Purification treatment method of wet-process phosphoric acid

A technology for wet-process phosphoric acid and purification treatment, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high cost of thermal phosphoric acid, serious environmental pollution, large phosphorus loss, etc. The effect of high efficiency and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A, according to the fluorine ion selective electrode method and the mass percent content of fluorine in phosphoric acid measured by the barium sulfate gravimetric method is 1.3% (F); the mass percent content of sulfur trioxide is: 3.2% (SO 3 ).

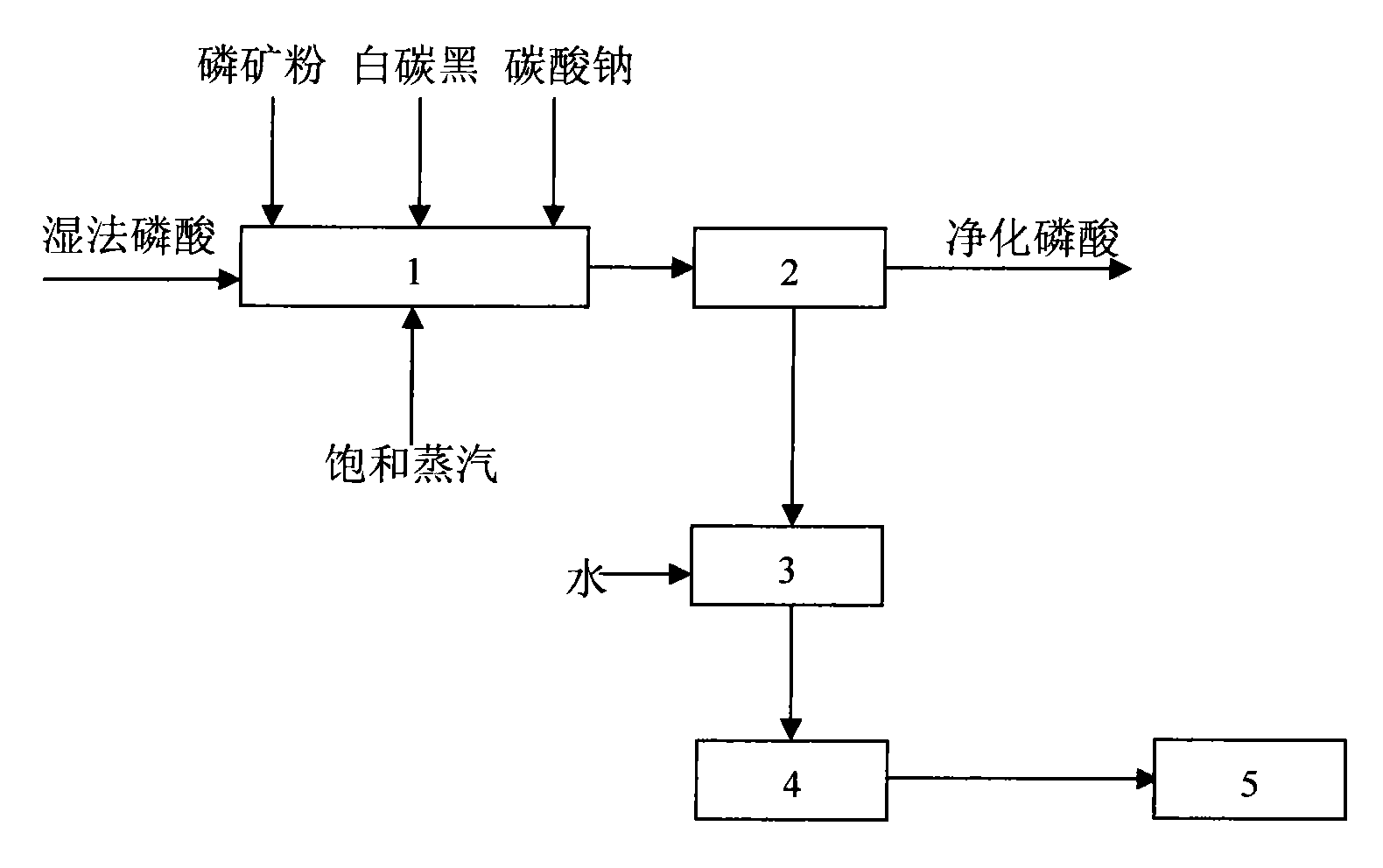

[0030] B, add 75 tons of wet process phosphoric acid in reaction tank 1. Add 615 kg of active silicon dioxide that meets the HG / T 3061-1999 standard, 1080 kg of sodium carbonate with a total alkali content ≥ 98.8%, and 3500 kg of P 2 o 5 ≥32% phosphate rock is ground into powder phosphate rock powder with a fineness of 200 or 230 or 250 or 270 or 300 or 325 mesh.

[0031] C. Feed saturated steam into reaction tank 1, heat the material to 65 or 67 or 69 or 70°C, and stir at constant temperature for 110 or 115 or 125 or 130 minutes to obtain a well-reacted material.

[0032] D. Send the reacted material into the tank 2 of the plate and frame filter press with the pump 4, and the filtrate after the press filtration is qualified...

Embodiment 2

[0035] A, according to the fluorine ion selective electrode method and the mass percent content of fluorine in phosphoric acid measured by the barium sulfate gravimetric method is 1.3% (F); the mass percent content of sulfur trioxide is: 3.2% (SO 3 ).

[0036] B, add 75 tons of wet process phosphoric acid in reaction tank 1. Add 615 kg of active silicon dioxide that meets the HG / T 3061-1999 standard, 1080 kg of sodium carbonate with a total alkali content ≥ 98.8%, and 3500 kg of P 2 o 5 ≥32% Phosphate rock powder ground into 200 or 235 or 245 or 260 or 313 or 323 mesh powder phosphate rock powder.

[0037] C. Feed saturated steam into reaction tank 1, heat the material to 66 or 68°C, and stir at constant temperature for 113 or 117 or 120 or 128 minutes to obtain a well-reacted material.

[0038] D. Send the reacted material into the tank 2 of the plate and frame filter press with the pump 4, and the filtrate after the press filtration is qualified purified wet-process phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com