Patents

Literature

67results about How to "Avoid manual processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

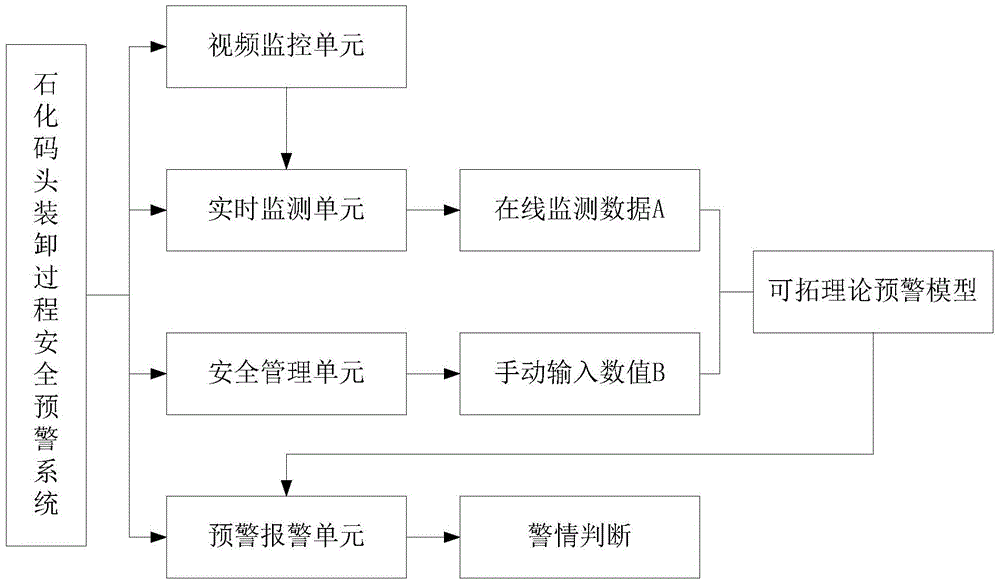

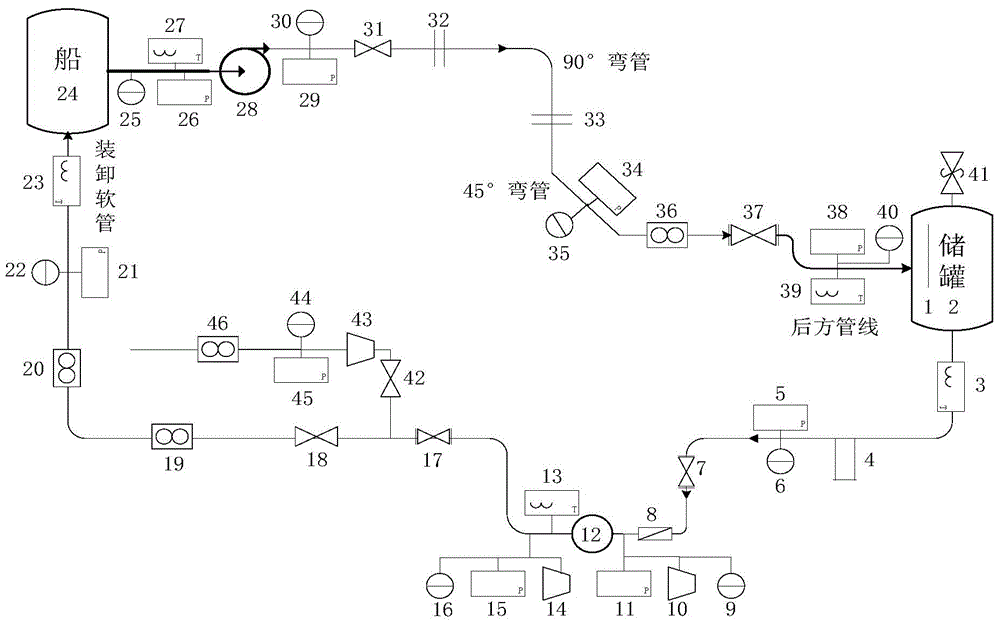

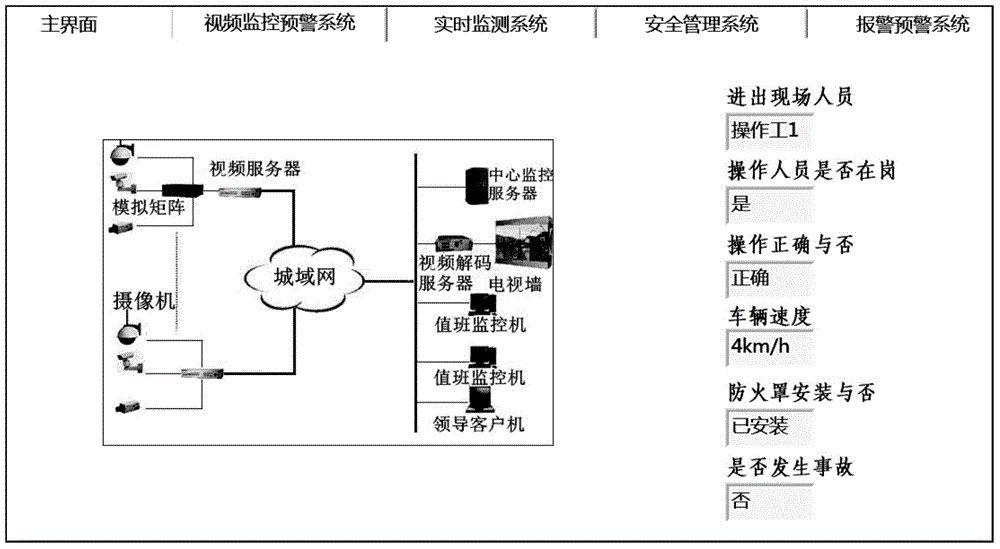

Petrochemical engineering wharf handling process safety early-warning system based on LabVIEW

InactiveCN104463425ARealize real-time monitoringRealize data queryPipeline systemsResourcesVideo monitoringPetrochemical

A petrochemical engineering wharf handling process safety early-warning system based on a LabVIEW comprises a video monitoring unit, a real-time monitoring unit, a safety management unit and an early-warning unit, wherein the real-time monitoring unit is especially used for monitoring parametric variation generated in liquid handling operation and comprises corresponding testing systems. The real-time monitoring unit collects signals of the concentration, temperature, pressure, flow and the like of liquid to be monitored and obtains related parameter values A, quantized values B of indexes in the safety management unit are manually input, and the parameter values A and the quantized values B are transmitted into a petrochemical engineering wharf handling process extension theory early-warning model developed based on a LabVIEW platform; when all the parameters meet settings, the early-warning model is triggered, the current state of the handling process is provided, and an early warning is given under abnormal or nonstandard conditions to inform related personnel to take pre-control measures. According to the system, the functions of on-line monitoring early warning, data query and visual display of the parameters of liquid in an oil pipeline can be achieved in the handling process.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

