Device and method for removing impurity in uranium metal effectively

An impurity and metal technology, applied in the field of uranium metal purification, can solve the problems of no research, high impurity content, no refining and purification process, etc., and achieve the effects of high impurity removal efficiency, reduction of impurity content, and high utilization rate of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

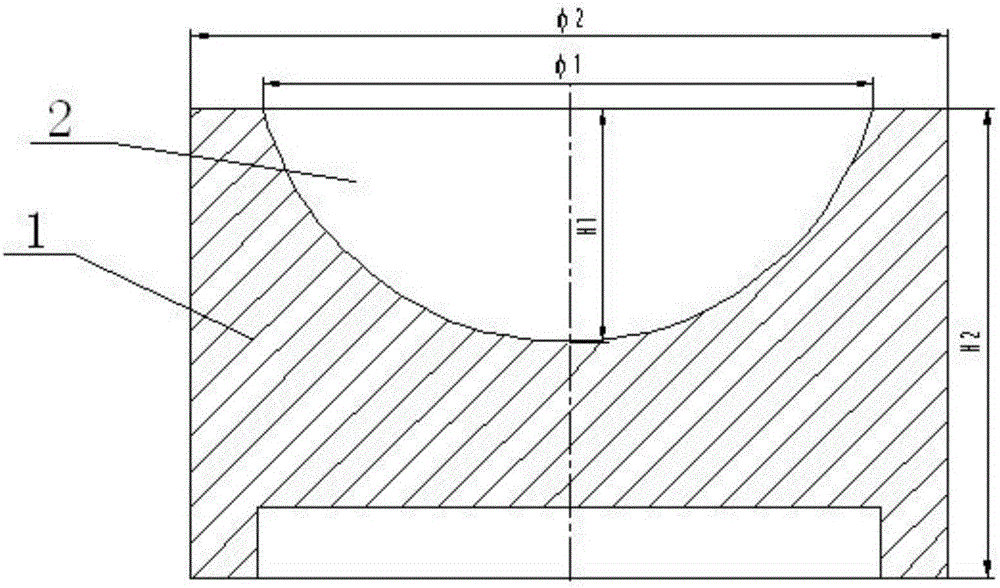

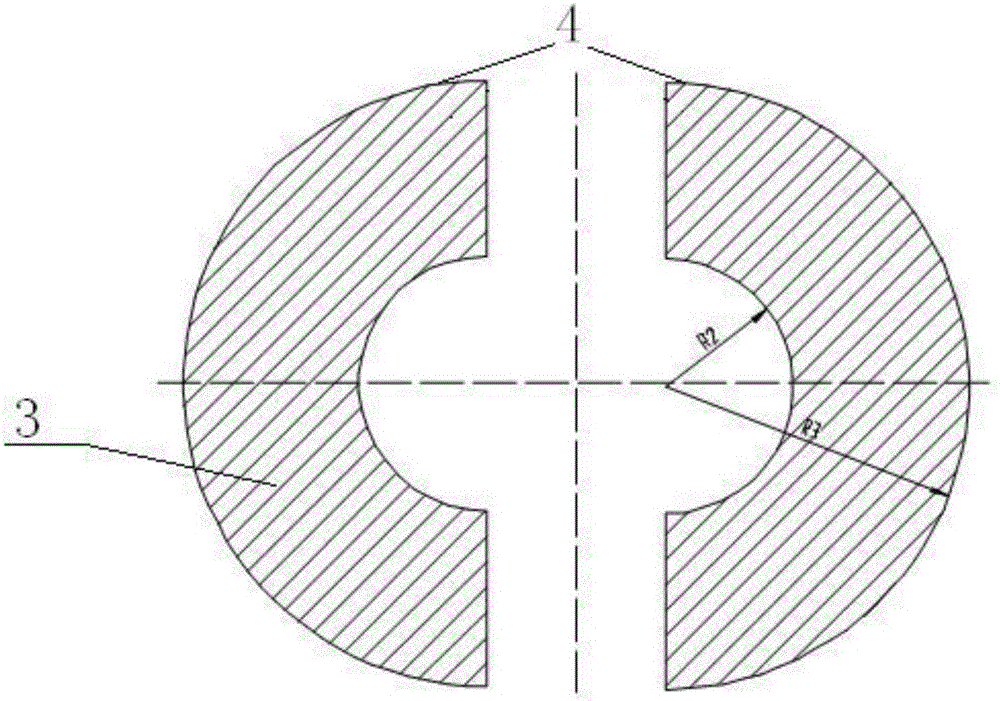

[0063] In the device of this example, the diameter of the melting chamber of the water-cooled copper crucible is 100mm and the outer diameter of the water-cooled copper crucible is 130mm, the depth of the melting chamber is 30mm, the inner surface roughness of the melting chamber is Ra 0.8, and the height of the water-cooled copper crucible is 70mm The outer circumference of the water-cooled copper crucible is provided with a graphite ring, which includes two graphite rings and each graphite ring is spliced by two fan-shaped graphite blocks. The thickness of a single graphite ring is 20mm, and the inner diameter of the graphite ring is 130mm. The outer diameter is 390mm, the graphite ring is 40mm higher than the upper edge of the crucible, the ash content of the graphite ring is not more than 0.08% and the porosity is not more than 22%.

[0064] Carry out smelting purification according to the following steps:

[0065] (1) Furnace loading: the raw material is uranium ingot p...

example 2

[0072] In the device of this example, the diameter of the melting chamber of the water-cooled copper crucible is 100mm and the outer diameter of the water-cooled copper crucible is 130mm, the depth of the melting chamber is 30mm, the inner surface roughness of the melting chamber is Ra 0.8, and the height of the water-cooled copper crucible is 70mm The outer circumference of the water-cooled copper crucible is provided with a graphite ring, which only includes a graphite ring and is spliced by four fan-shaped graphite blocks. The thickness of the graphite ring is 30mm, the inner diameter of the graphite ring is 130mm, and the outer diameter of the graphite ring is 650mm. The graphite ring is 30mm higher than the upper edge of the crucible, the ash content of the graphite ring is not more than 0.08% and the porosity is not more than 22%.

[0073] Follow these steps:

[0074] (1) Furnace loading: the raw material is uranium ingot pre-doped with 1000 μg / g impurity element Al, w...

example 3

[0081] In the device of this example, the diameter of the melting chamber of the water-cooled copper crucible is 160mm and the outer diameter of the water-cooled copper crucible is 200mm, the depth of the melting chamber is 40mm, the inner surface roughness of the melting chamber is Ra 0.8, and the height of the water-cooled copper crucible is 90mm The outer circumference of the water-cooled copper crucible is provided with a graphite ring, which only includes a graphite ring and is spliced by four fan-shaped graphite blocks. The thickness of the graphite ring is 20mm, the inner diameter of the graphite ring is 200mm, and the outer diameter of the graphite ring is 600mm. The graphite ring is 20mm higher than the upper edge of the crucible, the ash content of the graphite ring is not more than 0.08%, and the porosity is not more than 22%.

[0082] Follow these steps:

[0083] (1) Furnace loading: the raw material is uranium ingot pre-doped with 1000 μg / g impurity element Al, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com