Wheat impurity-removing device

A wheat and collecting device technology, which is applied in the directions of drying and preserving seeds, solid separation, and sieving, etc., can solve the problems of high labor intensity for farmers, economic losses of farmers, and large floor space, and achieves a wide range of use and reduces labor. Strength, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

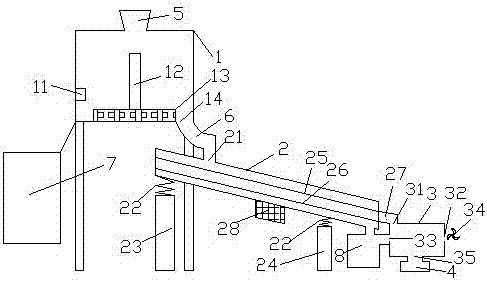

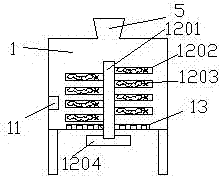

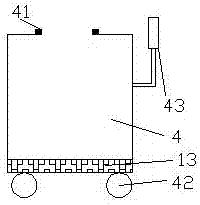

[0026] see figure 1 , the present embodiment relates to a wheat impurity removal device, comprising a drying chamber 1, a vibrating screening device 2, a winnowing mechanism 3 and a wheat collecting device 4, the drying chamber 1 is located above the vibrating screening device 2, and the wind Selecting mechanism 3 is positioned at the below of vibration screening device 2, and described wheat collecting device 4 is positioned at the below of described winnowing mechanism 3;

[0027] A feed hopper 5 is provided above the drying chamber 1, a humidity sensor 11 and a drying device 12 are provided inside the drying chamber 1, a pressure sensor 13 is provided at the bottom of the drying chamber 1, and a discharge port 14 of the drying chamber is provided. Communicate with the feeding port 21 of the vibratory screening device through the feed pipeline 6;

[0028] The two ends of described vibratory screening device 2 are respectively fixed on the first support 23 and the second sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com