High-temperature antioxidant heat storage aluminum alloy

A high-temperature anti-oxidation and aluminum alloy technology, which is applied in the field of aluminum alloys, can solve the problems of high-temperature oxidation of heat-storing aluminum alloys, achieve good thermal stability, improve high-temperature oxidation resistance, and require less equipment and test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

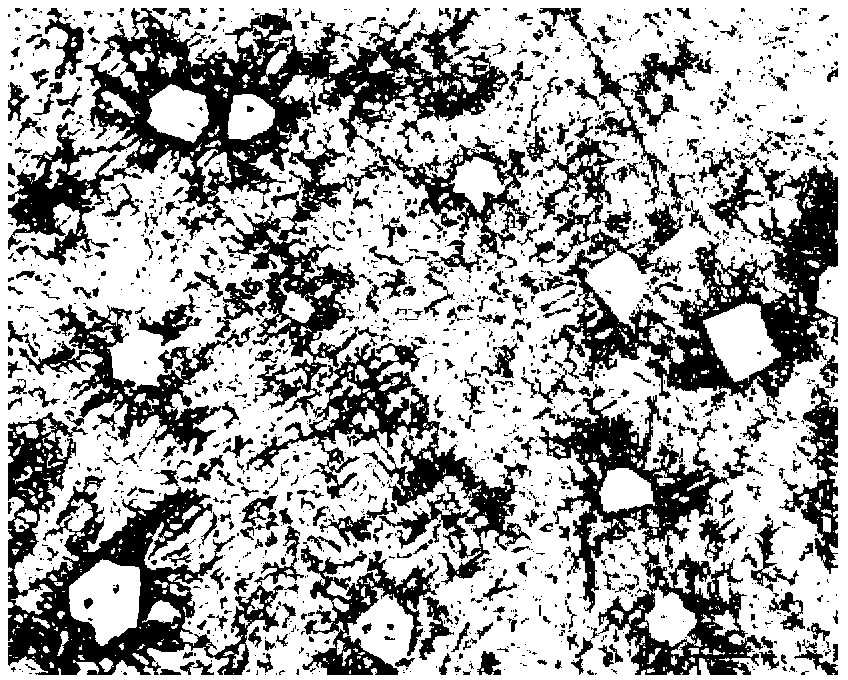

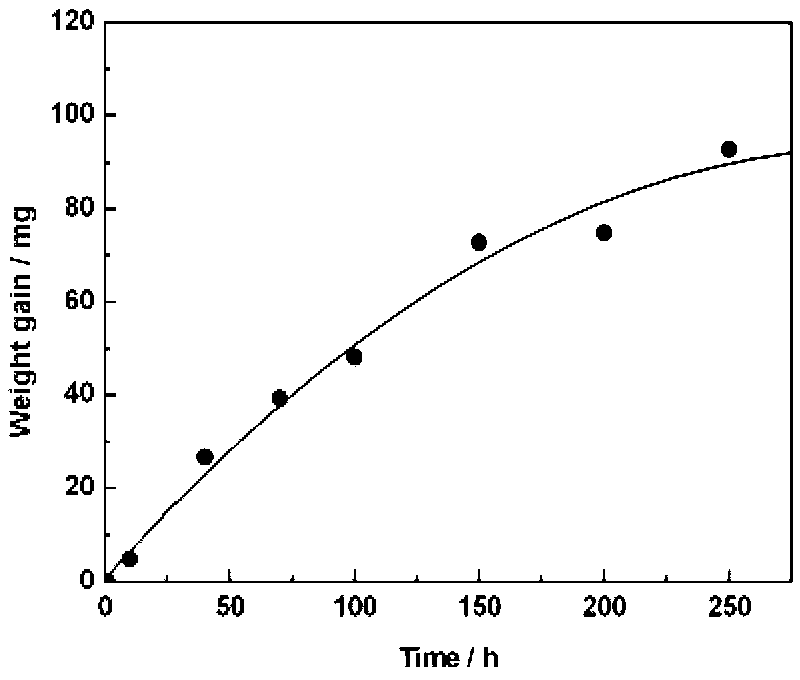

[0031] The chemical composition and content by weight percentage of the high-temperature anti-oxidation heat storage aluminum alloy of the present invention are: Si: 12.0%, Mg: 2.0%, Cu: 15.0%, and the balance is Al. Using SG 2 - 5-12 crucible furnaces for melting. The raw materials used mainly include Al-20%Si alloy, Al-50%Cu master alloy, industrial pure aluminum and pure magnesium. When smelting, first add Al-20%Si alloy, pure Al and Al-50%Cu alloy, raise the temperature to 750°C, after the melting is complete, cool down to 690°C, stir slightly, and press in pure Mg with a pressure spoon. Incubate at 720°C for 10 minutes. Stir the alloy liquid again, and use a metal mold to cast it into a cylindrical rod-shaped sample with a diameter of 30 mm and a length of 100 mm. its coagulated tissue see figure 1 . Its phase transition latent heat value is 509.4μV·s / mg, and the phase transition temperature range is 507.1-556.5°C.

