Energy-saving environment-protecting secondary lead multi-chamber metal smelting furnace and treatment method

A technology of energy saving, environmental protection and treatment method, applied in the field of metal smelting, can solve the problems of high content of valuable metals, ecological environment pollution, low vertical yield, etc., and achieves high recovery rate of valuable metals, high degree of automation and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

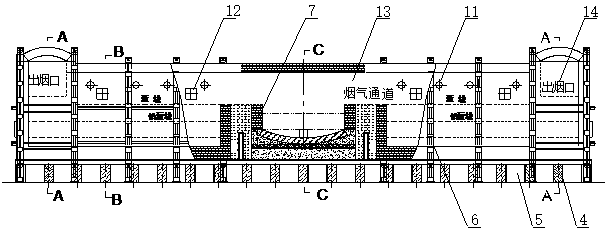

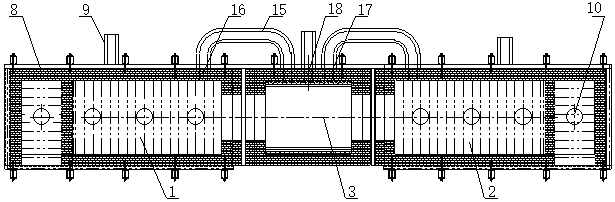

[0038] Embodiment 1: The present invention includes a metal melting furnace and a treatment method using a metal melting furnace.

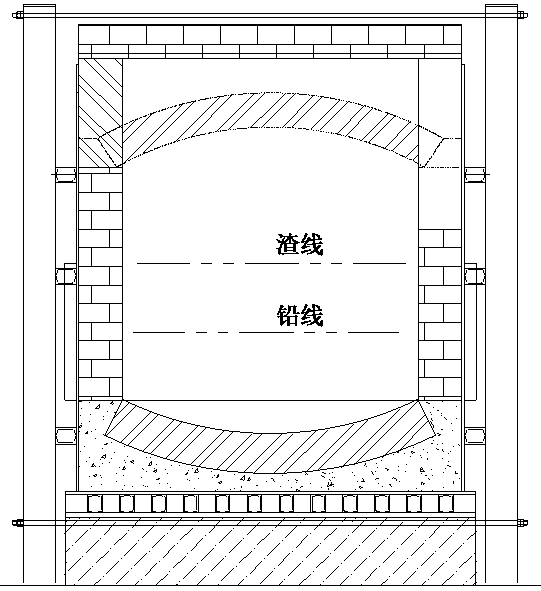

[0039] The smelting furnace comprises: a smelting furnace device, a gasification furnace 3, a furnace base 4, a furnace steel frame 6, a furnace masonry 7, a furnace shell 8, a flue gas passage 13, a smoke outlet 14, a liquid slag chute 15, a liquid slag Inlet 17, waste slag opening 18, flue gate 19 and flue 20; furnace shell 8 is installed on the furnace base 4, the smelting furnace device and gasification furnace 3 are connected as a whole, and there is a furnace steel frame 6 outside the furnace shell 8 to The furnace shell is tightened; the inner side of the furnace shell 8 is a refractory furnace masonry 7, and there is a flue gas channel 13 connected between the smelting furnace device and the gasification furnace 3; there is a liquid slag chute 15 between the smelting furnace device and the gasification furnace 3. The two ends of the slag c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com