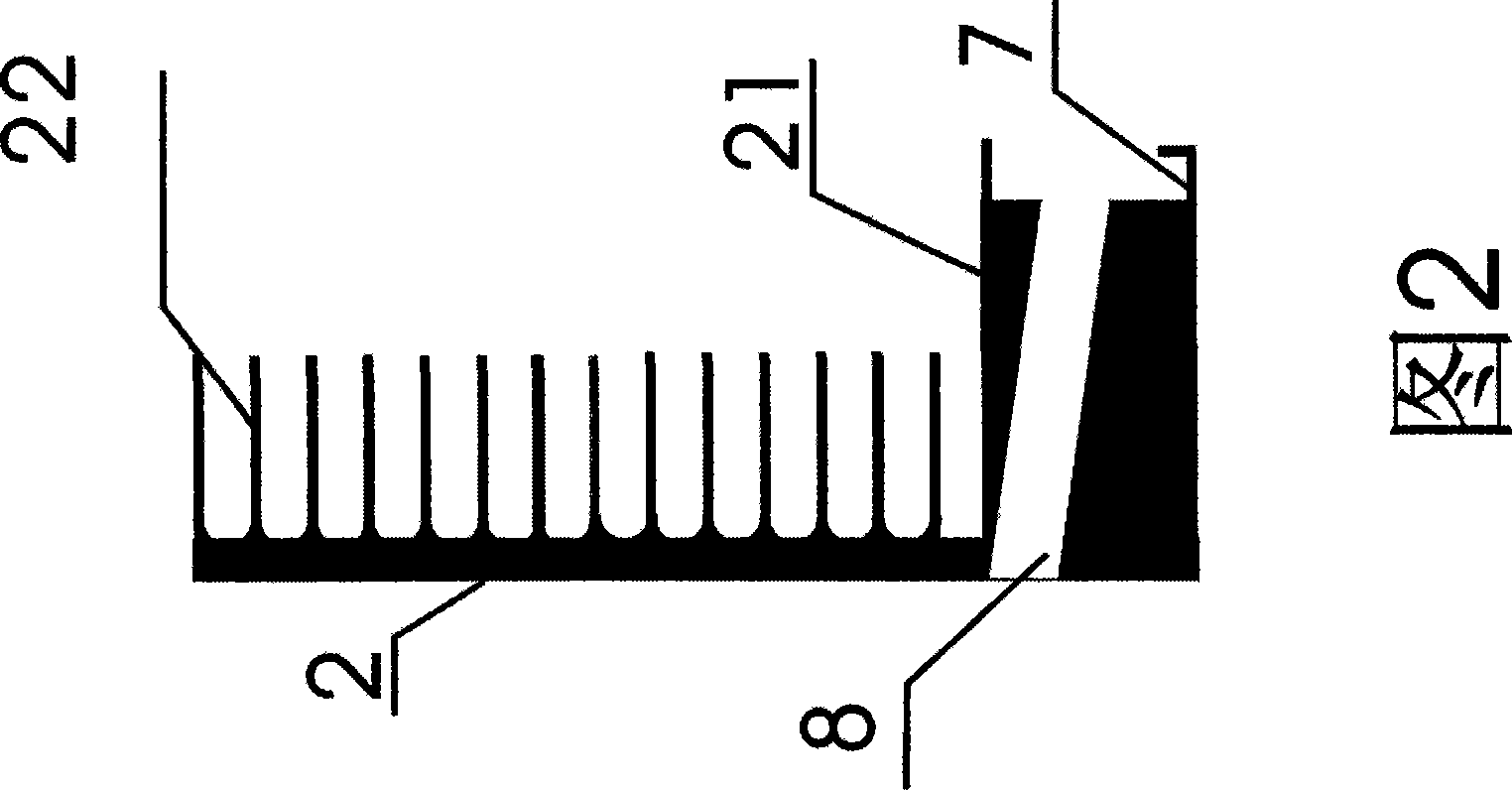

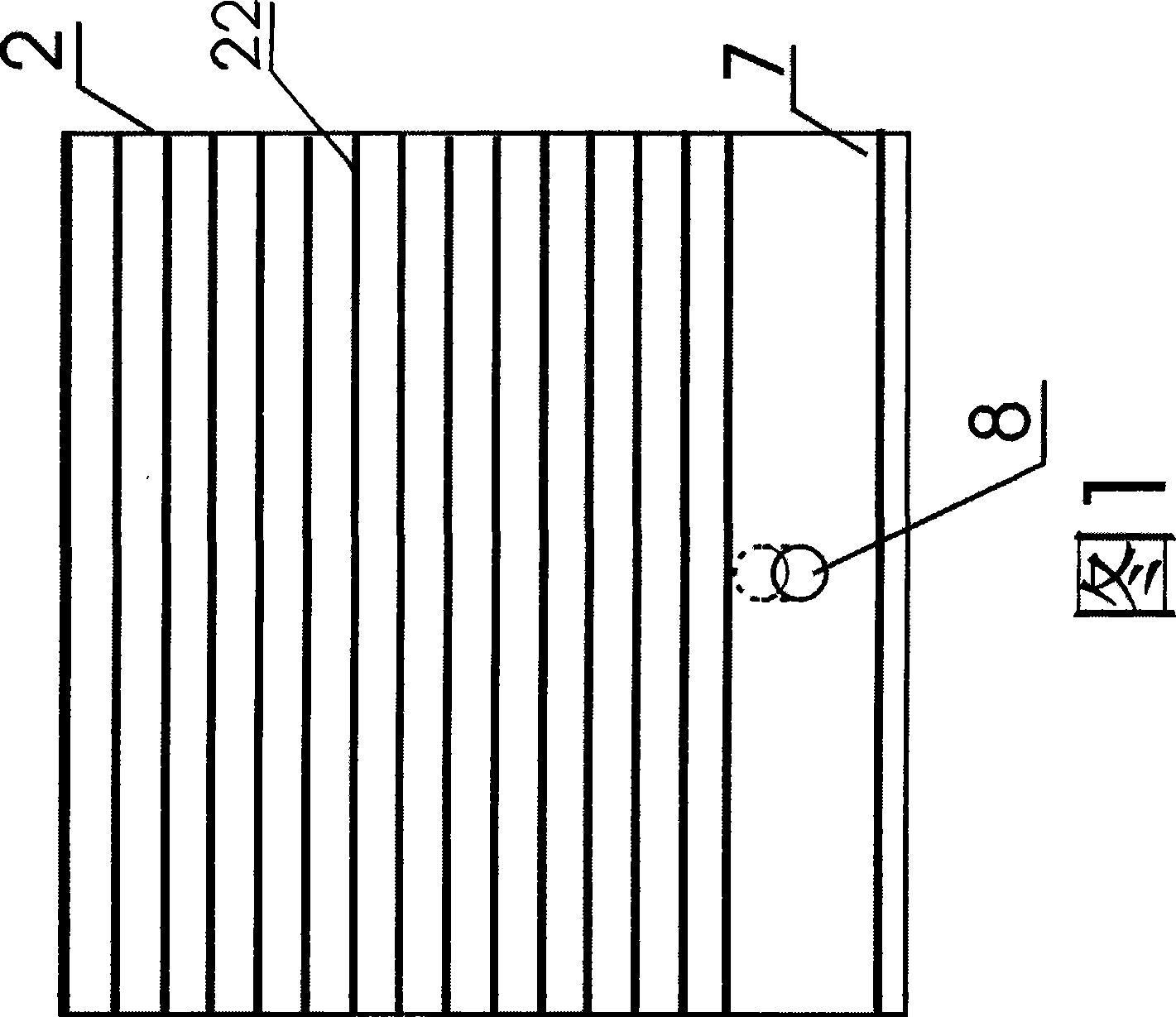

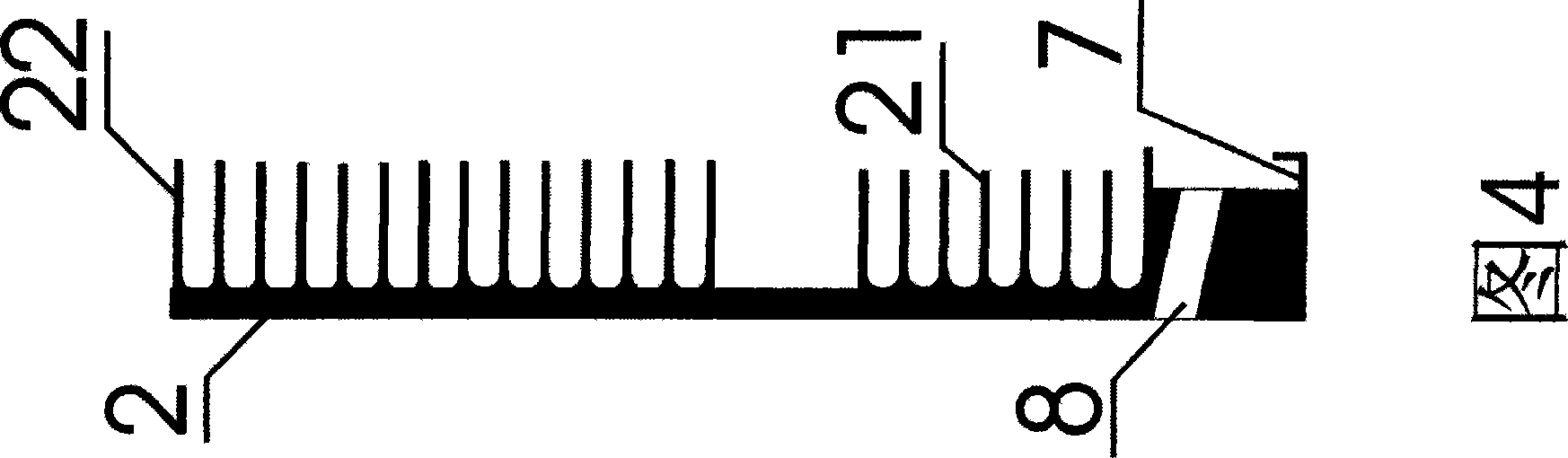

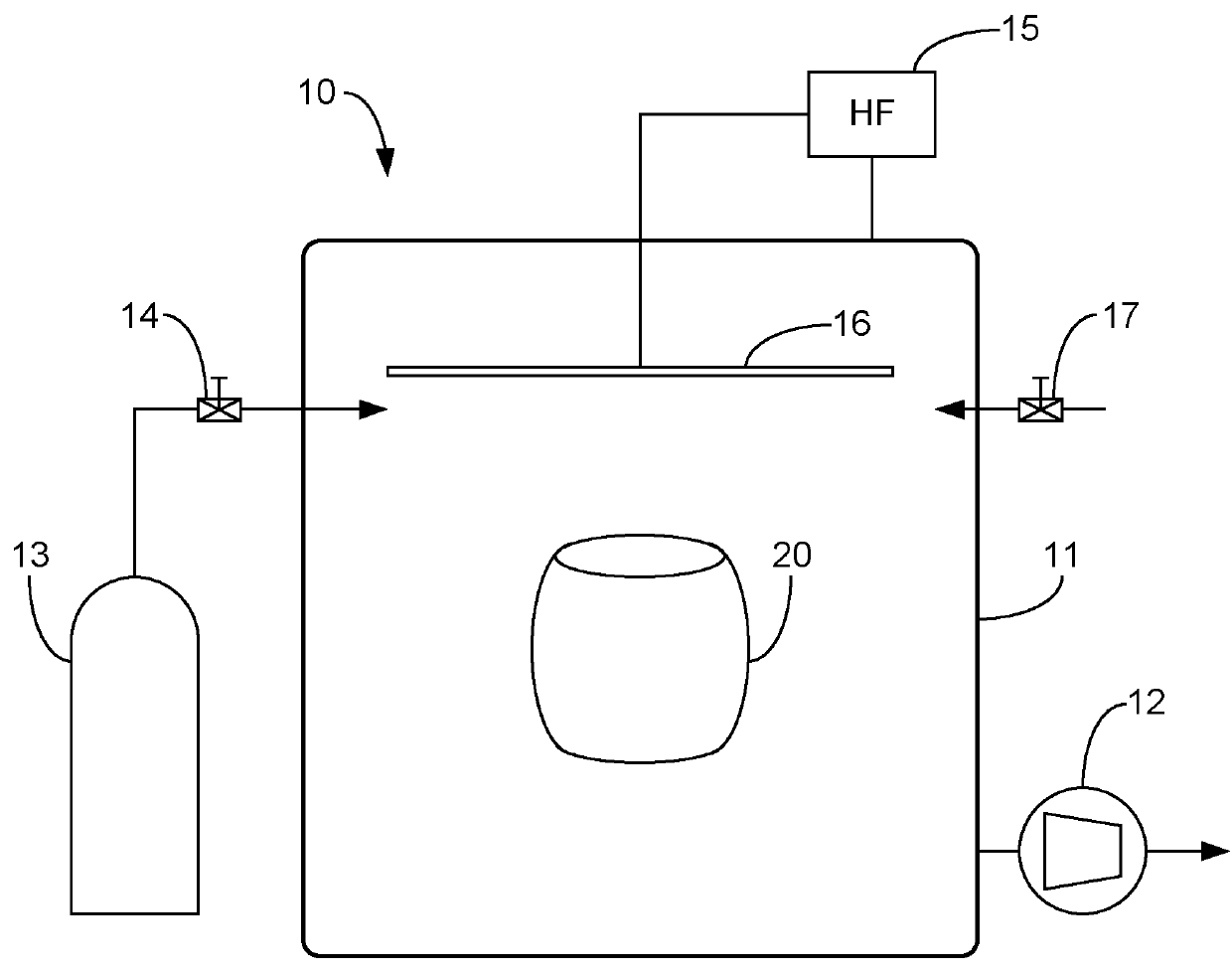

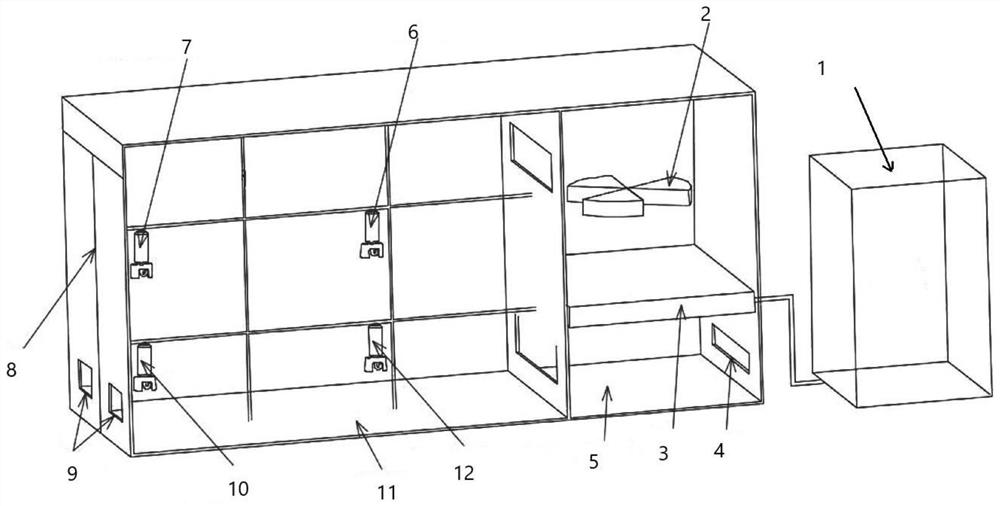

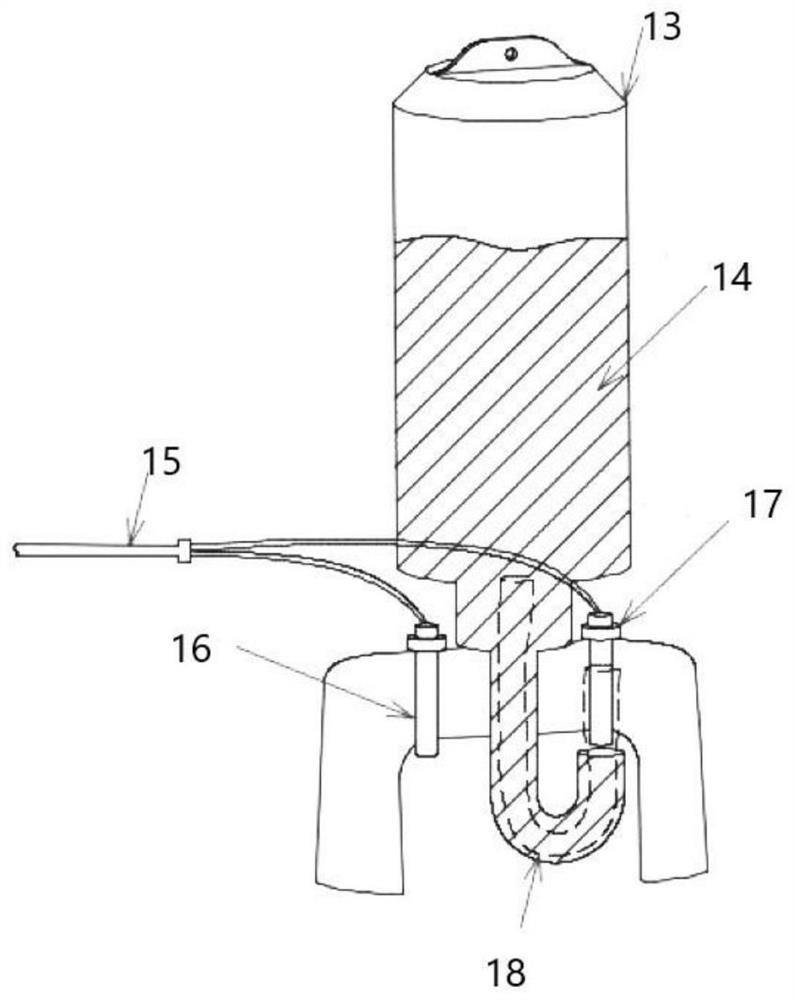

Semiconductor dehumidifier apparatus for cabinet

InactiveCN101392934AEfficient use ofIncrease air temperatureDispersed particle separationMachines using electric/magnetic effectsEvaporationEngineering

The invention relates to a cabinet semiconductor moisture suction device applicable to a wardrobe, a shoe cabinet, a file cabinet, a locker and a kitchen cabinet. The device comprises a mounting box 1, a radiator 2, a semiconductor refrigerating strip 3, a condenser 4, a water receiving disc 5, a fan 6, a water evaporation tank 7 and a drainage hole 8. The radiator 2 consists of two parts, namely an inner radiator 22 inside the mounting box and an outer radiator 21 which runs through an open hole reserved in the mounting box and is exposed outside the mounting box. When the semiconductor refrigerating strip operates, the fan also operates simultaneously. Wind blown out from the fan brings heat on the surface of the radiator away and heats air in the cabinet, thereby accelerating the evaporation of moisture of an object; simultaneously, moisture in air is condensed to dew by the condenser, is gathered on the water receiving disc and flows to the water evaporation tank 7 through the drainage hole 8; and the heat of the outer radiator 21 is utilized to evaporate condensed water to the air outside the cabinet, thereby avoiding manual treatment on the condensed water.

