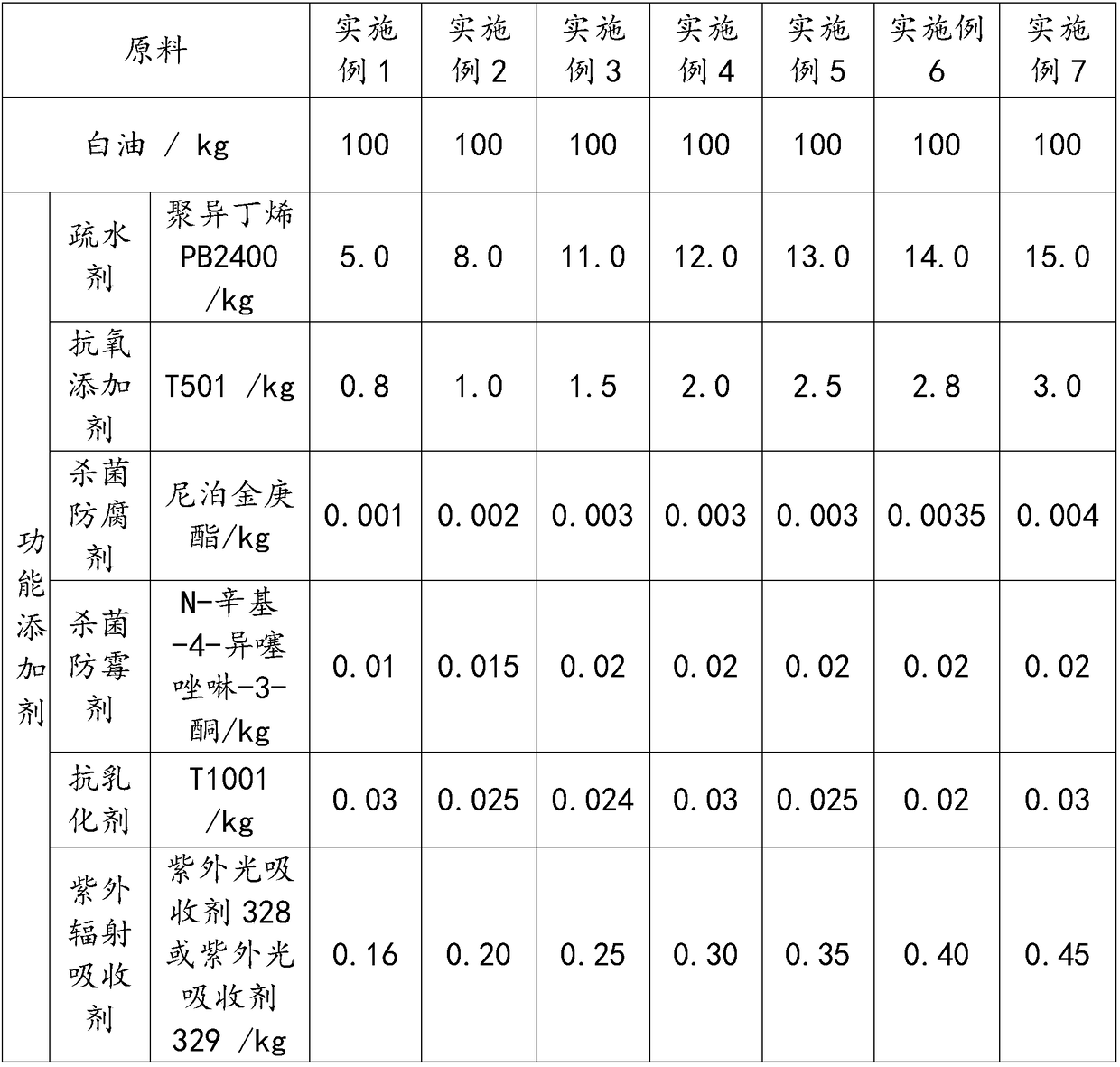

Embodiment 1

[0031] The raw materials are 100kg of white oil and 6.001kg of functional additives, wherein the 6.001kg of functional additives include: 5.0kg of hydrophobic agent, 0.8kg of antioxidant additive, 0.001kg of bactericidal preservative, 0.01kg of bactericidal and antifungal agent, 0.03kg of anti-emulsifier and ultraviolet Radiation absorber 0.16kg. In this embodiment, the embodiment is preferred, the hydrophobic agent is polyisobutylene P2400; the antioxidant additive is hindered phenolic antioxidant: T501; the bactericidal preservative is heptylparaben; The mold agent is N-octyl-4-isothiazolin-3-one; the anti-emulsifier is T1001; the ultraviolet radiation absorber is a benzotriazole ultraviolet radiation absorber: ultraviolet light absorber 328 or UV absorber 329.

[0032] The preparation steps are: (1) take 90kg of white oil in the raw material and pump it into the kettle, preheat it to 40-60°C; (2) heat the remaining 10Kg of white oil to 80-90°C, add a hydrophobic agent (pol...

Embodiment 2

[0034] The raw materials are 100kg of white oil and 9.242kg of functional additives, wherein the 9.242kg of functional additives include: 8.0kg of hydrophobic agent, 1.0kg of antioxidant additive, 0.002kg of bactericidal preservative, 0.015kg of bactericidal and antifungal agent, 0.025kg of anti-emulsifier and ultraviolet Radiation absorber 0.20kg. In this embodiment, the embodiment is preferred, the hydrophobic agent is polyisobutylene P2400; the antioxidant additive is hindered phenolic antioxidant: T501; the bactericidal preservative is heptylparaben; The mold agent is N-octyl-4-isothiazolin-3-one; the anti-emulsifier is T1001; the ultraviolet radiation absorber is a benzotriazole ultraviolet radiation absorber: ultraviolet light absorber 328 or UV absorber 329.

[0035]The preparation steps are: (1) take 80kg of white oil in the raw material and pump it into the kettle, and preheat it to 40-60°C; (2) heat the remaining 20kg of white oil to 80-90°C, add a hydrophobic Isob...

Embodiment 3

[0037] The raw materials are 100kg of white oil and 12.793kg of functional additives, wherein the 12.793kg of functional additives include: 11.0kg of hydrophobic agent, 1.5kg of antioxidant additive, 0.003kg of bactericidal preservative, 0.02kg of bactericidal and antifungal agent, 0.02kg of anti-emulsifier and ultraviolet Radiation absorber 0.25kg. In this embodiment, the embodiment is preferred, the hydrophobic agent is polyisobutylene P2400; the antioxidant additive is hindered phenolic antioxidant: T501; the bactericidal preservative is heptylparaben; The mold agent is N-octyl-4-isothiazolin-3-one; the anti-emulsifier is T1001; the ultraviolet radiation absorber is a benzotriazole ultraviolet radiation absorber: ultraviolet light absorber 328 or UV absorber 329.

[0038] The preparation steps are: (1) take 60kg of white oil in the raw material and pump it into the kettle, and preheat it to 40-60°C; (2) heat the remaining 40kg of white oil to 80-90°C, add a hydrophobic age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com