High-frequency FeSiAl alloy powder and preparation method thereof

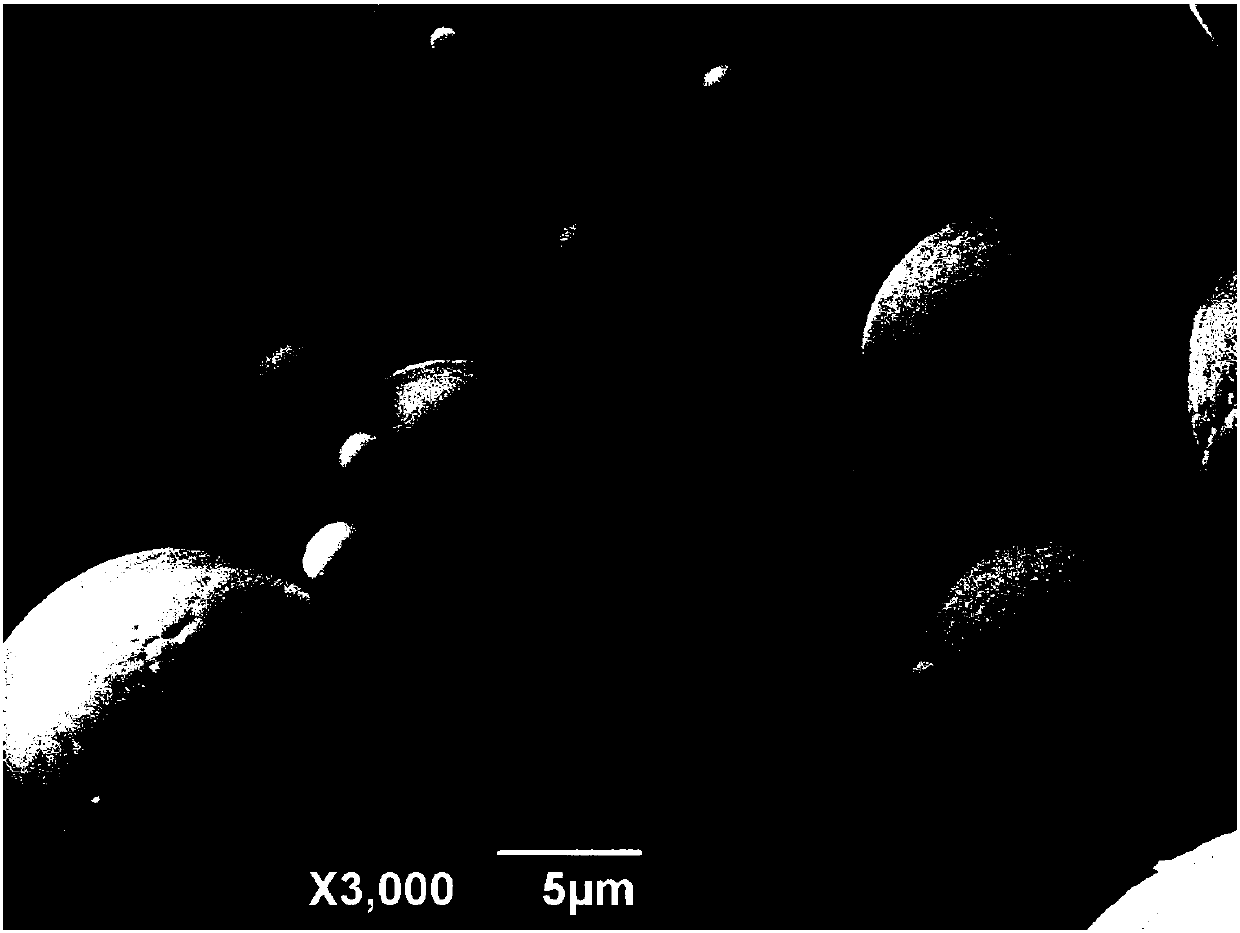

An alloy powder and high-frequency technology is applied in the field of high-frequency FeSiAl alloy powder and its preparation, which can solve the problems of difficult compaction of magnetic powder cores, easy piercing of insulating coating layers, easy occurrence of segregation, etc. Improve and simplify the smelting process, the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

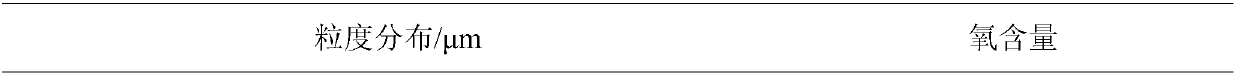

Examples

Embodiment 1

[0035] The preparation method of high-frequency FeSiAl alloy powder of the present invention, this method comprises the following specific steps:

[0036] Step S101, batching process: according to the batch weight and proportion of the charge, the raw materials are weighed and batched. The weight percentage of each raw material is: rod-shaped polished iron 84.55%, massive metal silicon 9.60%, pure aluminum ingot 5.85%; rod-shaped polished iron The brand name of Taiyuan Iron and Steel Co., Ltd. is YT01, with iron content of 99.9%, of which manganese content is 0.02%; the brand name of bulk metal silicon is 2202, silicon content is 99.7%, calcium content is 0.02%; %, of which copper content is 0.005%;

[0037]Step S102, smelting process: Put the prepared raw materials into the intermediate frequency furnace, and adopt vacuum melting: a) The material distribution method is: the rod-shaped polished iron of the furnace charge is placed against the furnace wall of the intermediate f...

Embodiment 2

[0049] The preparation method of high-frequency FeSiAl alloy powder of the present invention, this method comprises the following specific steps:

[0050] Step S101, batching process: according to the batch weight and proportion of the charge, the raw materials are weighed and batched. The weight percentage of each raw material is: rod-shaped polished iron 84.65%, massive metal silicon 9.60%, pure aluminum ingot 5.75%; rod-shaped polished iron The brand of Taiyuan Iron and Steel Co., Ltd. is YT01, with iron content of 99.9%, of which manganese content is 0.03%; the brand of bulk metal silicon is 441, with silicon content of 99.2%, and calcium content of 0.08%; %, of which copper content is 0.005%;

[0051] Step S102, smelting process: Put the prepared raw materials into the intermediate frequency furnace, and adopt vacuum melting: a) The material distribution method is: the rod-shaped polished iron of the furnace charge is placed against the furnace wall of the intermediate fr...

Embodiment 3

[0062] The preparation method of high-frequency FeSiAl alloy powder of the present invention, this method comprises the following specific steps:

[0063] Step S101, batching process: according to the batch weight and proportion of the furnace charge, the raw materials are weighed and batched. The weight percentage of each raw material is: rod-shaped polished iron 84.40%, massive metal silicon 9.60%, pure aluminum ingot 6.0%; rod-shaped polished iron The brand name of Taiyuan Iron and Steel Co., Ltd. is YT01, with iron content of 99.9%, of which manganese content is 0.02%; the brand name of bulk metal silicon is 2202, silicon content is 99.7%, calcium content is 0.02%; %, of which copper content is 0.002%;

[0064] Step S102, smelting process: Put the prepared raw materials into the intermediate frequency furnace, and adopt vacuum melting: a) The material distribution method is: the rod-shaped polished iron of the furnace charge is placed against the furnace wall of the interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com