Owner:李耀强

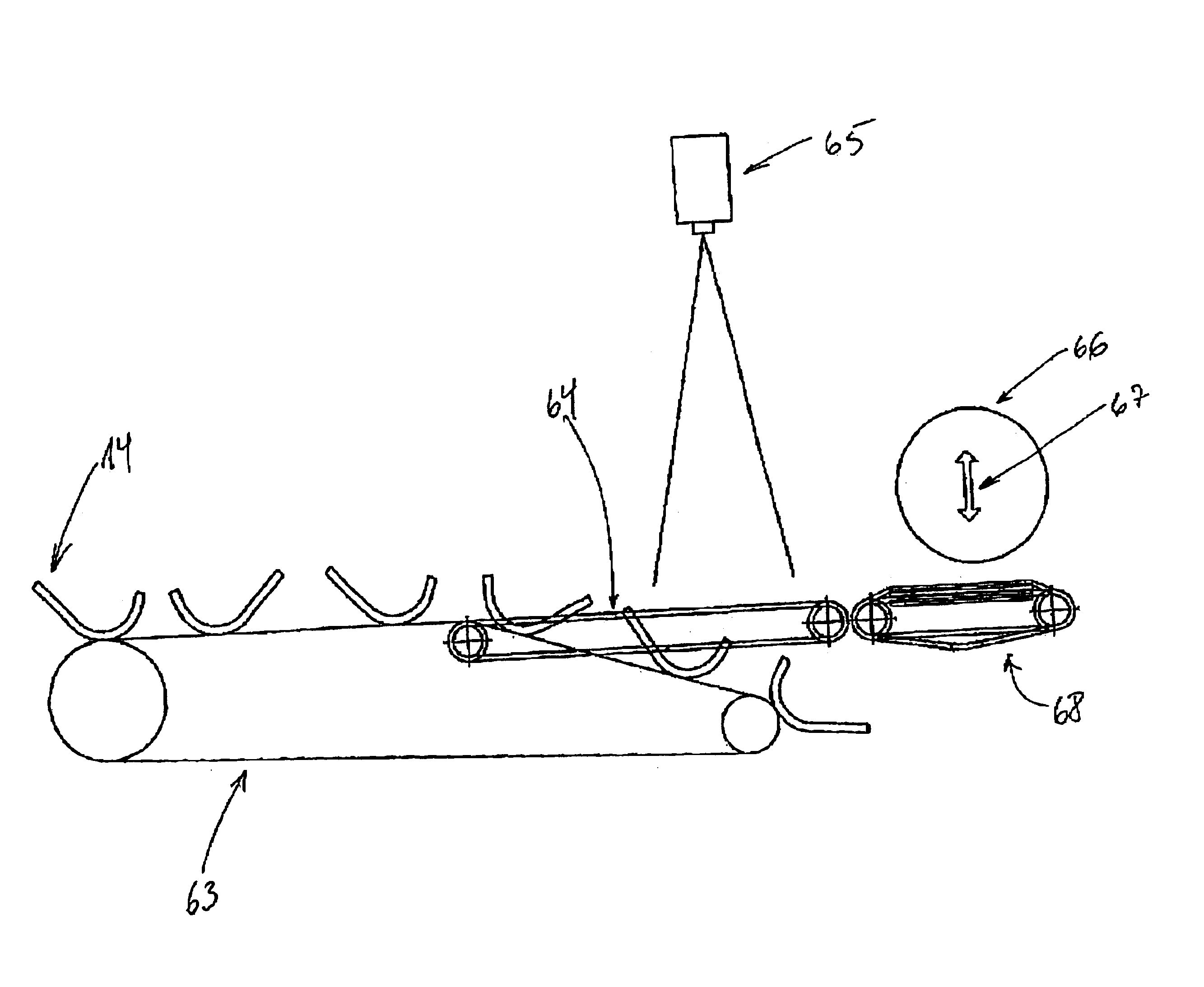

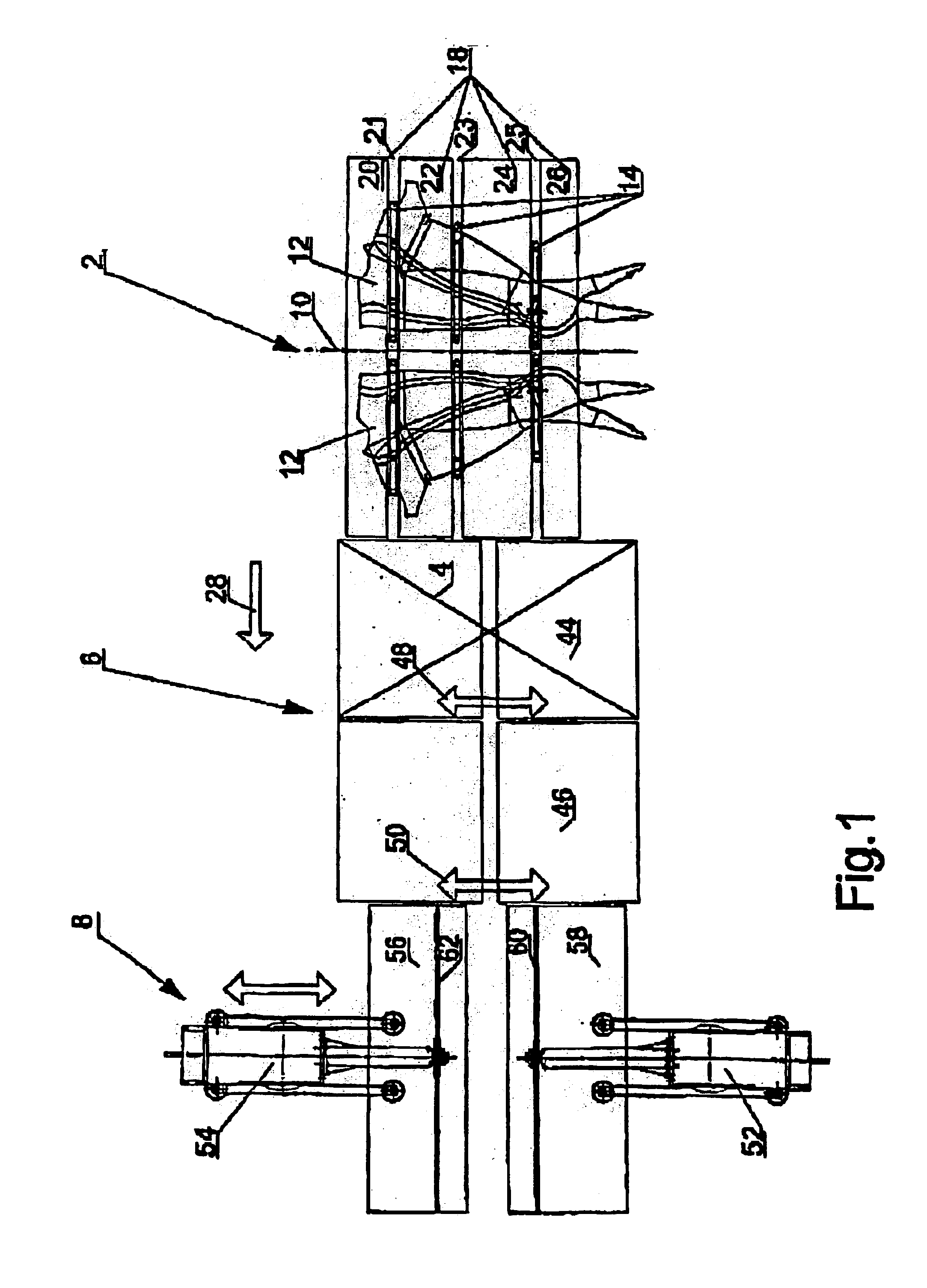

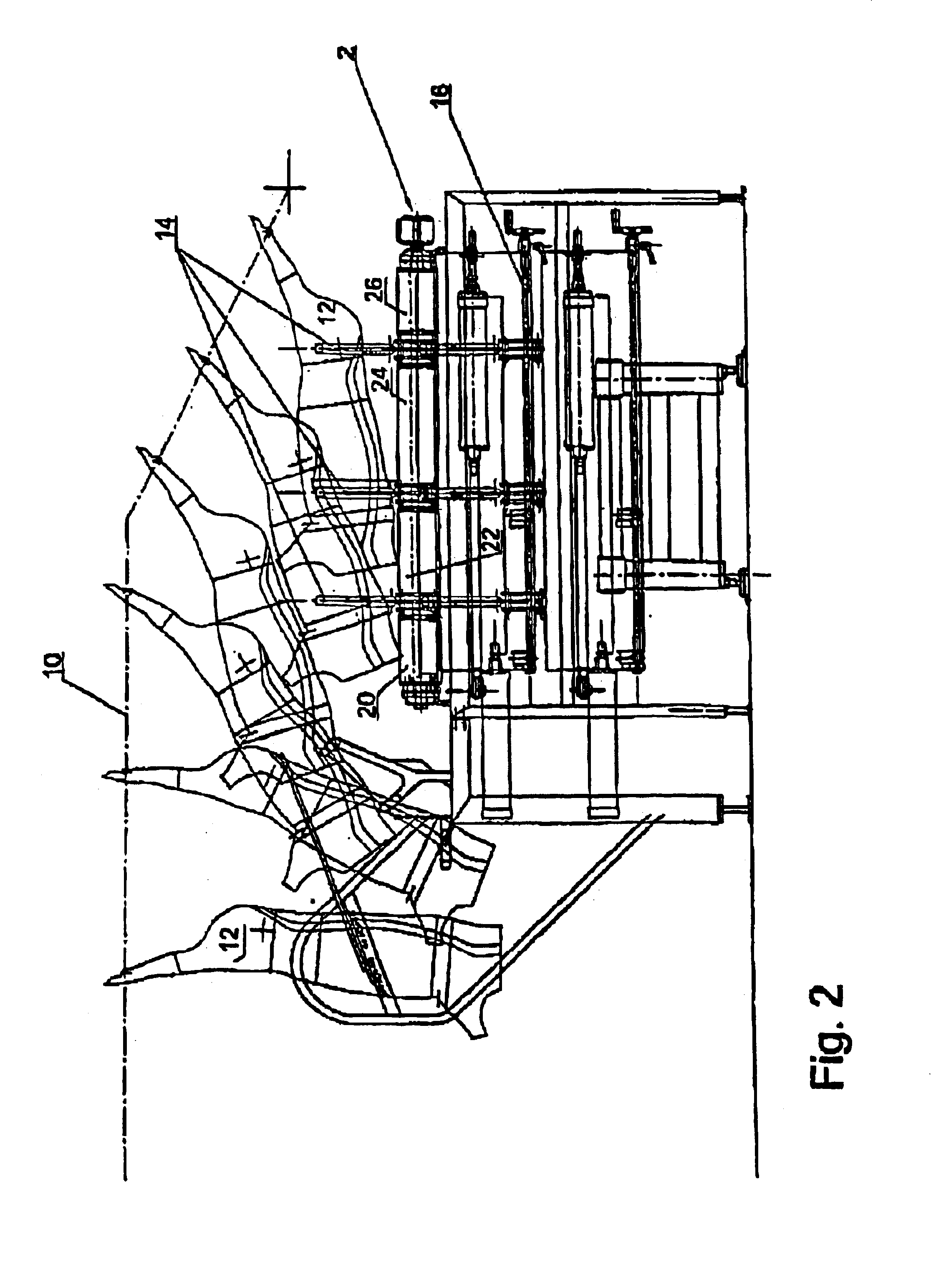

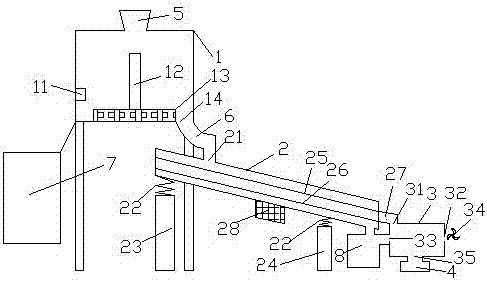

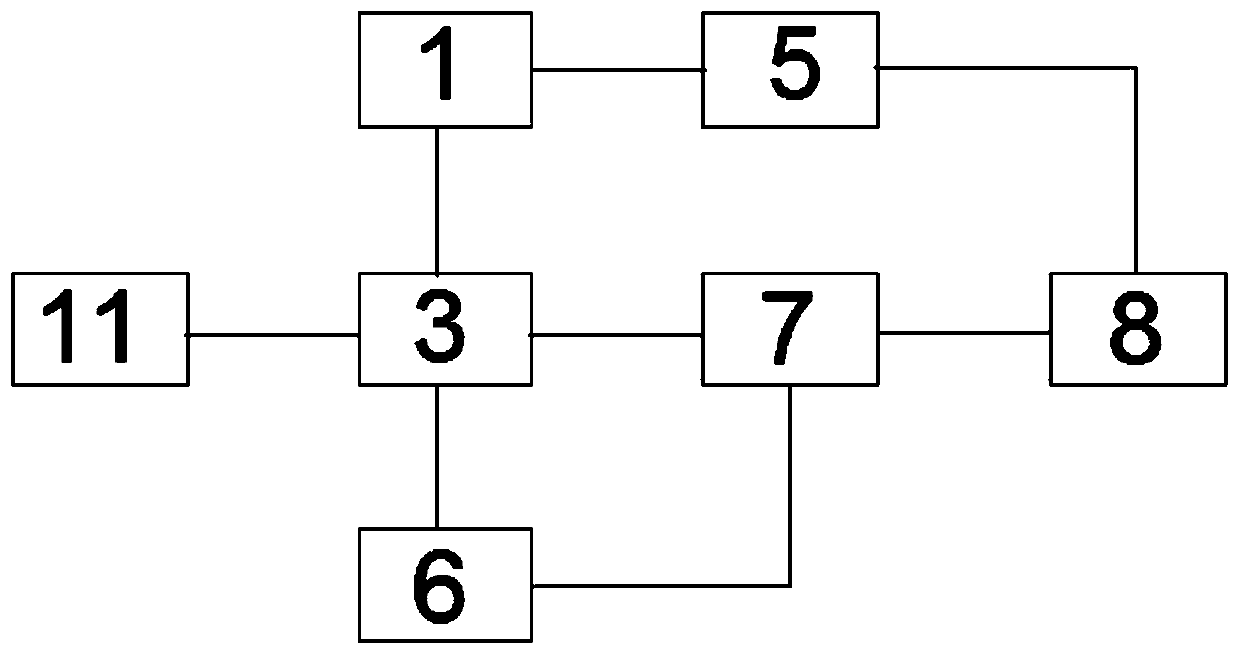

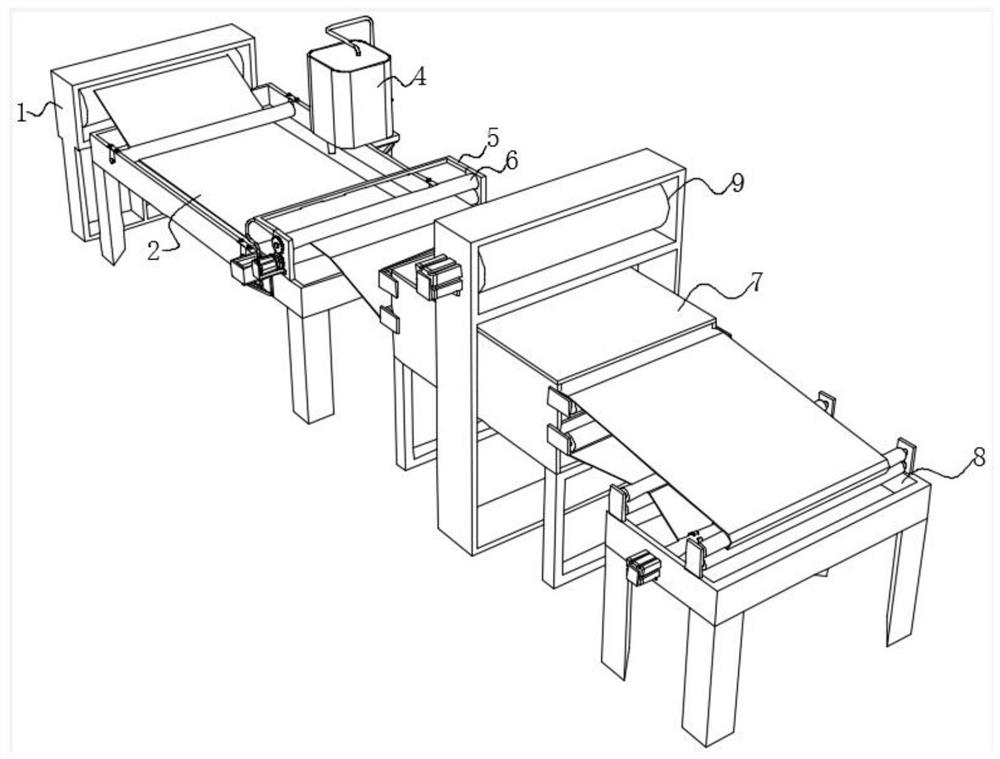

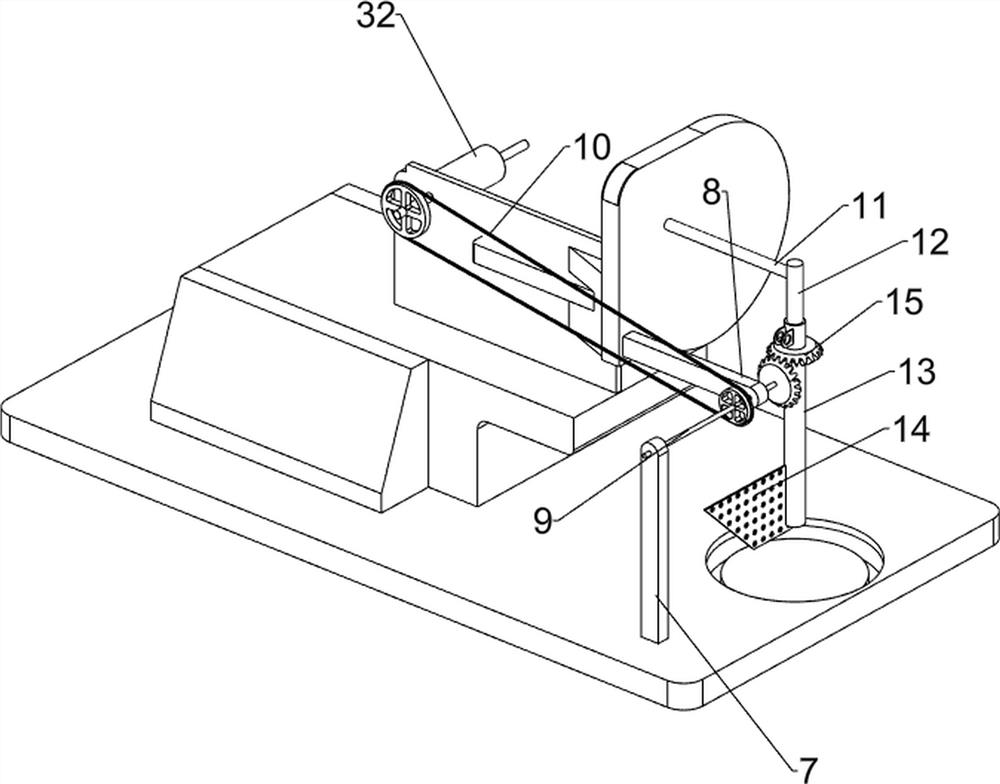

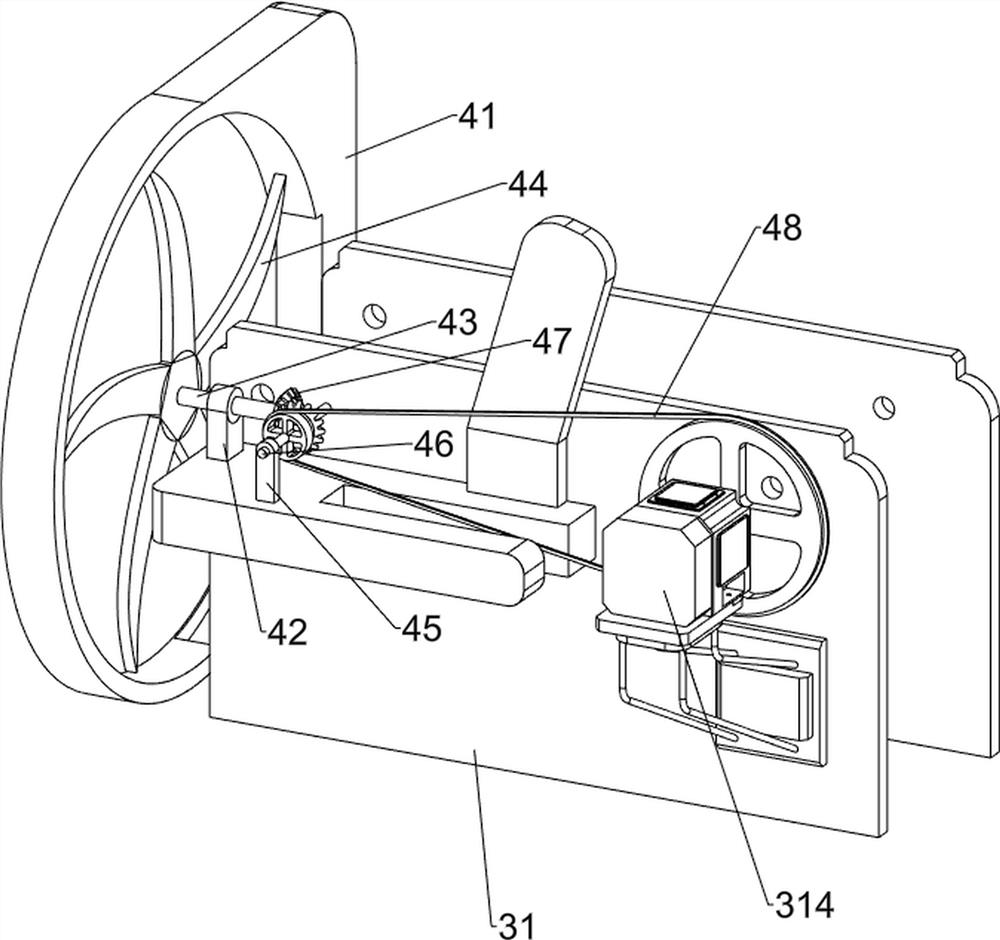

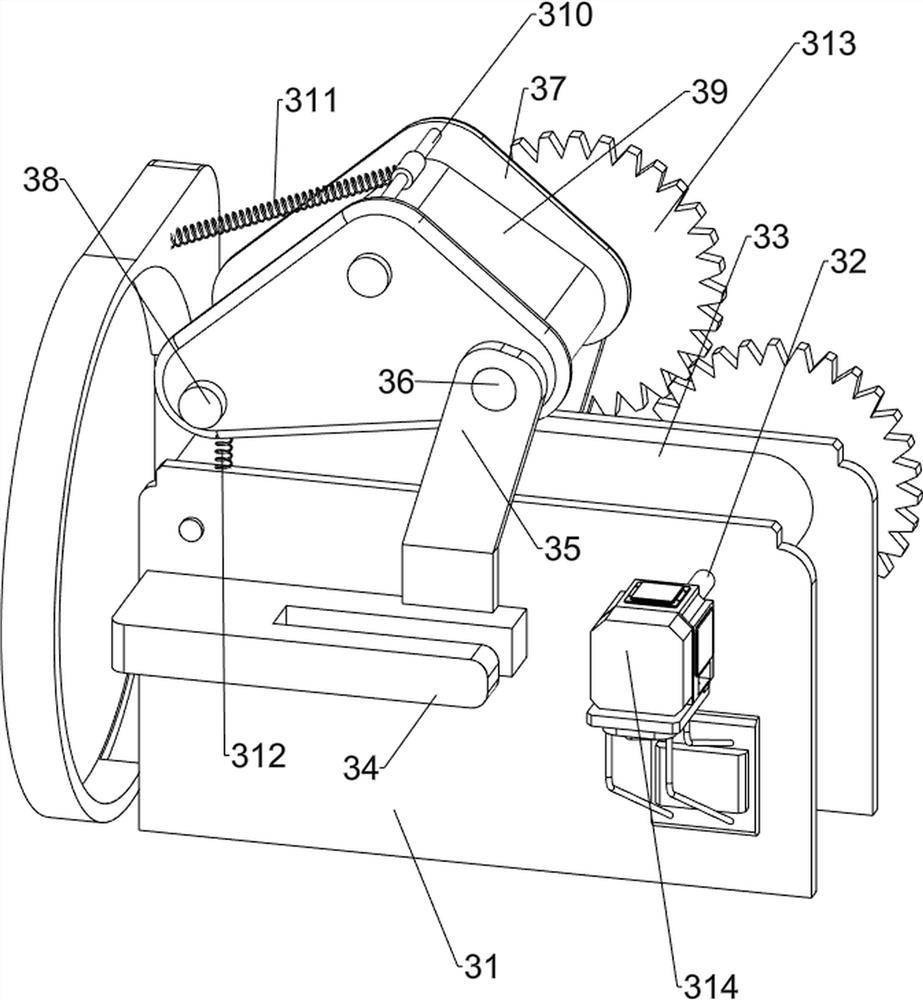

Laying-down system and vision-based automatic primal cutting system in connection therewith

InactiveUS6860804B2Improve gripIncrease frictionMeat processing plantsSlaughtering accessoriesVision based systemsVision based

In the primal cutting-up of half carcasses of animals (12), vision systems are known whereby the determination of one or more fix points on the carcasses takes place, and where on the basis of the position of these points a visualization of the ideal cut line is effected. But the primal cutting-up of carcasses (12) has hitherto been carried out with manually-operated saws on the basis of operator evaluation. However, the use of manually-operated saws involves the possibility of deviations in relation to the ideal cut line, and the manual work is very monotonous and fatiguing for the operators. There is thus disclosed a system as well as a laying-down module (2) and a vision-based system for automatic primal cutting-up of half carcasses, comprising a laying-down module with a laying-down conveyor (18), and a laying-down and angle-positioning module (6) with sideways displaceable conveyors for positioning of a relevant carcass (12) for sawing-up in a subsequent saw module (8), and a method for the execution of automatic primal cutting-up of meat items, namely half carcasses of animals.

Owner:HUMBOLDT

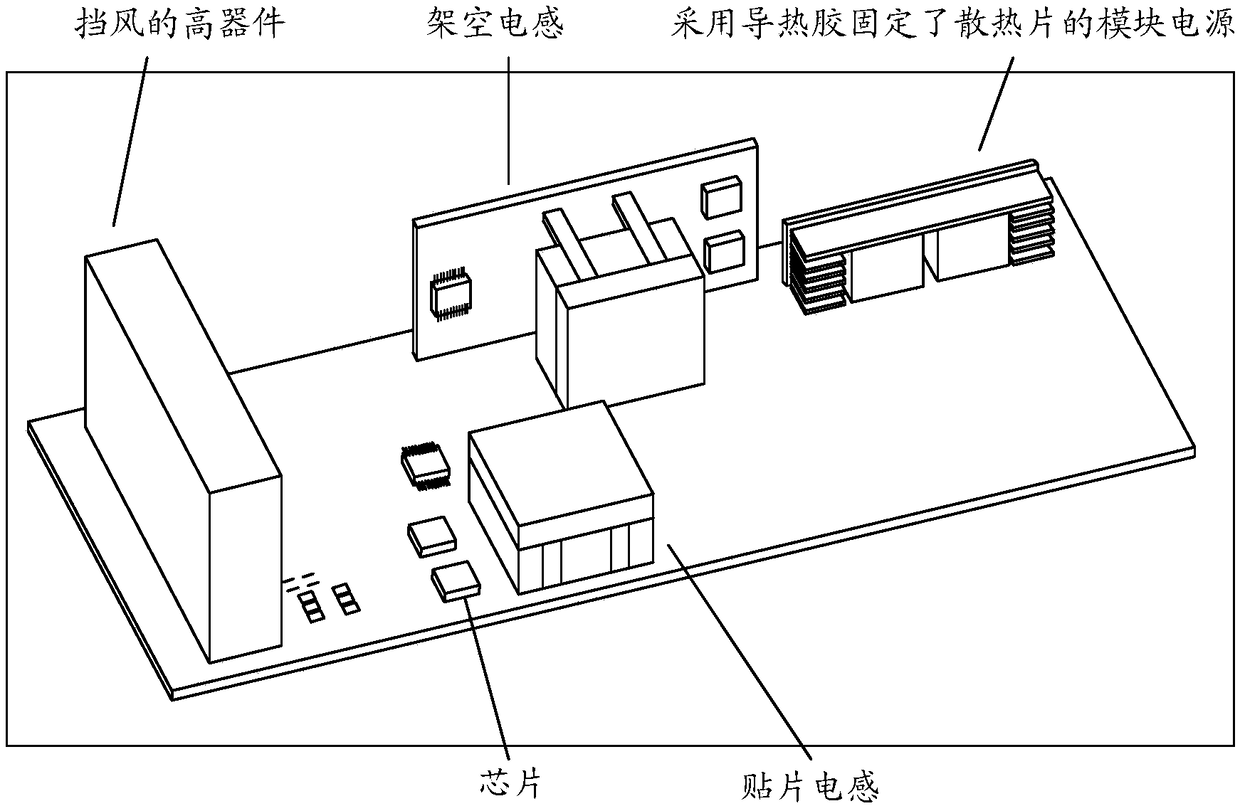

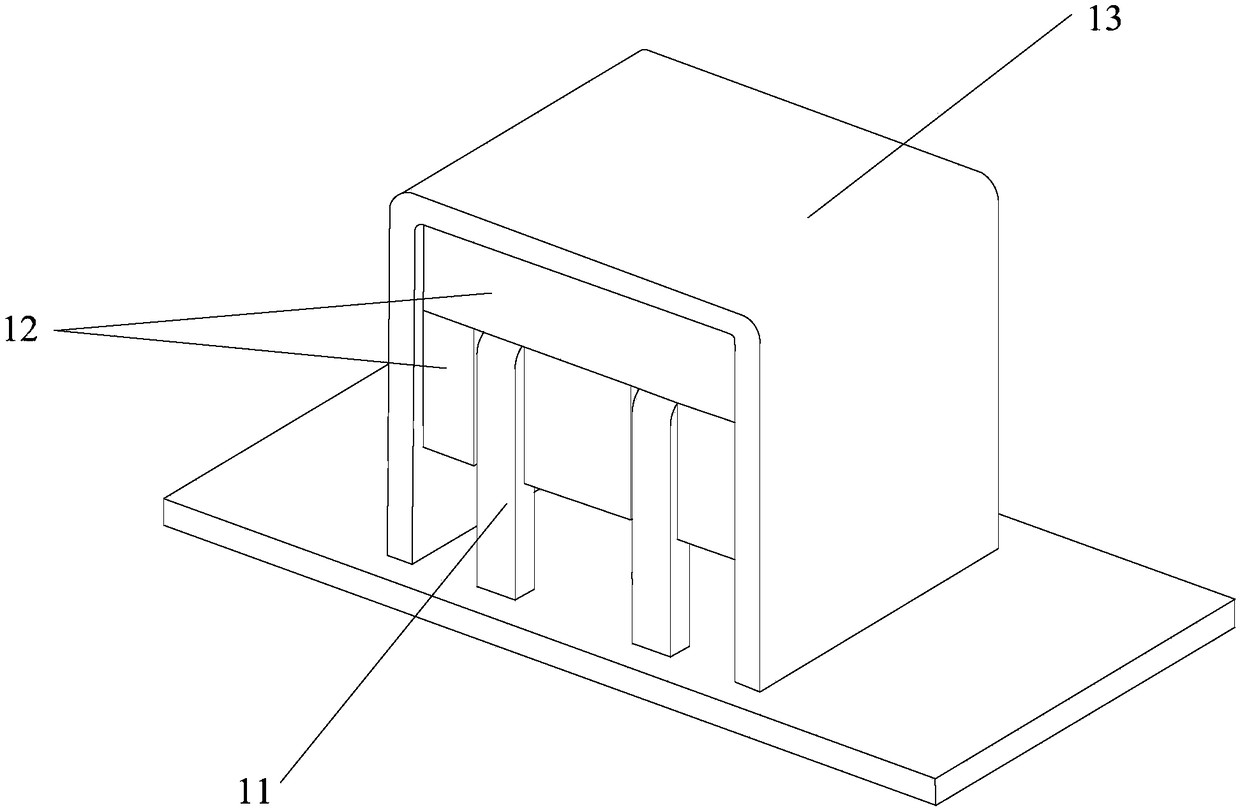

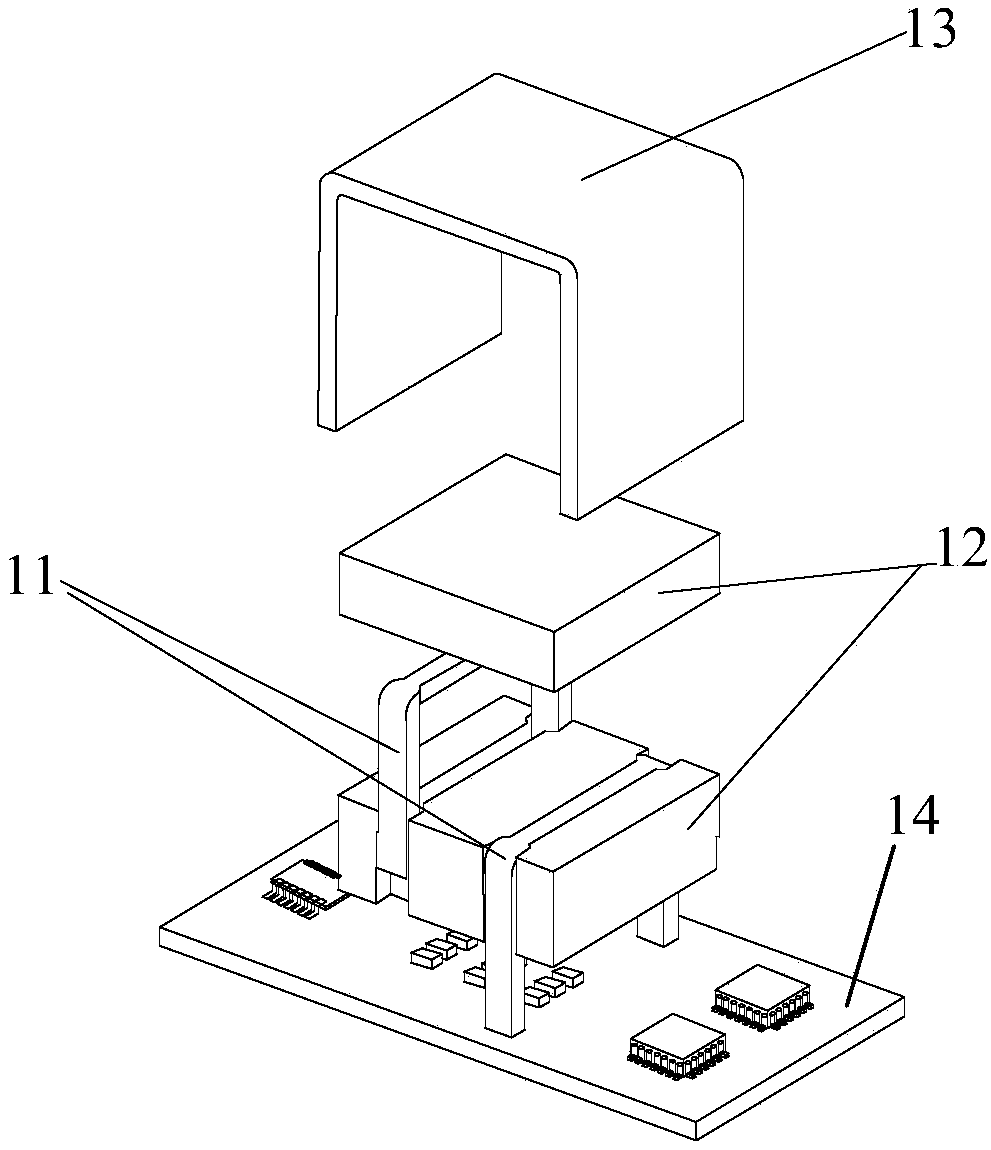

Heat dissipation structure

ActiveCN108990362AImprove cooling effectIncrease the areaTransformers/inductances coolingModifications by conduction heat transferHeat sinkConduction channel

