Aluminum alloy smelting and impurity-removing method based on electromagnetic stirring

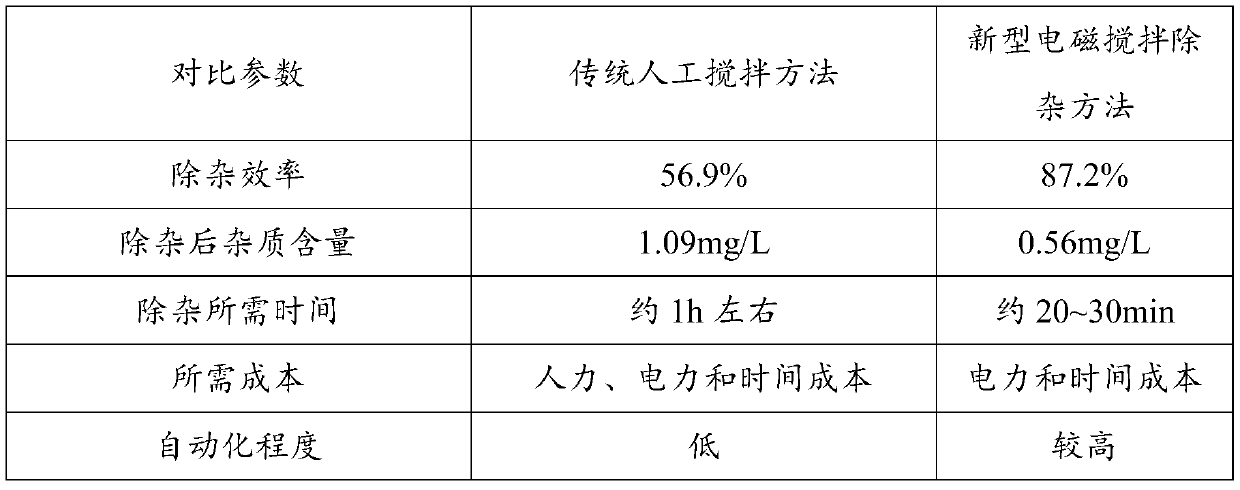

An electromagnetic stirring and aluminum alloy technology, which is applied in the field of alloy smelting, can solve the problems of low efficiency, time-consuming and laborious impurity removal, and increase the cost of production line failure rate, so as to achieve high purity, improve production efficiency, and automate and improve production. Effect of impurity removal efficiency and melt purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

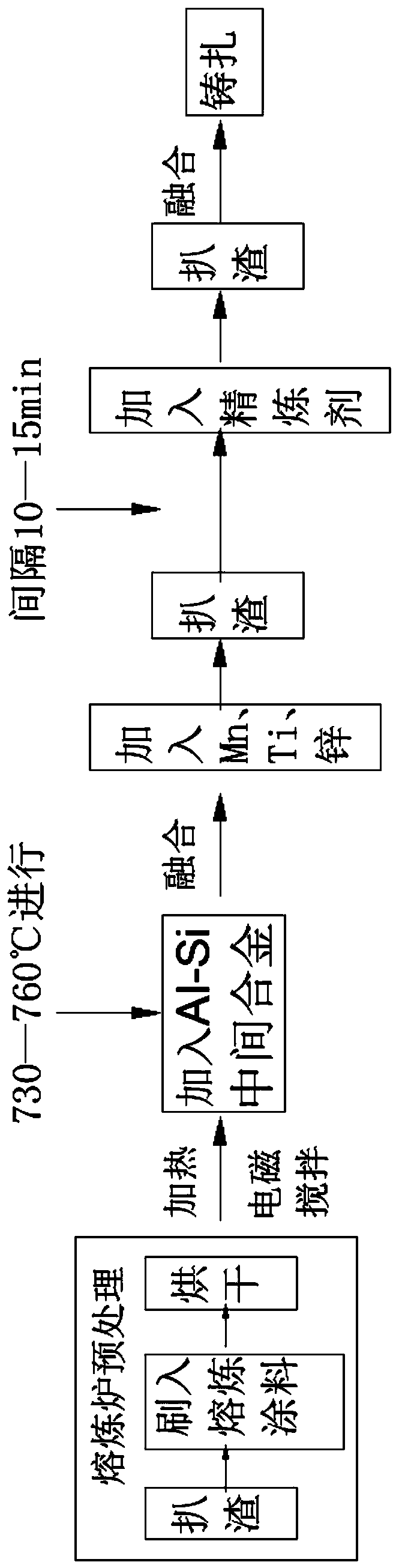

[0047] A method for melting and removing impurities of aluminum alloy based on electromagnetic stirring, comprising the following steps:

[0048] S1: Melting furnace pretreatment;

[0049] S2: adding high-purity aluminum with a purity of 99% or more to the pretreated smelting furnace;

[0050] S3: heating the melting furnace;

[0051] S4: adding Al-Si master alloy;

[0052] S5: fusion of high-purity aluminum and Al-Si master alloy;

[0053] S6: adding zinc, Mn agent, Ti agent and refining agent with a purity of 99% or more;

[0054] S7: Fusion of all metals in S5 and S6;

[0055] S8: transfer the aluminum alloy melt obtained in S7 to a launder for casting and rolling;

[0056] In the S3 process, the temperature of the melting furnace is set at 720-800°C, and electromagnetic stirring is used for fusion. The working parameters of the inductor (coil) are: sinusoidal alternating current (50Hz), apparent power 230KVA, frequency 4.5-5.5Hz , the working current is 200A, stirrin...

Embodiment 2

[0083] An aluminum alloy, which is produced based on the aluminum alloy smelting and impurity removal method described in Example 1.

[0084] Working principle: According to the composition requirements of aluminum alloy products, add pure aluminum, Al-Si master alloy and pure zinc, Mn agent and Ti agent into the melting furnace, and add them one by one in order. Turn on the resistance heating device of the smelting furnace and heat to 780°C to melt the alloy components into a uniform Al-Si-Zn intermediate aluminum alloy metal melt.

[0085] Keep the setting value of the smelting furnace at 780°C for heat preservation, and blow CCl into the aluminum intermediate metal melt through pure argon with a purity of 99.99% and a pressure of 0.4Mpa in the smelting furnace 4 Refining agent, at this time, when the melt temperature is 720-740°C, turn on the electromagnetic stirring device (installed power 70KW, 380V three-phase sinusoidal alternating current, 50Hz), and the working parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com