Method for removing impurities from aluminum ash

A technology of aluminum ash slag and aluminum hydroxide, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of high material consumption and energy consumption, high impurity content, large pollution, etc., achieve high efficiency of impurity removal, prevent The effect of low corrosion requirements and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

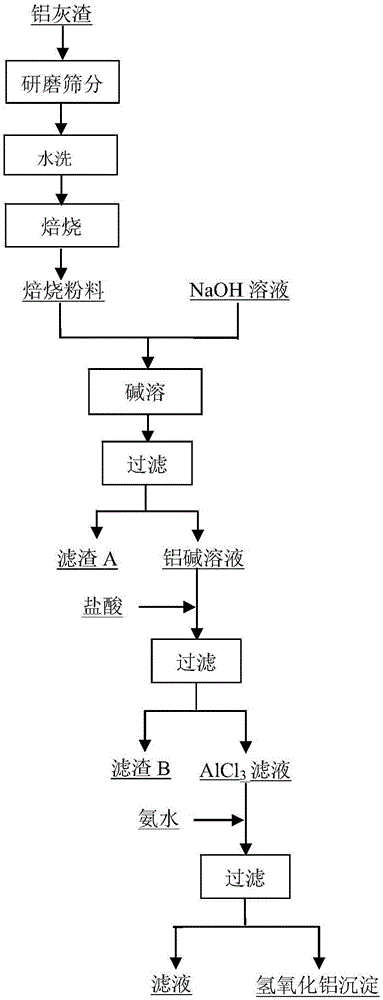

Image

Examples

Embodiment 1

[0024] Step (1): After grinding, sieving, washing (deionized water), the aluminum ash residue is roasted to obtain roasted powder with a certain particle size; wherein the screening condition is 20 mesh; the washing condition is: washing temperature 80 ℃, water washing time 7h; calcination conditions: calcination time 4h, calcination temperature 650℃.

[0025] Step (2): Add the calcined powder to the NaOH solution, heat and stir for a period of time, and perform solid-liquid separation through filtration to obtain an aluminum alkali solution; wherein the NaOH solution has a concentration of 40% by weight, a liquid-solid mass ratio of 4:1, and alkali-soluble Time 4h, alkali melting temperature 150℃.

[0026] Step (3): Add excess dilute hydrochloric acid to the aluminum alkali solution, observe the precipitation in the solution until the amount of precipitation does not change, and then perform solid-liquid separation by filtration to obtain AlCl 3 The filtrate; wherein the concentra...

Embodiment 2

[0029] Step (1): After grinding, sieving and washing (deionized water) the aluminum ash residue, roasting is performed to obtain roasted powder with a certain particle size; wherein the screening condition is 20 mesh; the washing condition is: washing temperature 90 ℃, water washing time 6h; calcination conditions: calcination time 3.5h, calcination temperature 700 ℃.

[0030] Step (2): Add the calcined powder to the NaOH solution, heat and stir for a period of time, and then perform solid-liquid separation by filtration to obtain an aluminum alkali solution; wherein the NaOH solution has a concentration of 40% by weight, a liquid-solid mass ratio of 5:1, and alkali-soluble Time 4h, alkali melting temperature 180℃.

[0031] Step (3): Add excess dilute hydrochloric acid to the aluminum alkali solution, observe the precipitation in the solution until the amount of precipitation does not change, and then perform solid-liquid separation by filtration to obtain AlCl 3 The filtrate; wher...

Embodiment 3

[0034] Step (1): After grinding, sieving and washing the aluminum ash (deionized water), roasting is performed to obtain roasted powder with a certain particle size; wherein the screening condition is 60 mesh; the washing condition is: washing temperature 100 ℃, water washing time 6h; calcination conditions: calcination time 3h, calcination temperature 750℃.

[0035] Step (2): Add the calcined powder to the NaOH solution, heat and stir for a period of time, and then perform solid-liquid separation by filtration to obtain an aluminum alkali solution; wherein the NaOH solution has a concentration of 35wt%, a liquid-solid mass ratio of 6:1, and alkali-soluble Time 3.5h, alkali melting temperature 210℃.

[0036] Step (3): Add excess dilute hydrochloric acid to the aluminum alkali solution, observe the precipitation in the solution until the amount of precipitation does not change, and then perform solid-liquid separation by filtration to obtain AlCl 3 The filtrate; wherein the concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com