The invention discloses a heat dissipation structure. The heat dissipation structure comprises a heat dissipation device, a first type heat generating assembly and a second type heat generating group.The first type heating component comprises a winding and a magnetic core. The second type heating component comprises a heating device. The heat dissipation device comprises a heat dissipation fin and a circuit board with a heat conduction channel. Wherein the winding is arranged between the magnetic core and the magnetic core, and the first type heating component is supported on the circuit board by the winding and has an overhead structure with respect to the circuit board; The heat dissipation fin cover is arranged on the outer surface of the first type heating component, and is integrallystructured with the first type heating component, wherein, the height of the integrally structured fin cover is greater than or equal to a preset value; The bottom of the heating device is provided with a first pad, and the first pad is arranged on the circuit board. Heat sink is soldered on the circuit board through one or more soldering terminals; The heat of the heating device is transferred to the circuit board through the first pad and to the heat sink through the heat conduction channel on the circuit board.

Owner:ZTE CORP

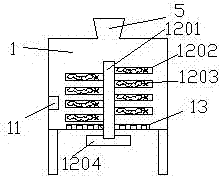

Wheat impurity-removing device

InactiveCN107047757ASimple structureReduce labor intensitySievingGas current separationMoisture sensorMechanical engineering

The invention discloses a wheat impurity-removing device. The wheat impurity-removing device comprises a drying chamber, a vibration screening device, a wind-selecting mechanism and a wheat collecting device, the drying chamber is located above the vibration screening device, the wind-selecting mechanism is located below the vibration screening device, the wheat collecting device is located below the wind-selecting mechanism, wheat enters the drying chamber from a feeding hopper, when a pressure sensor at the bottom of the drying chamber detects that the weight of the wheat in the drying chamber exceeds a specified value, addition of the wheat is stopped, a drying device is started to dry the wheat, when a humidity sensor detects that the humidity of the wheat meets requirements, the drying chamber opens a drying chamber discharging opening, the wheat enters the vibration screening device, a vibration motor drives the vibration screening device to vibrate, after impurities are removed by the vibration screening device, the wheat enters the wind-selecting mechanism, and awn of wheat and other light-weight impurities are removed. The wheat impurity-removing device is simple in structure and wide in application range, can automatically remove the impurities of the wheat and drying the wheat, and has the advantages of being high in impurity-removing efficiency and drying speed.

Owner:河南颇文商贸有限公司

Method of steam sterilisation of medical products

InactiveUS20030074862A1Low costLess materialPackage sterilisationLavatory sanitoryCardboardMedical product

Owner:FRANZ EFFENBERGER +1

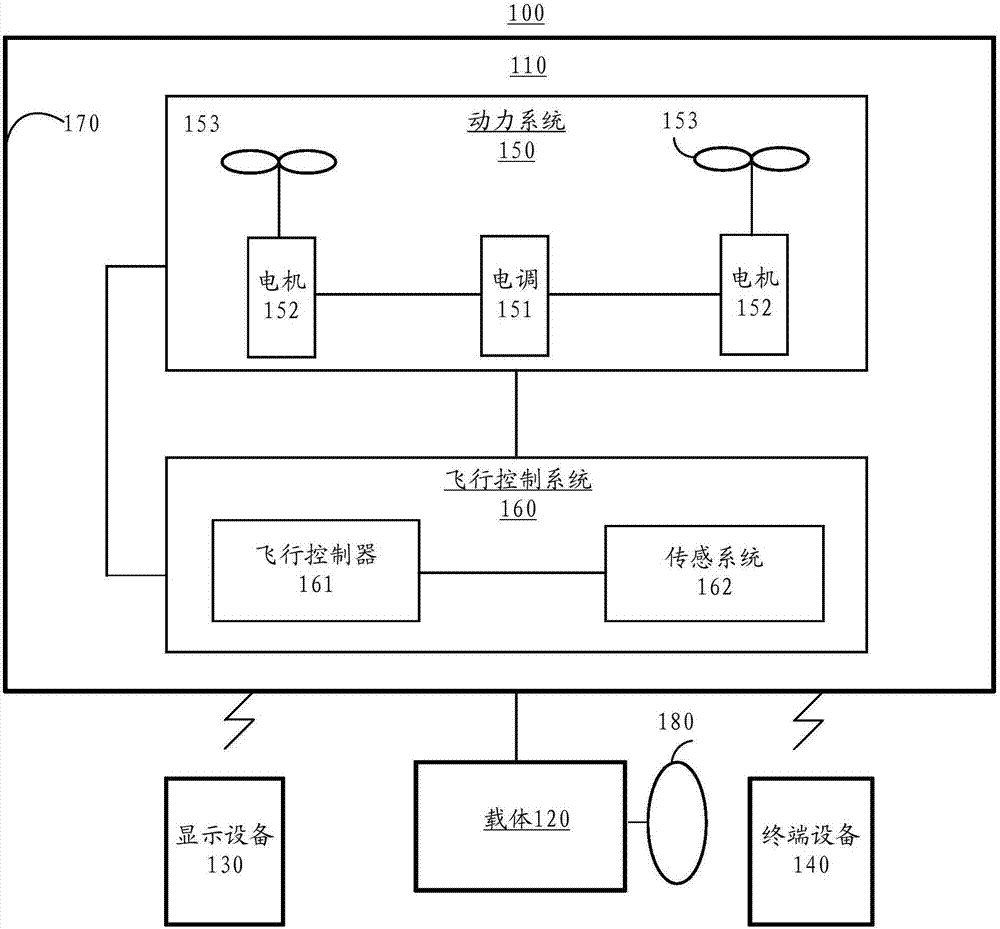

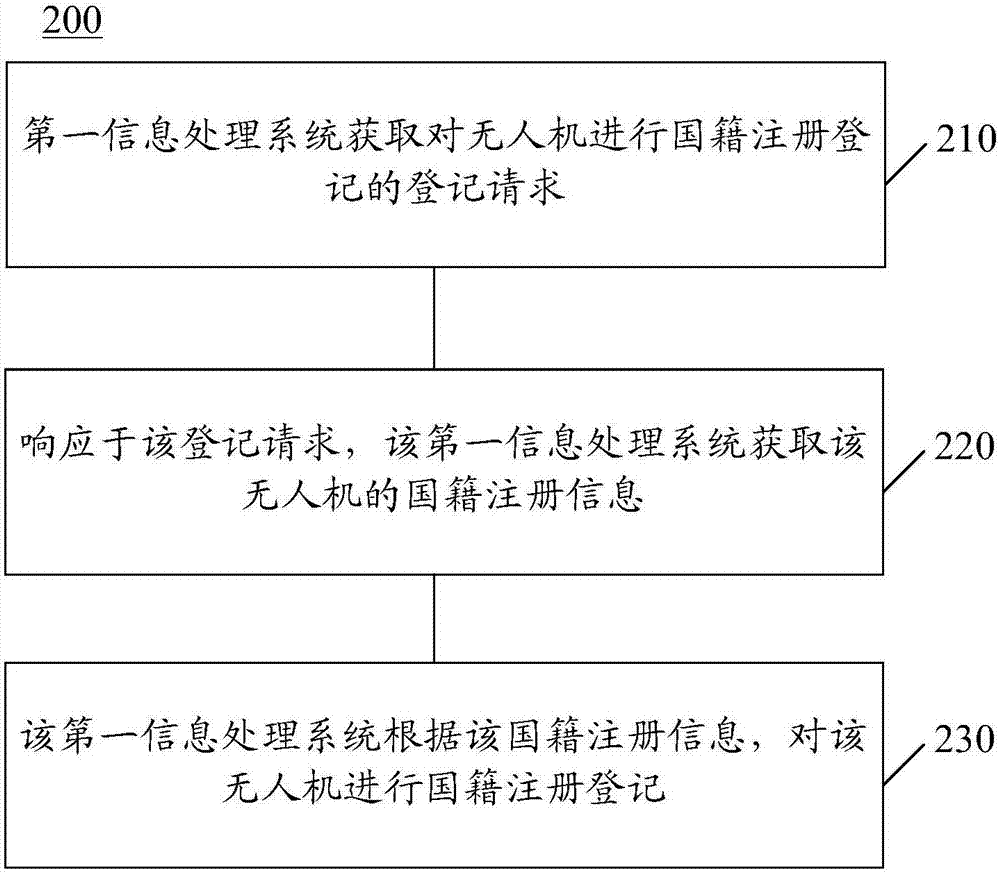

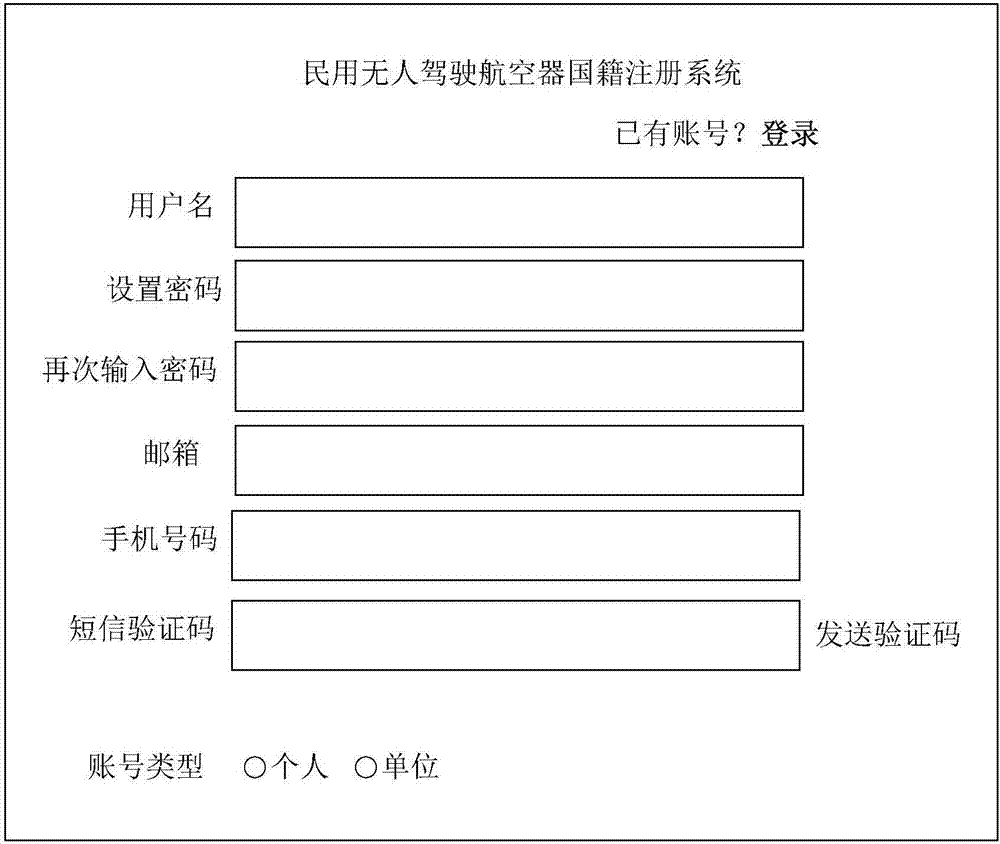

Information processing method and system, and unmanned aerial vehicle controlling method and device

ActiveCN107087440AAvoid manual processingReduce labor costsTransmissionInformation processingComputer vision

The invention relates to an information processing method, an unmanned aerial vehicle controlling method, an information processing device and an unmanned aerial vehicle controlling device. Nationality login and registration or airworthiness certification and registration of the unmanned aerial vehicle are achieved. The information processing method comprises that a first information processing system acquires a registration request for carrying out nationality login and registration; in response to the registration request, the first information processing system acquires the nationality registration information of the unmanned aerial vehicle; the first information processing system carries out nationality login and registration on the unmanned aerial vehicle.

Owner:SZ DJI TECH CO LTD

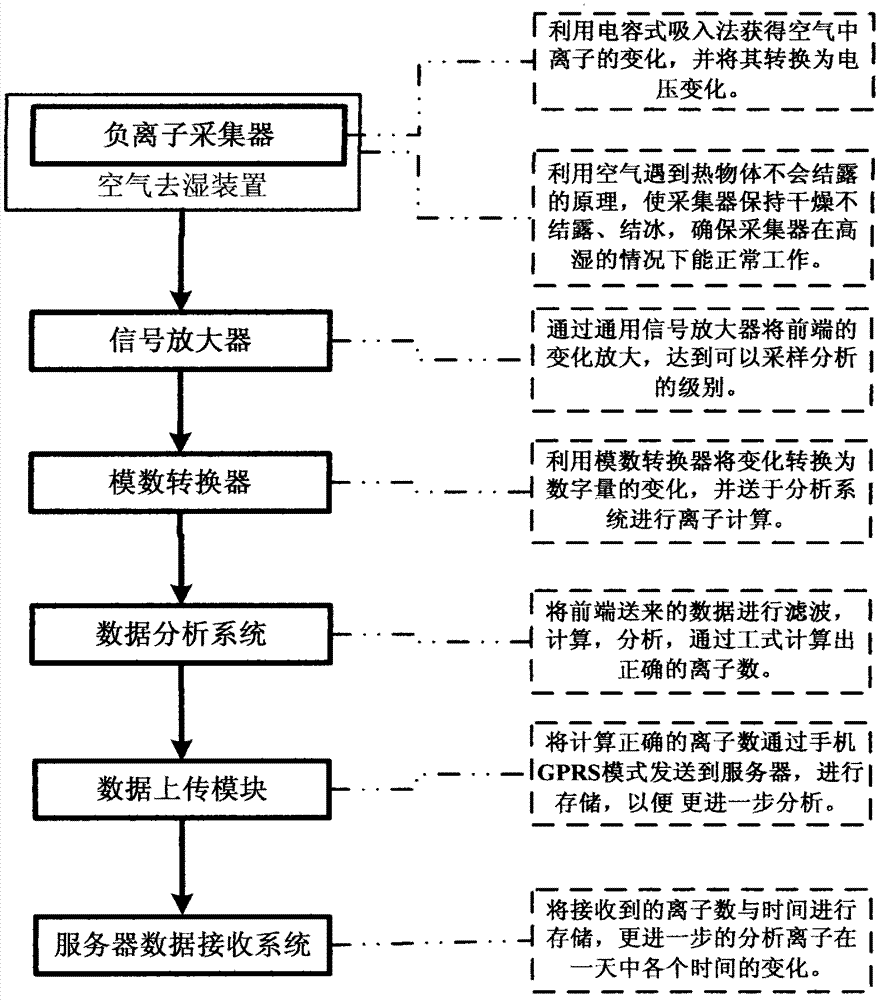

Atmospheric negative oxygen ion monitoring system and monitoring method thereof

InactiveCN103197030AStable detectionAccurate detectionIndividual particle analysisHigh humidityOxygen ions

The invention discloses an atmospheric negative oxygen ion monitoring system and a monitoring method thereof, and relates to the field of measurement of the free electron namely atmospheric negative oxygen ion. The system comprises a negative ion collector, a signal amplifier, an analog to digital converter, a data analysis system, a data upload module and a server data receiving system. The negative ion collector is provided with an air moisture-removal device. The invention solves the problem of measurement of negative ions in air with high humidity, so that the device can conduct all-weather work under high humidity conditions, and has advantages of simple operation and strong practicability.