Embodiment 2

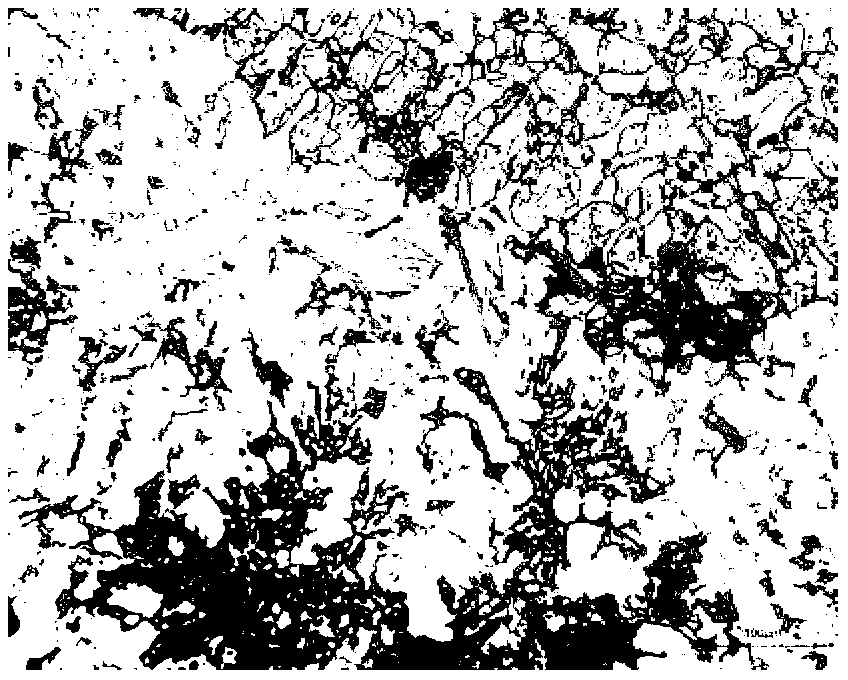

[0033] The chemical composition and content by weight percentage of the high-temperature anti-oxidation heat storage aluminum alloy of the present invention are: Si: 12.0%, Mg: 2.0%, Cu: 15.0%, RE: 0.1%, and the balance is Al. Using SG 2 - 5-12 crucible furnaces for melting. The raw materials used mainly include Al-20%Si alloy, Al-50%Cu master alloy, Al-10%RE master alloy, industrial pure aluminum and pure magnesium. When smelting, first add Al-20%Si alloy, pure Al and Al-50%Cu alloy, raise the temperature to 750°C, after the melting is complete, cool down to 690°C, stir slightly, and press in pure Mg with a pressure spoon. After the Mg is melted, raise the temperature to 750°C, let stand for 5 minutes, and stir evenly. Then, add the industrial Al-10%RE master alloy, stir evenly, and keep it at 720°C for 10min. Stir the alloy liquid again, and use a metal mold to cast it into a cylindrical rod-shaped sample with a diameter of 30 mm and a length of 100 mm. its coagulated ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com