Owner:谢文斌

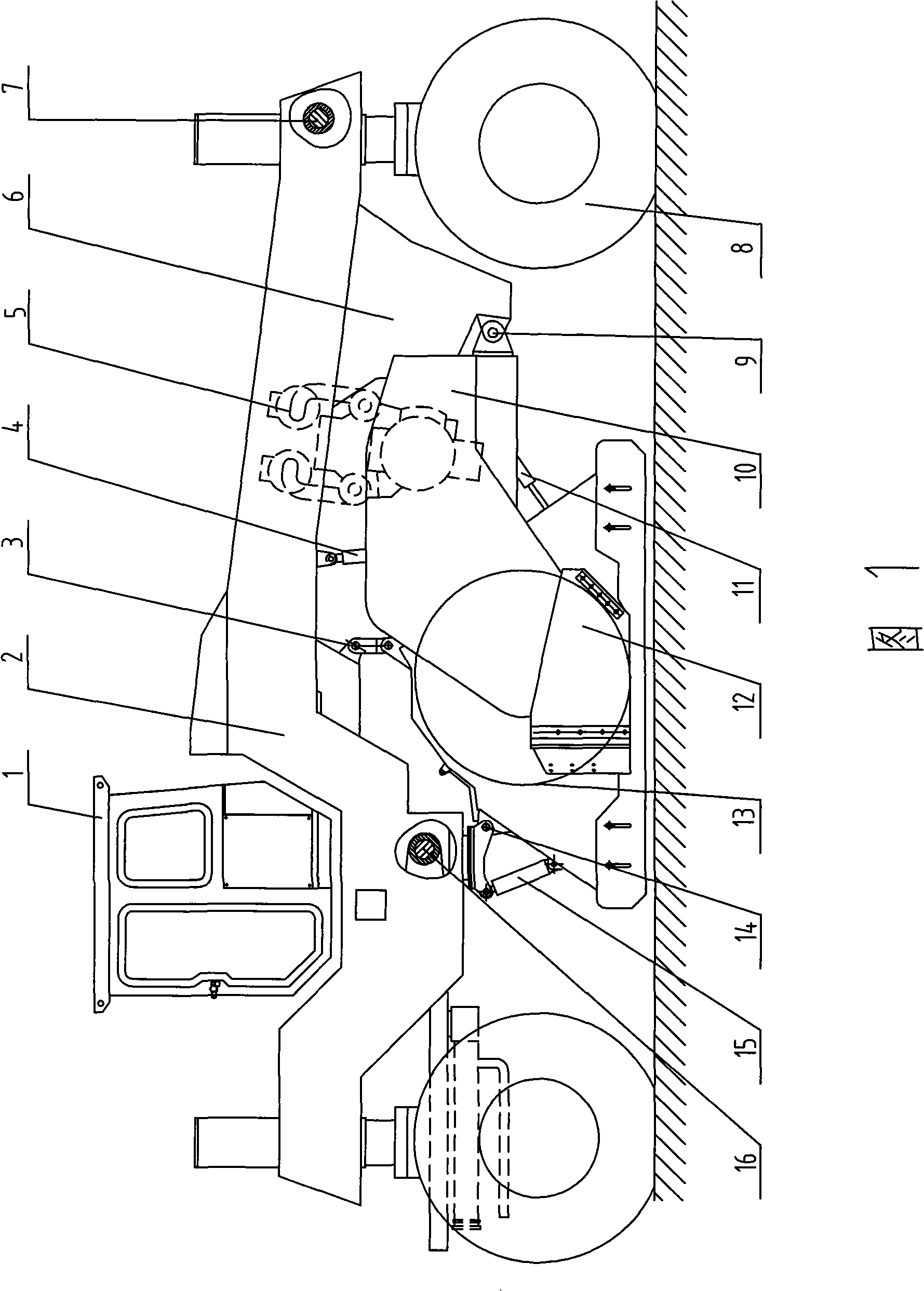

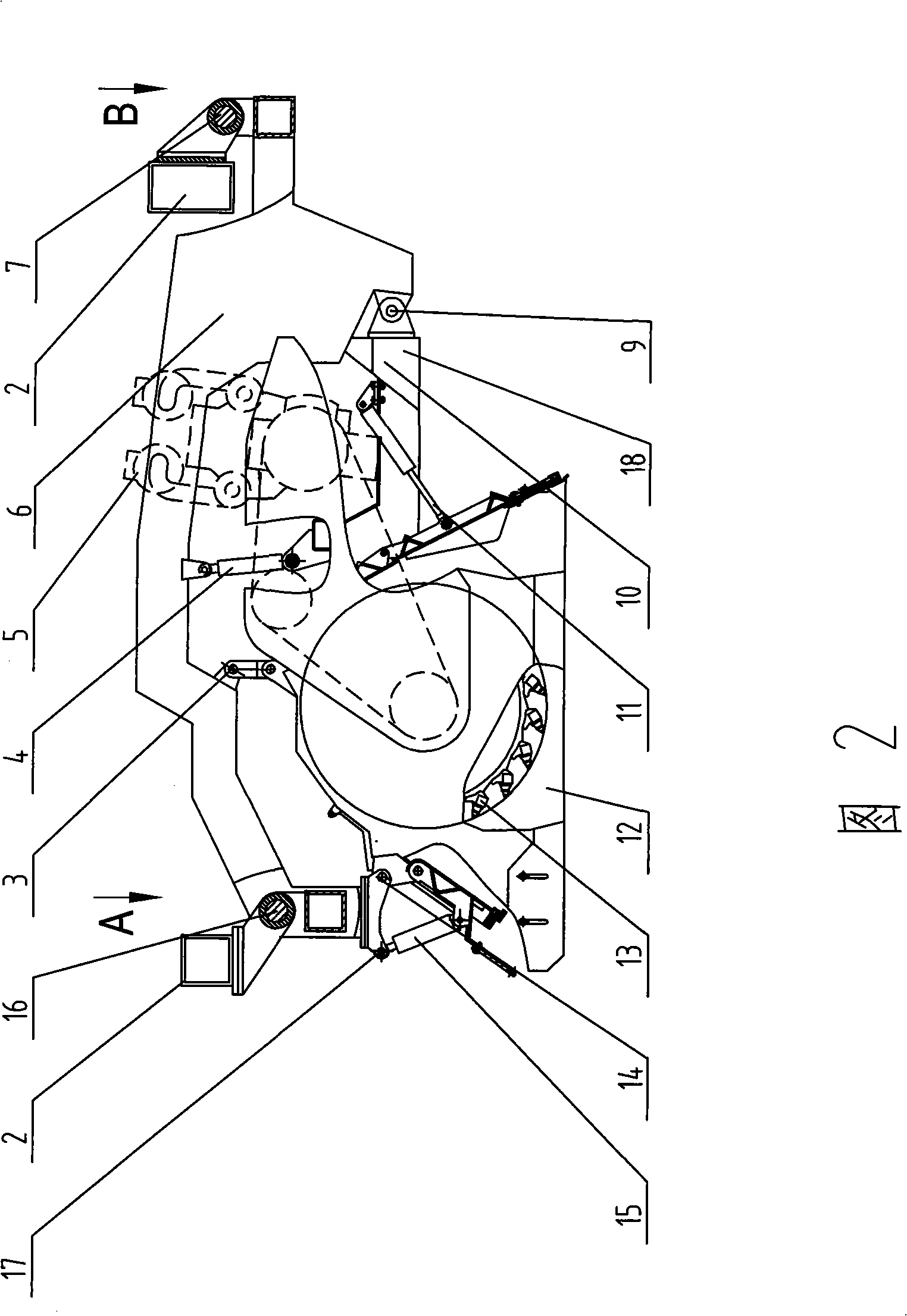

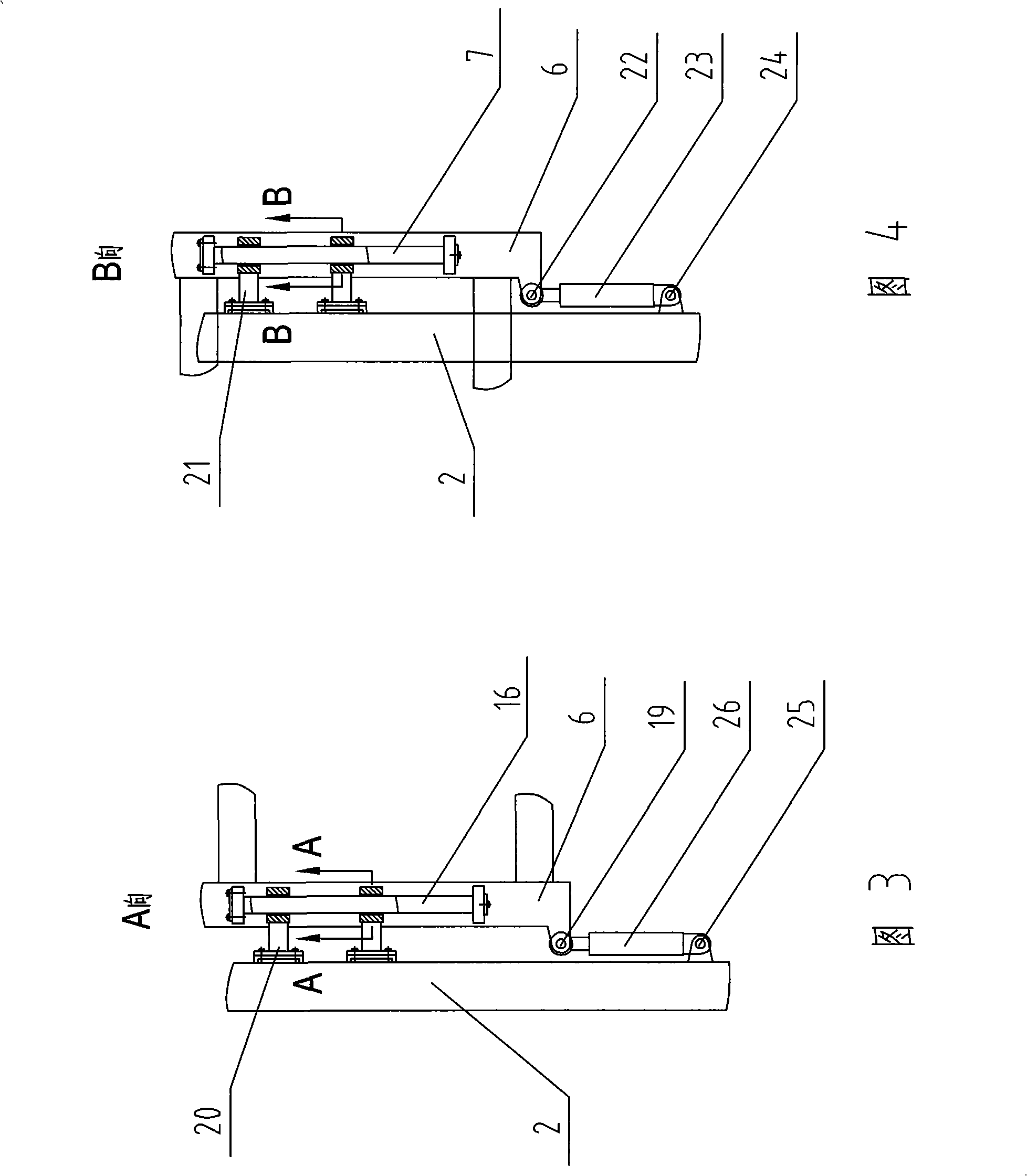

Cold recycler with cross sliding type working roll

InactiveCN101514540AEasy to cleanSolve problems such as inability to clean up completelyRoads maintainenceWork rollWork performance

The invention relates to a cold recycler with a cross sliding type working roll, and effectively solves the problems that the existing device can not completely clean road edge and the like. The cold recycler comprises a four-wheel drive running mechanism, a car body, a cab, an adjusting rack, an outer cover of a built-in working roll and a drive mechanism thereof. The key technical aspects are: a monolithic construction is applied to the cab, and an adjusting and control mechanism of the working roll is connected with the car body by a transverse sliding mechanism a transversely movable drive hydro cylinder hinged on the car body is adopted to drive a transversely movable rack of the transverse sliding mechanism to move along the direction of a sliding shaft and a sliding rail of the transverse sliding mechanism; the back end of the adjusting rack is hinged with the transversely movable rack by a spin axis, the two sides of the front end of the adjusting rack is hinged with the transversely movable rack by a lifting drive hydro cylinder, and the outer cover is hinged with the transversely movable rack by a front connecting lug and a back connecting lug. The cold recycler of the invention has the advantages of rational design, compact structure, convenient use and maintenance, complete cleaning of the road surface and full use of the road edge material, saving of labor force and raw materials and remarkable improvement of working performance and cost performance.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

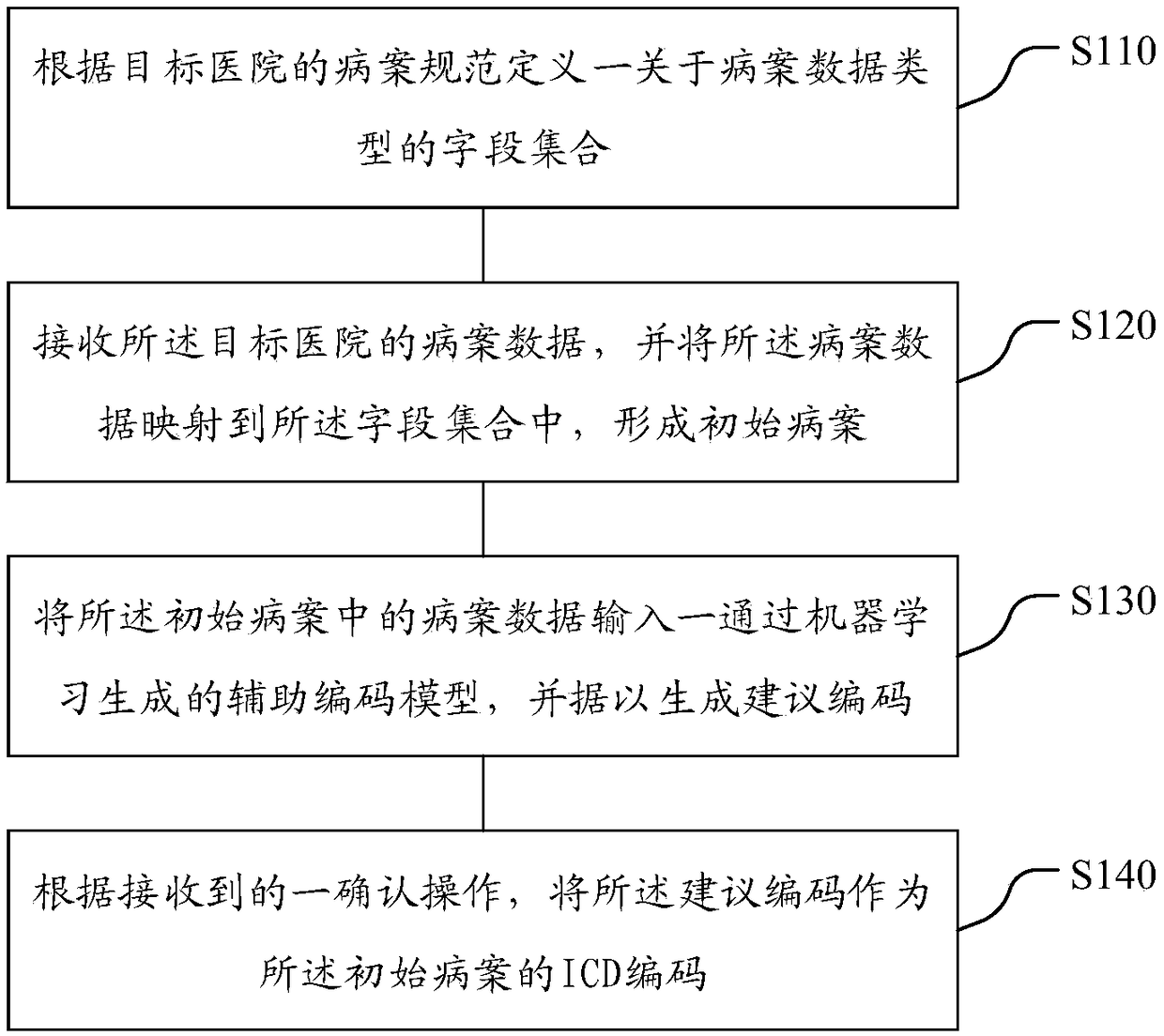

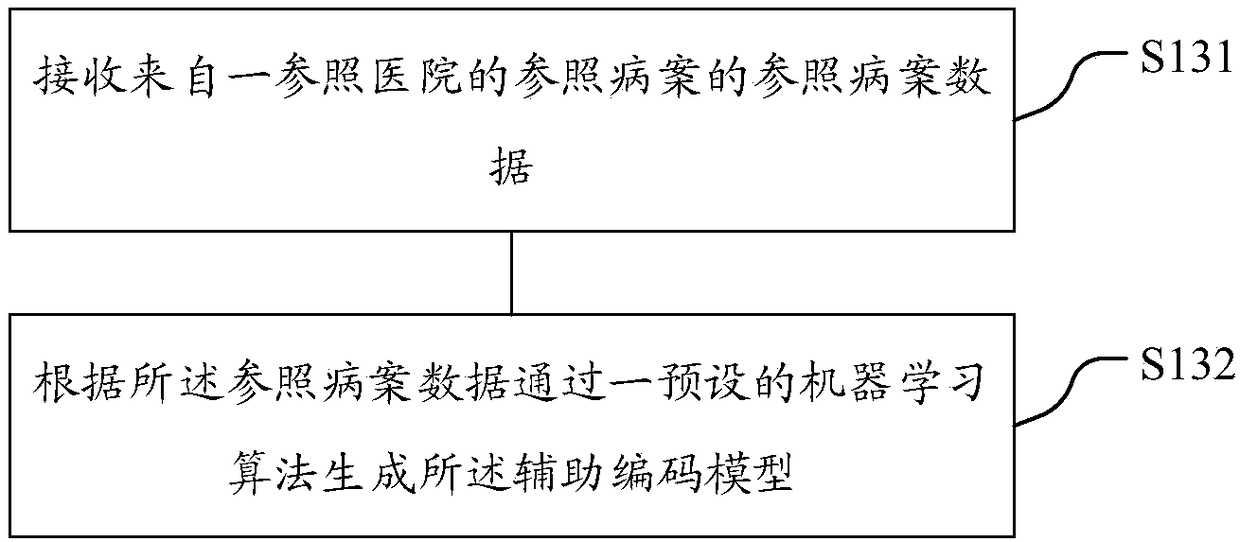

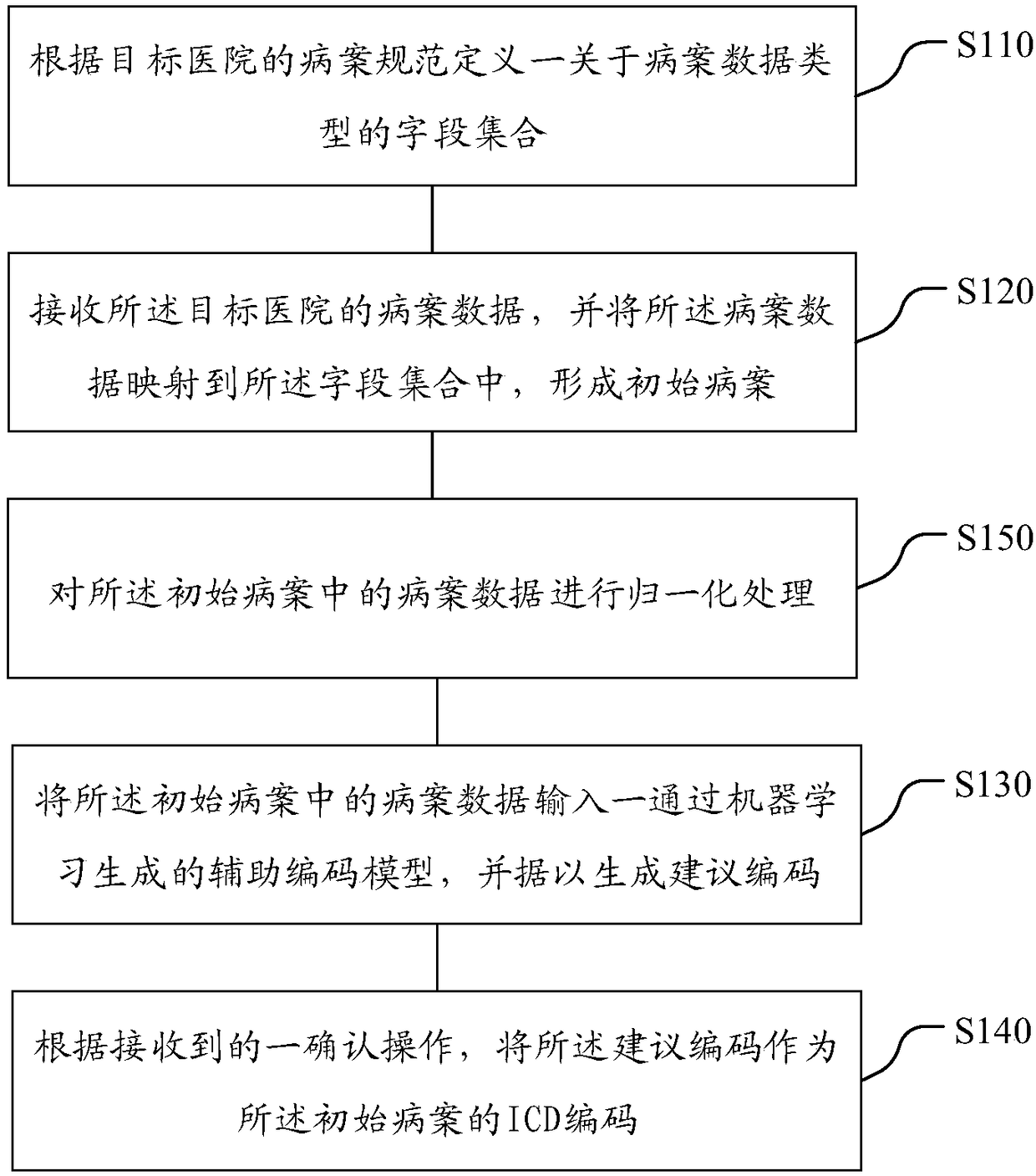

Medical record ICD coding method and system

InactiveCN108320778ARealize automatic generationAvoid manual processingSpecial data processing applicationsPatient-specific dataMedical recordDisease

The invention relates to a medical record ICD (International Classification of Diseases) coding method and system. The medical record ICD coding method comprises the following steps: defining a fieldset about medical record data type according to the medical record specification of a target hospital; receiving the medical record data of the target hospital, and mapping the medical record data tothe field set to form an initial medical record; inputting the medical record data in the initial medical record to an auxiliary coding model generated by machine learning, and generating a proposed code; and taking the proposed code as the ICD code of the initial medical record according to a confirmation operation received.

Owner:YIDU CLOUD (BEIJING) TECH CO LTD

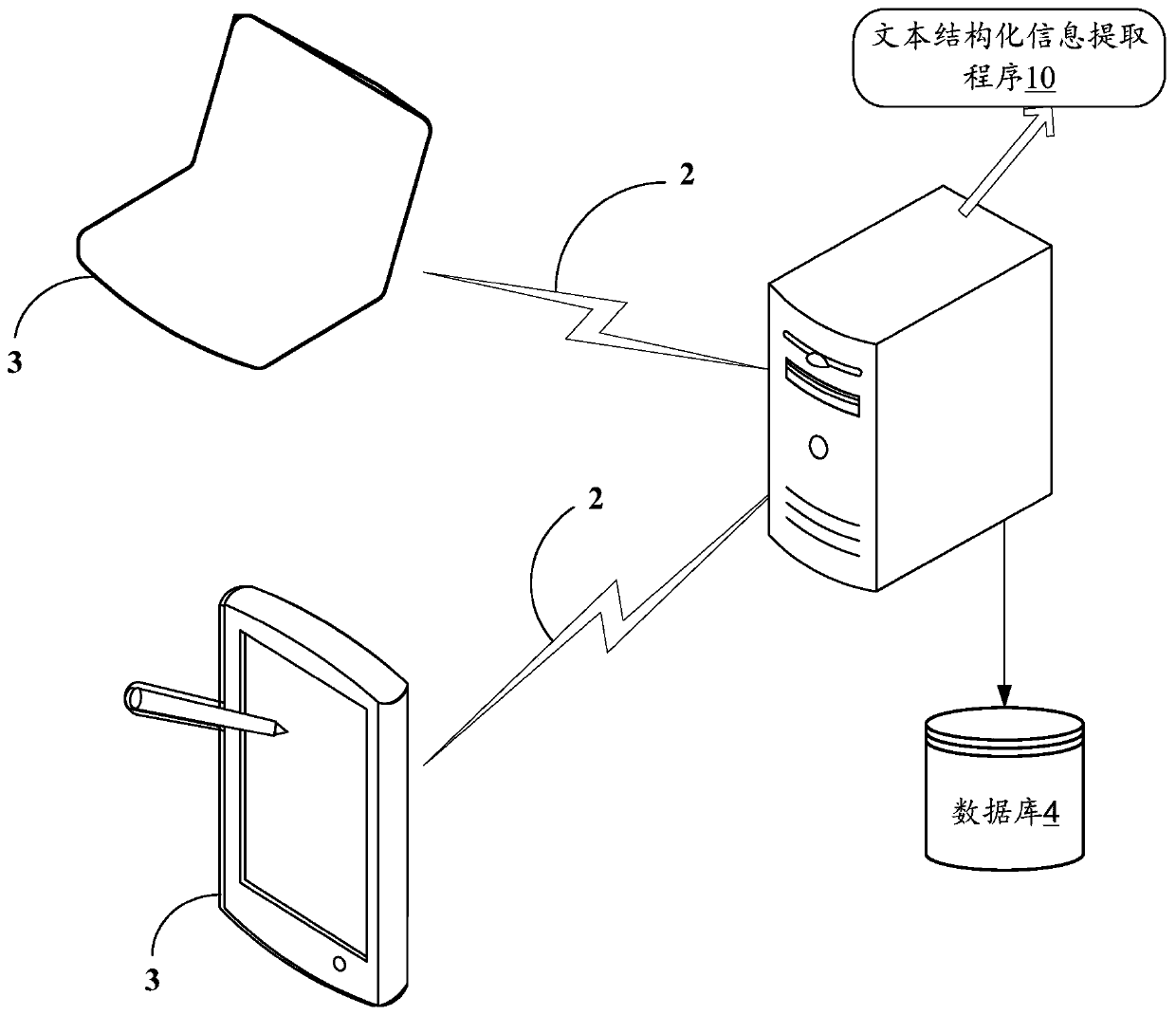

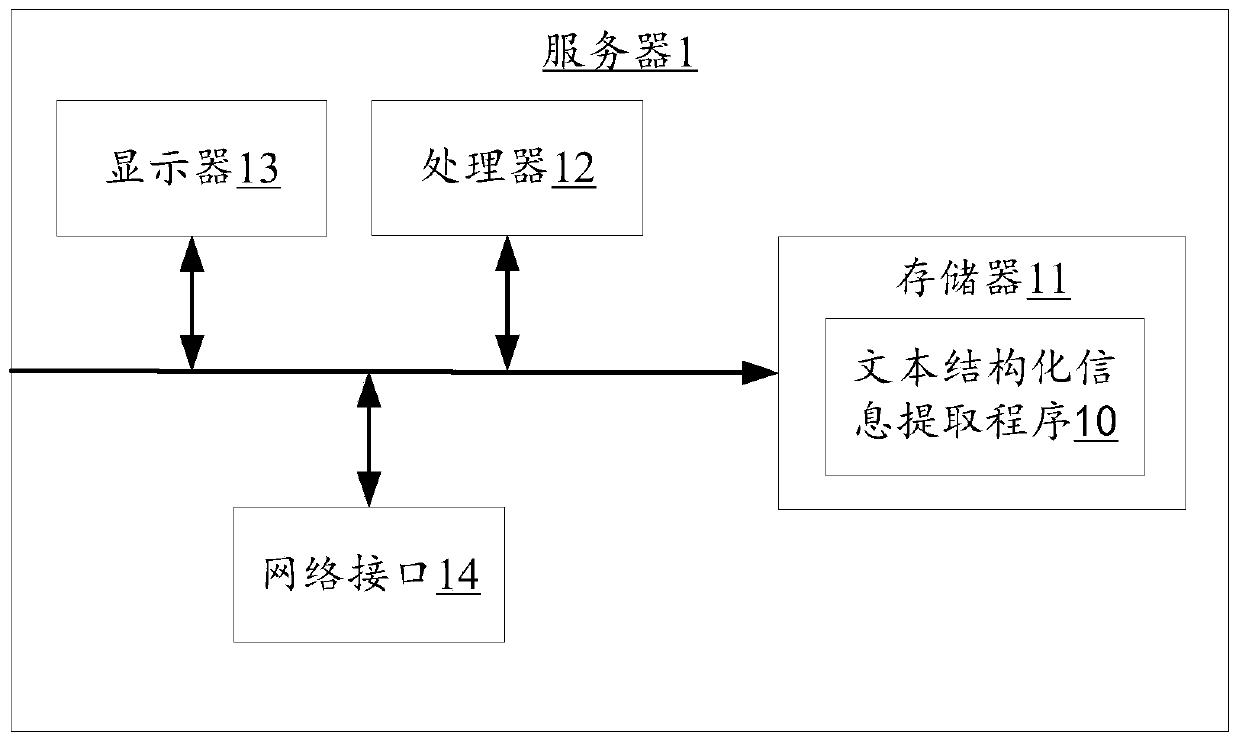

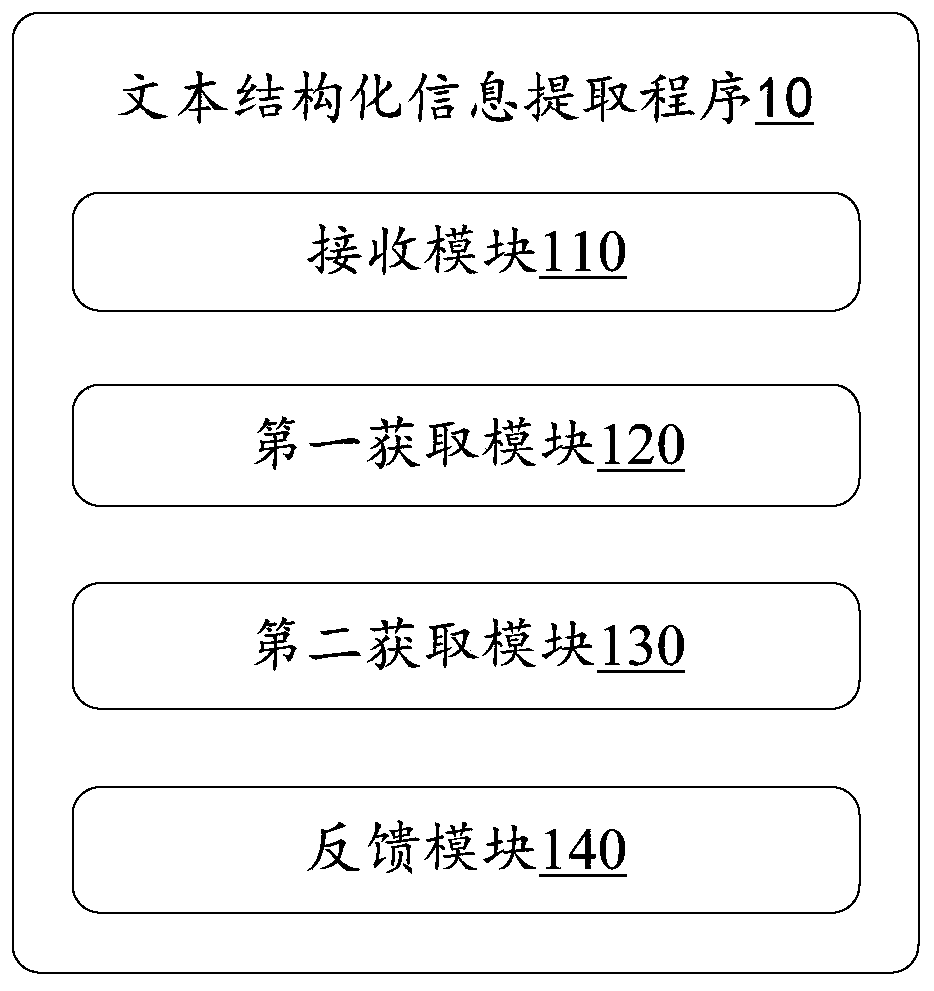

Text structured information extraction method, server and storage medium

PendingCN110287785AImplement extractionAvoid manual processingCharacter and pattern recognitionSpecial data processing applicationsDocumentationWorld Wide Web

The invention relates to a data processing technology, and provides a text structured information extraction method, a server and a storage medium. The method comprises the following steps: firstly, obtaining an original document of to-be-extracted structured information, inputting the original document into a trained first segmentation model to obtain a plurality of first-level tags of the original document, and obtaining first-level text contents corresponding to the first-level tags according to a first preset rule; and then inputting each first-level text content into the trained second segmentation model to obtain a plurality of second-level tags, then obtaining second-level text contents corresponding to each second-level tag according to a second preset rule, storing each obtained tag and text content as logic pages in a preset database, and generating corresponding files to feed back the files to the client. Each first-level tag and each second-level tag in the original document are determined by utilizing the segmentation model, then the structural information is extracted according to the tag content, the extraction of the structured information of the document is automatically realized, and the method is convenient and efficient.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

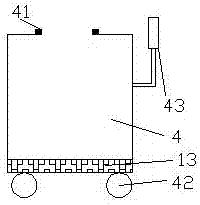

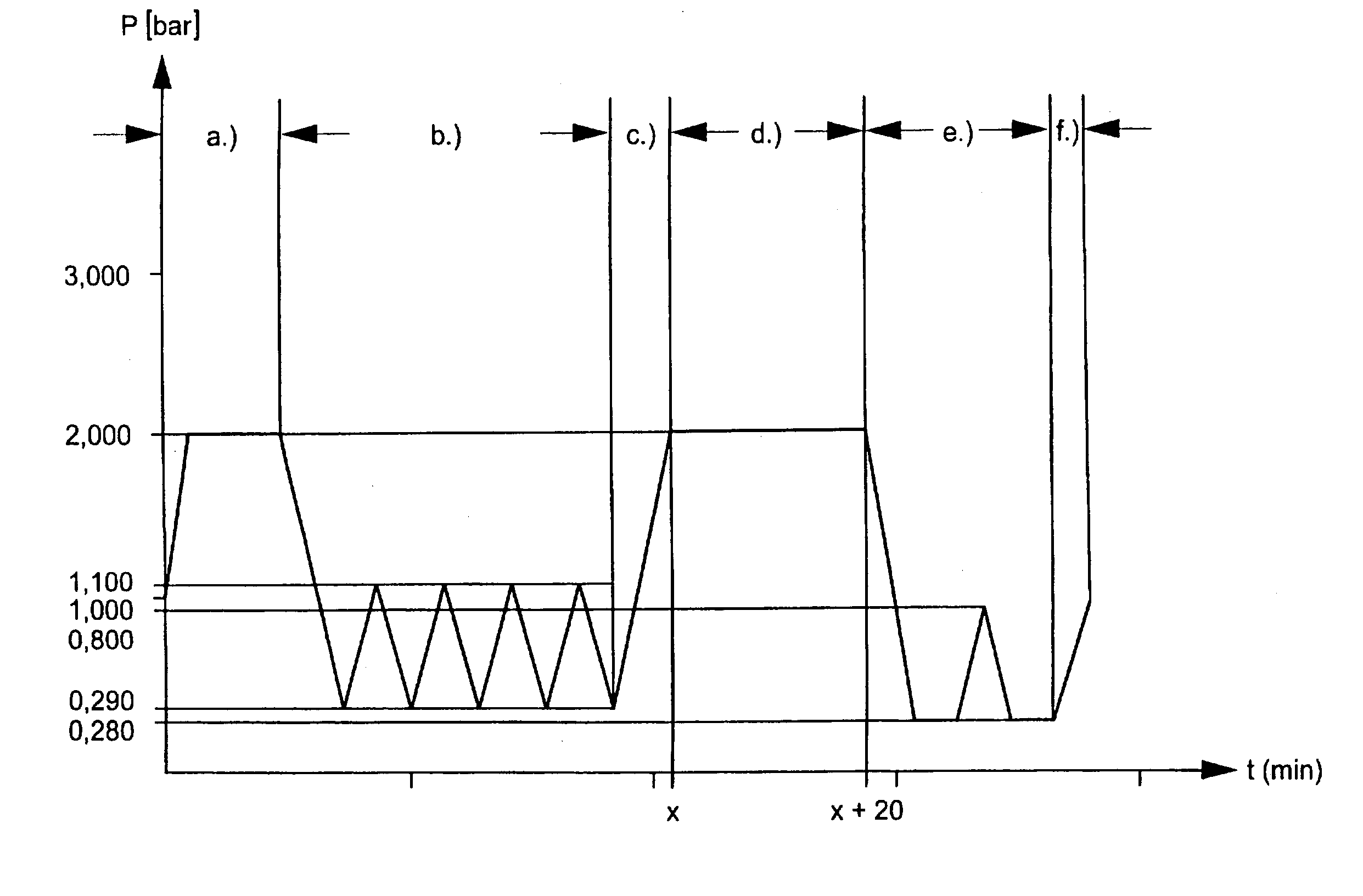

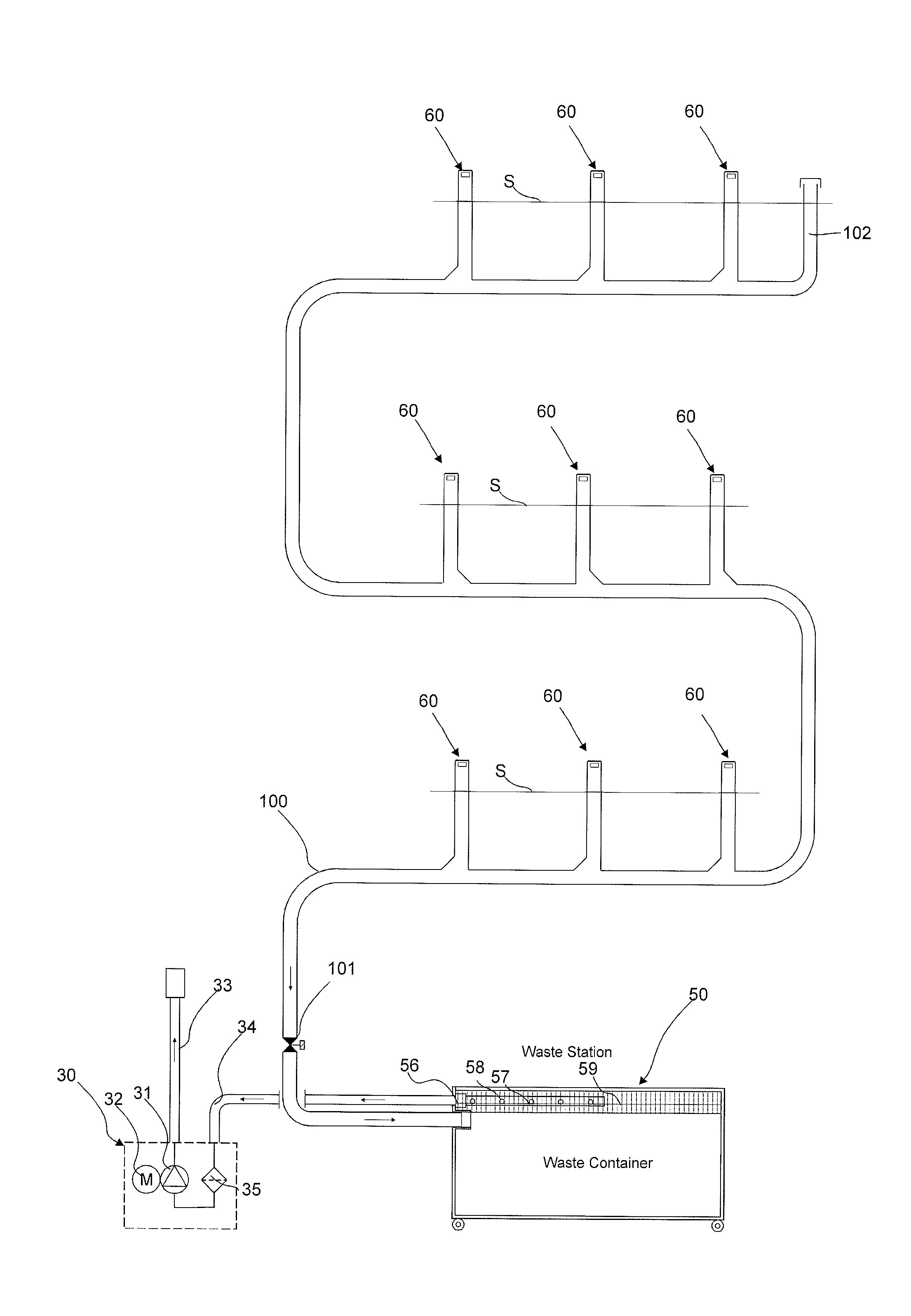

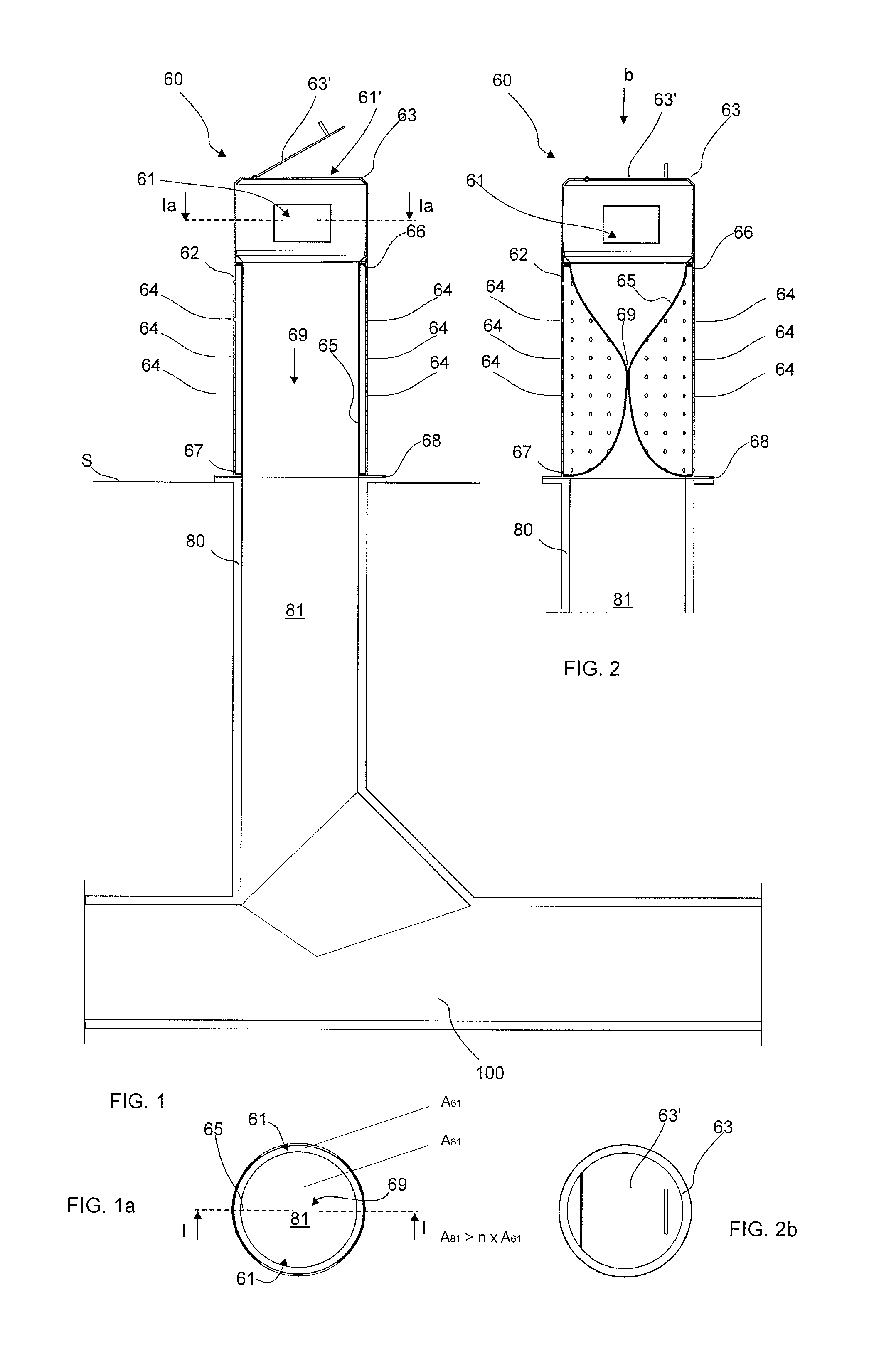

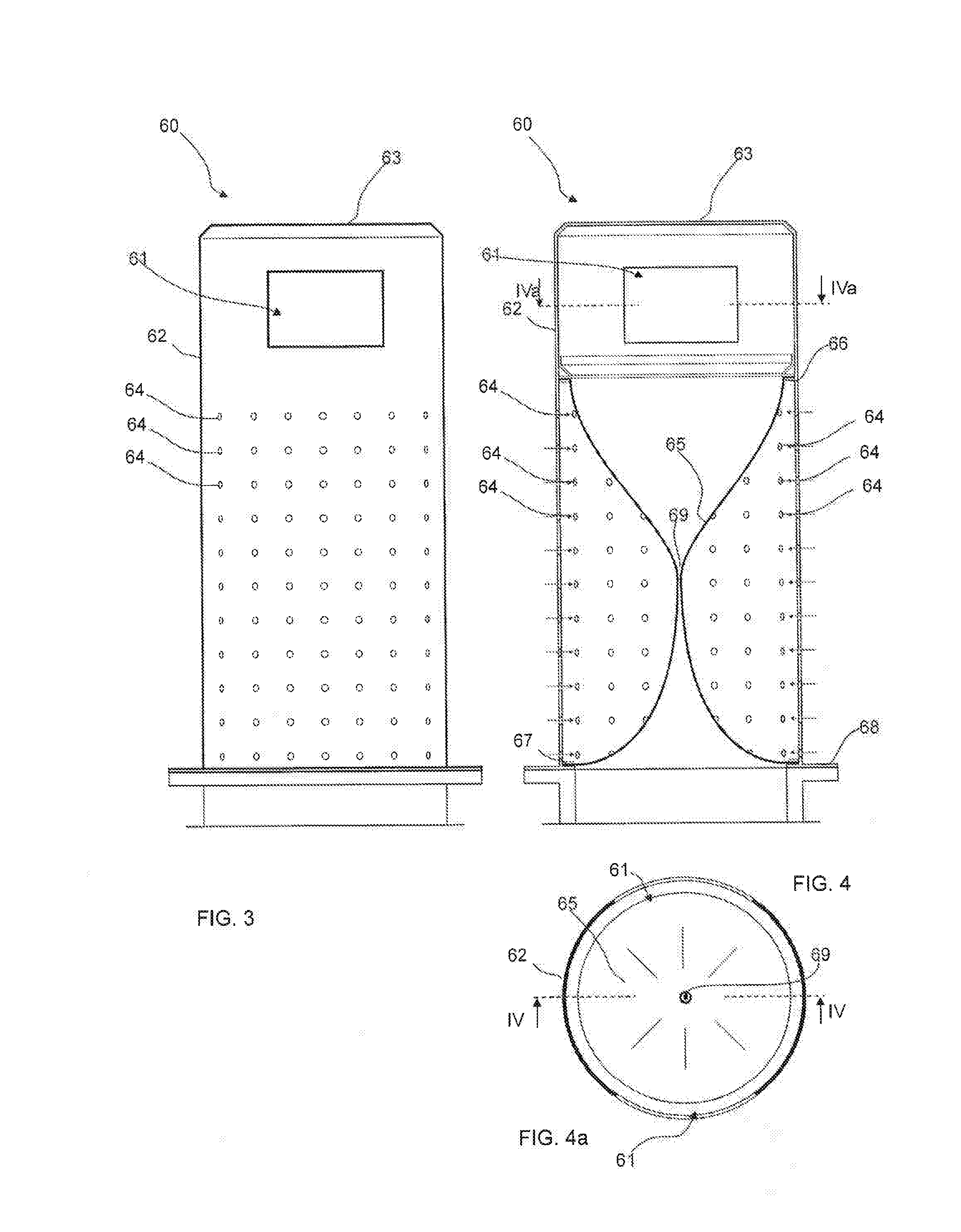

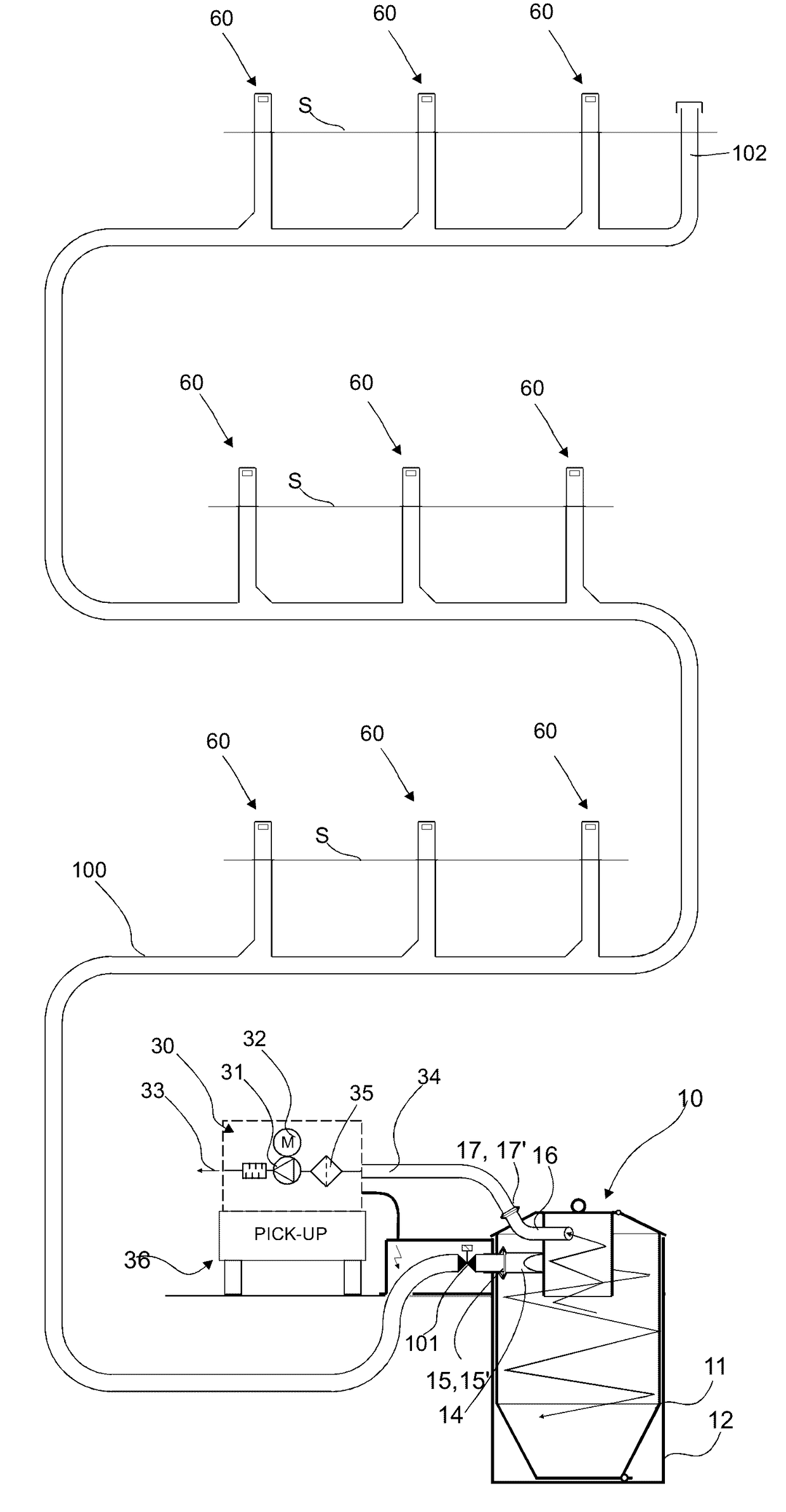

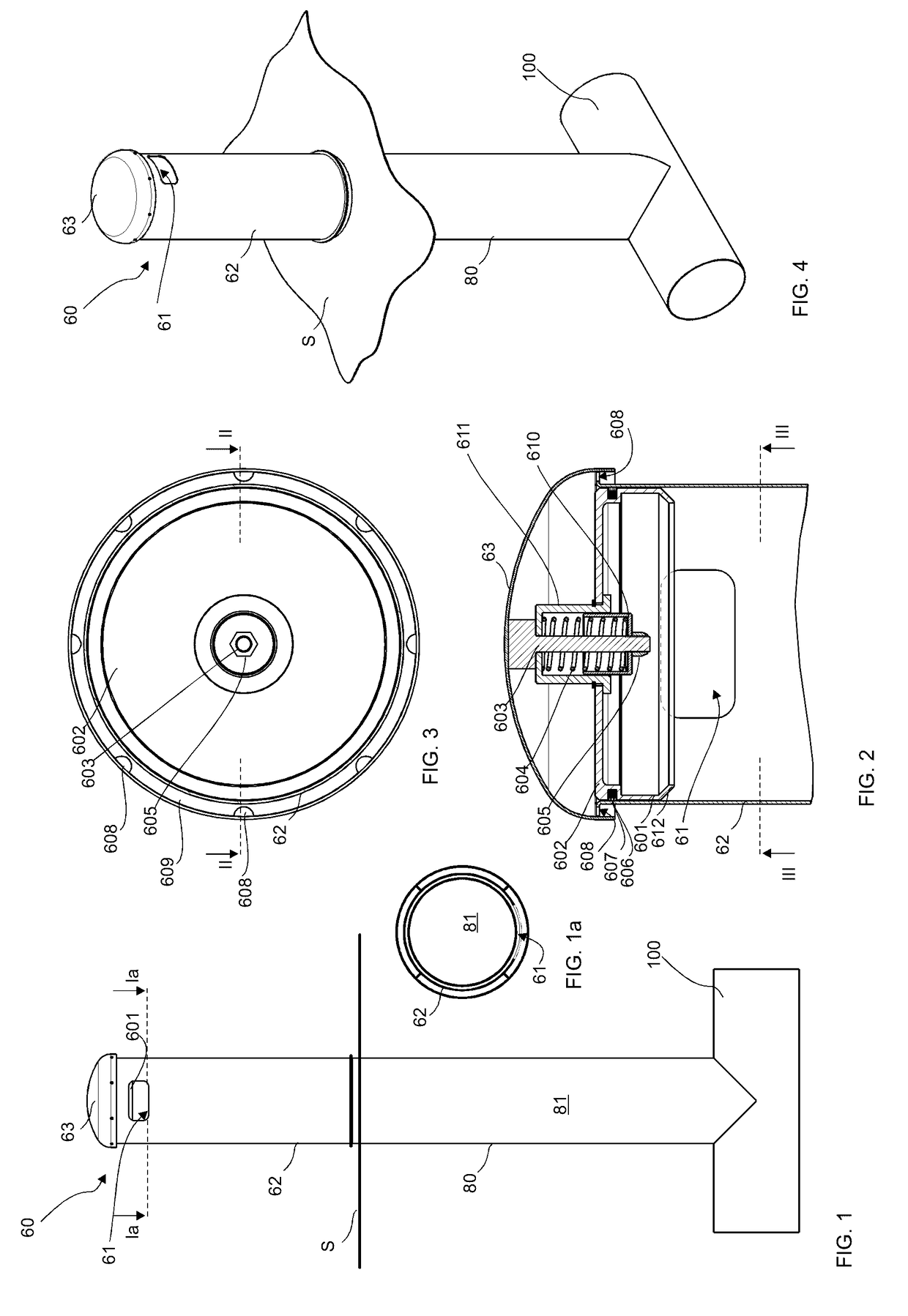

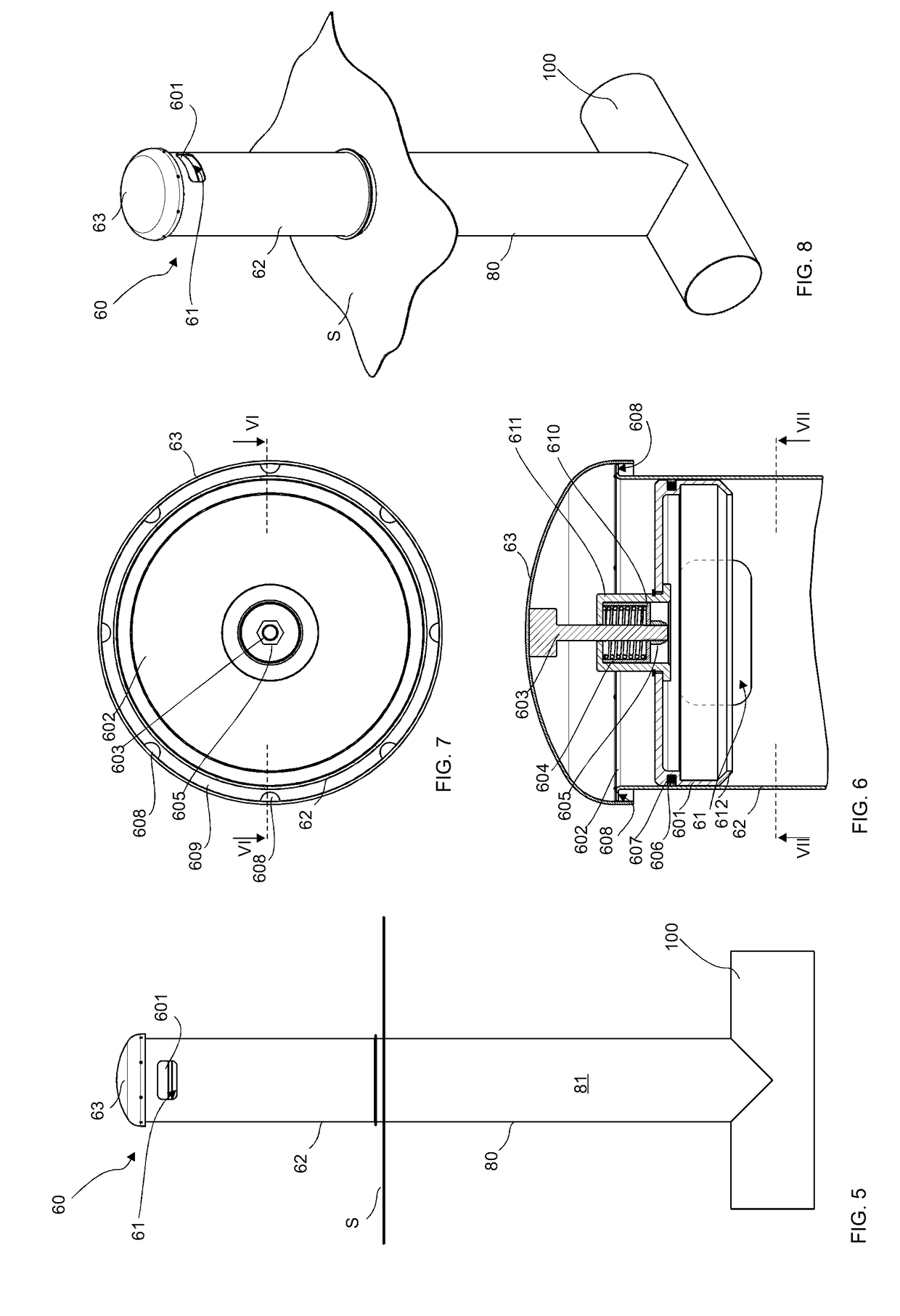

Method for handling material in a material conveying system, input point of a material conveying system, and a material conveying system

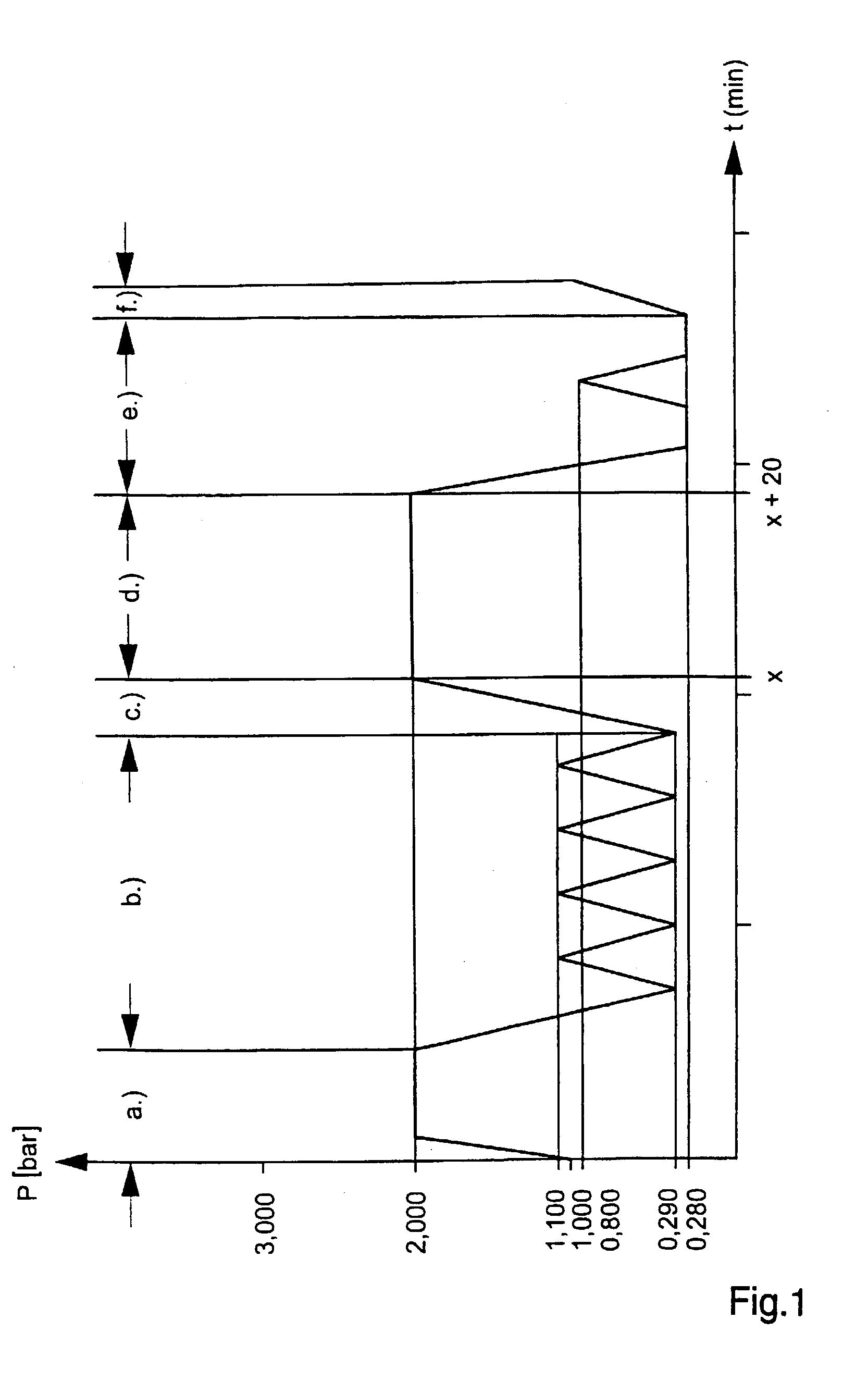

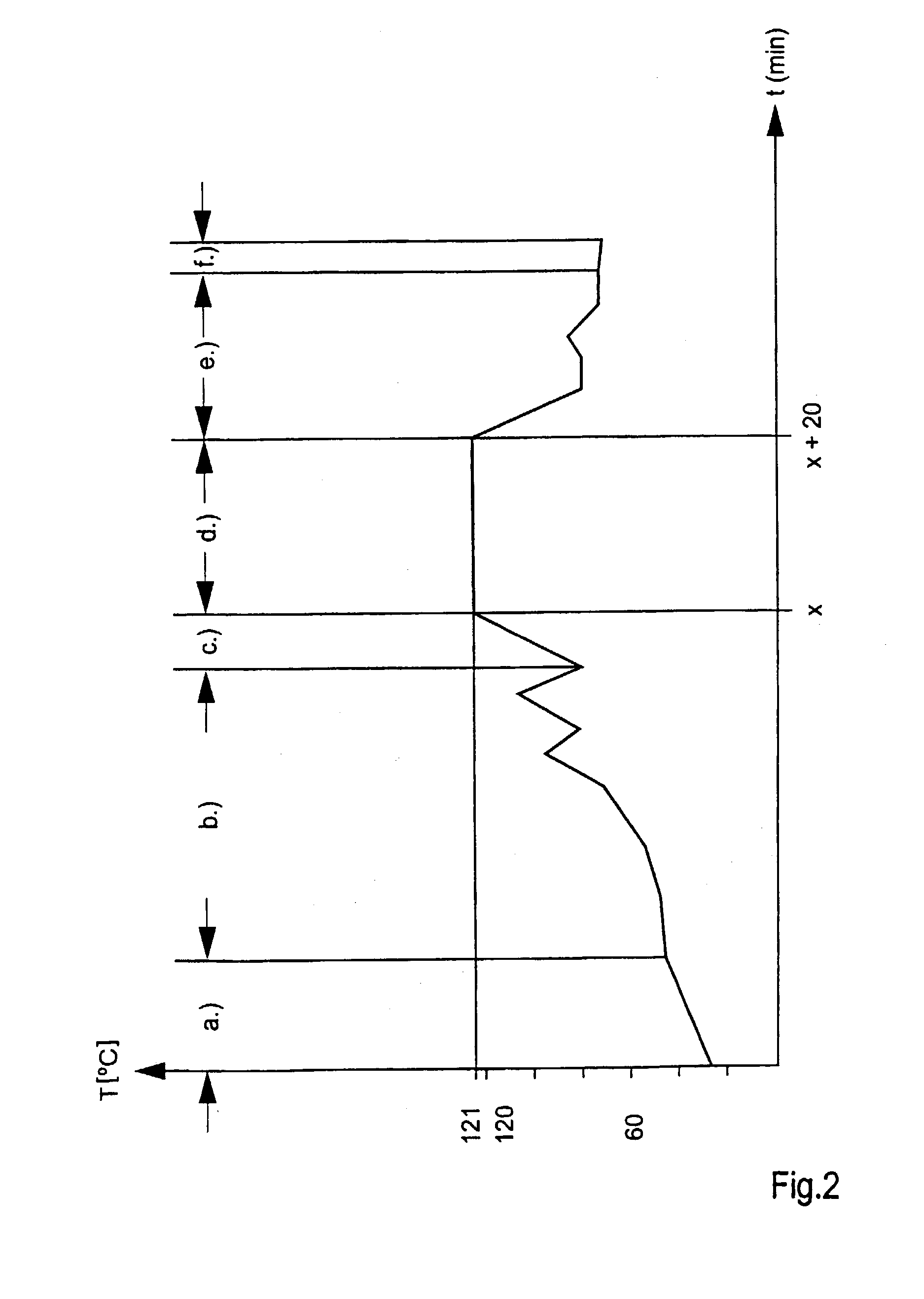

InactiveUS20150274419A1Efficient managementEffective and structurally simple solutionDiaphragm valvesEngine diaphragmsEngineeringPressure difference

Method for feeding and transporting material in a pneumatic material conveying system includes an input point connected to a material conveying pipe and a material container, wherein the material to be transported is separated from the transporting air. A partial vacuum / pressure difference and / or a transporting air flow is achieved in the conveying pipe at least during the transporting of material. The suction side of the partial-vacuum source is connected to the conveying pipe and onwards to an input point arranged in the conveying pipe or at least to the feed-in channel that is between the conveying pipe and an input point, wherein the input point, or at least the feed-in channel, that is closest to the material container in the conveying direction of the material empties and the material displaces into the conveying pipe. A wall for closing the pathway between an input aperture and the conveying pipe is provided.

Owner:MARICAP OY

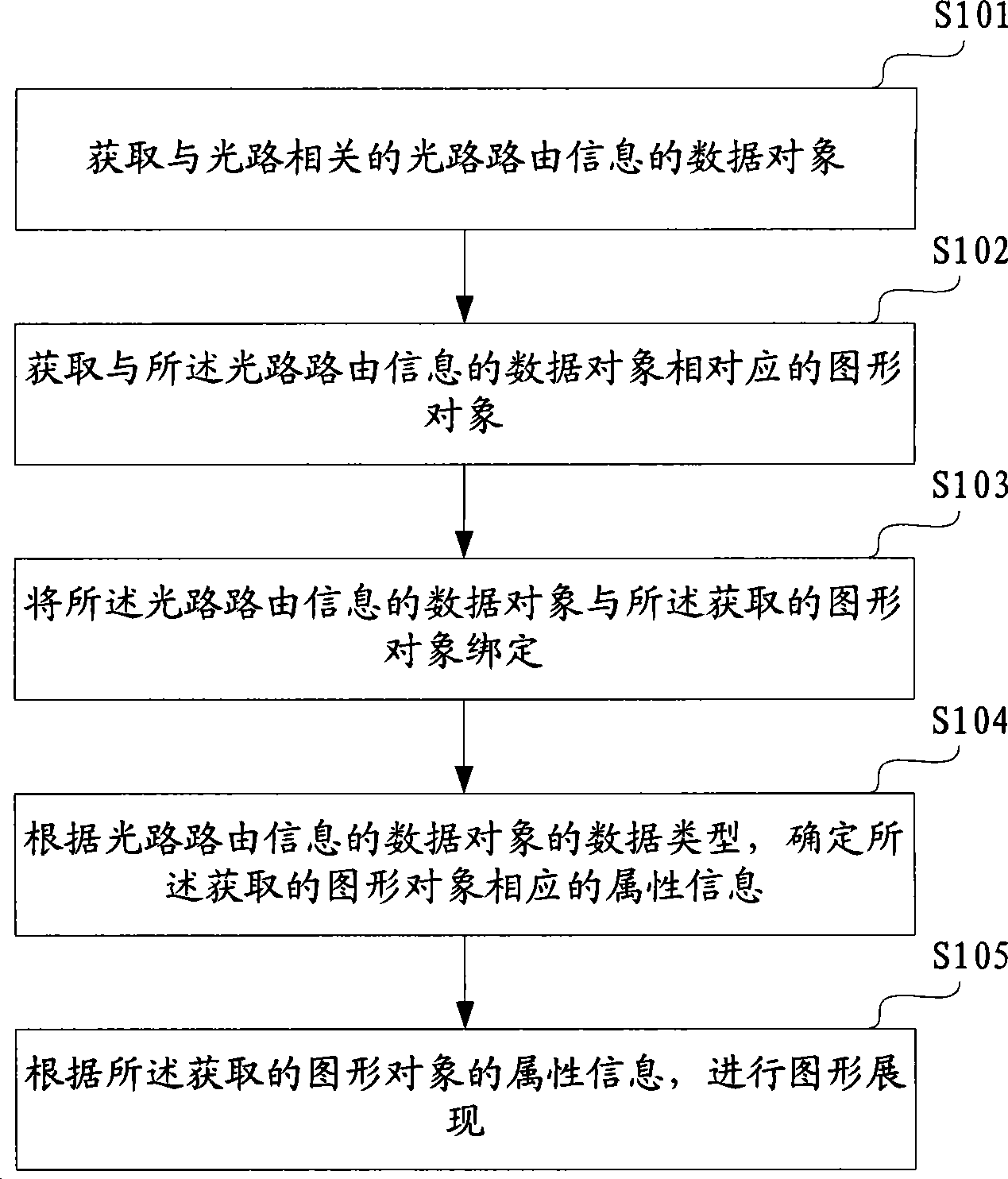

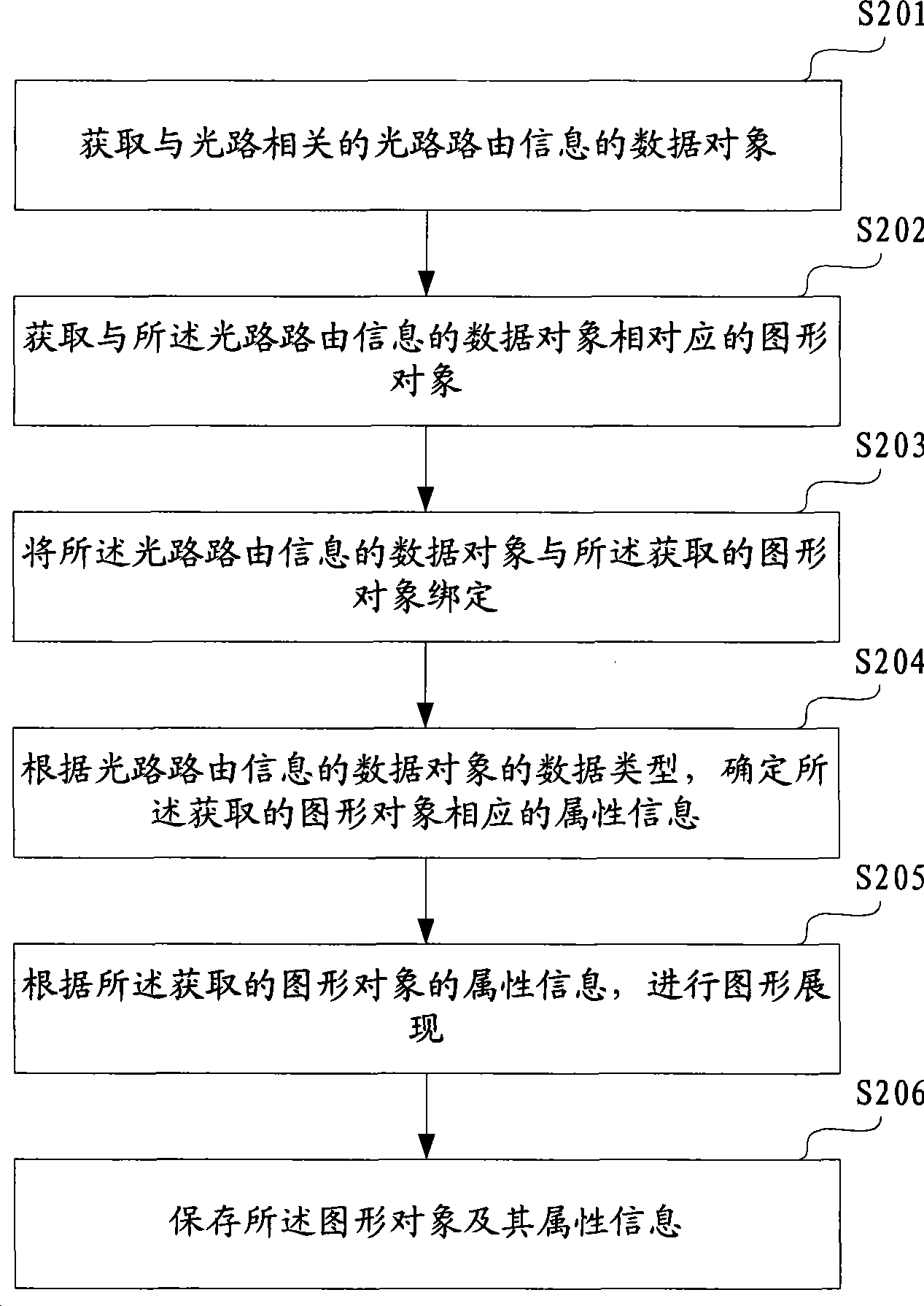

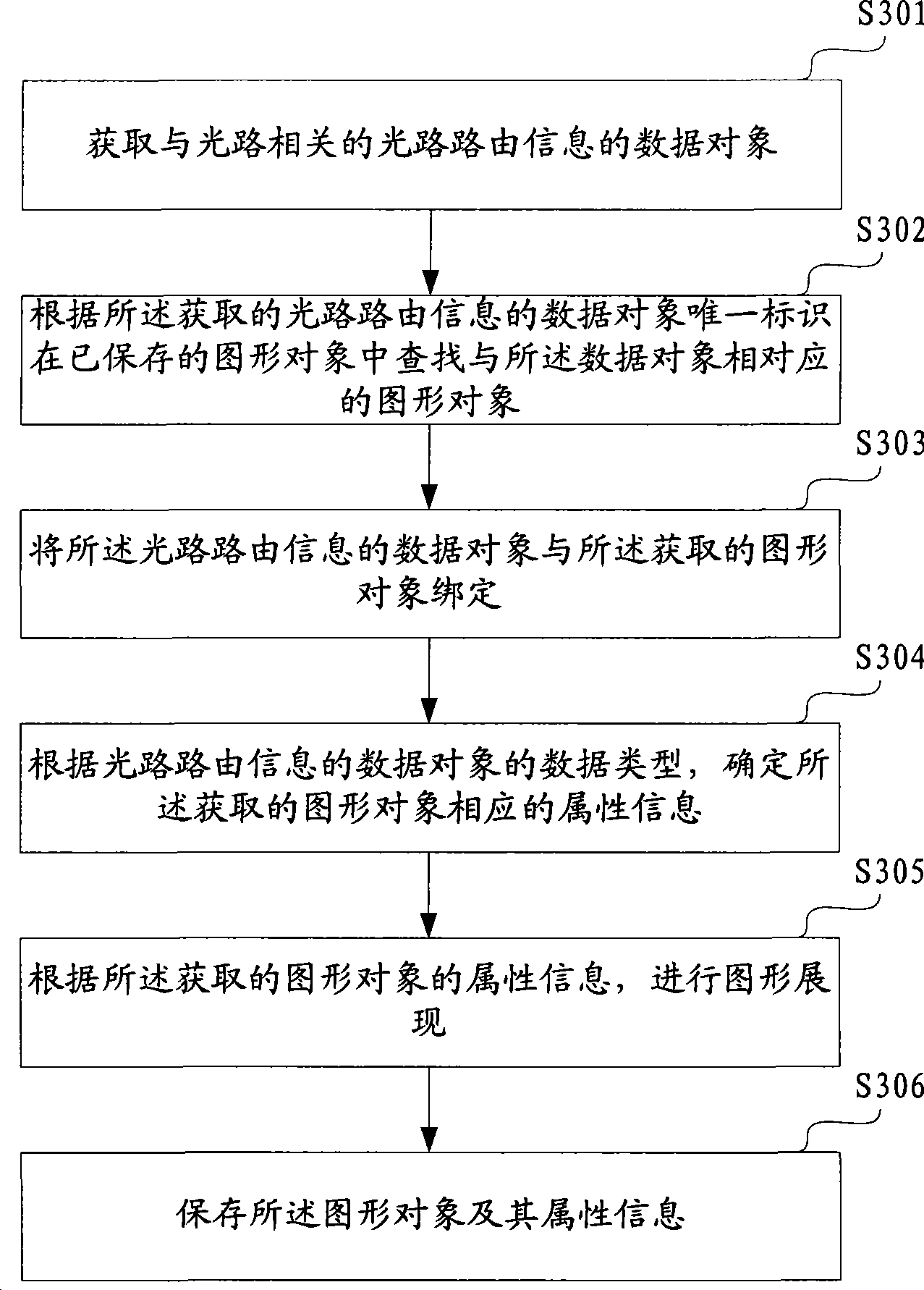

Method and apparatus for revealing light path design graph

ActiveCN101442363AImprove accuracyAvoid manual processingTransmission monitoring/testing/fault-measurement systemsSpecial data processing applicationsGraphicsData type

The invention discloses a method for exhibiting a design graph of a light path, which comprises the following steps: a data object of light path routing information related to the light path is obtained, a graphic object corresponding to the data object of the light path routing information is obtained, the data object of the light path routing information is bound with the obtained graphic object, the attribute information corresponding to the obtained graphic object is determined according to the data type of the data object of the light path routing information, and the graphic exhibition is performed according to the attribute information of the obtained graphic object. The invention also discloses a device for exhibiting the design graph of the light path, which is used for finishing the method. The method finally obtains the graphic object corresponding to the data object of the light path routing information according to the data object of the light path routing information, realizes the graphic exhibition of light path routing, improves the accuracy of the design of the light path, ensures that the design of the light path is simple, real-time, quick and convenient, and is easy to save and maintain a design result.

Owner:BEIJING BOCO COMM TECH

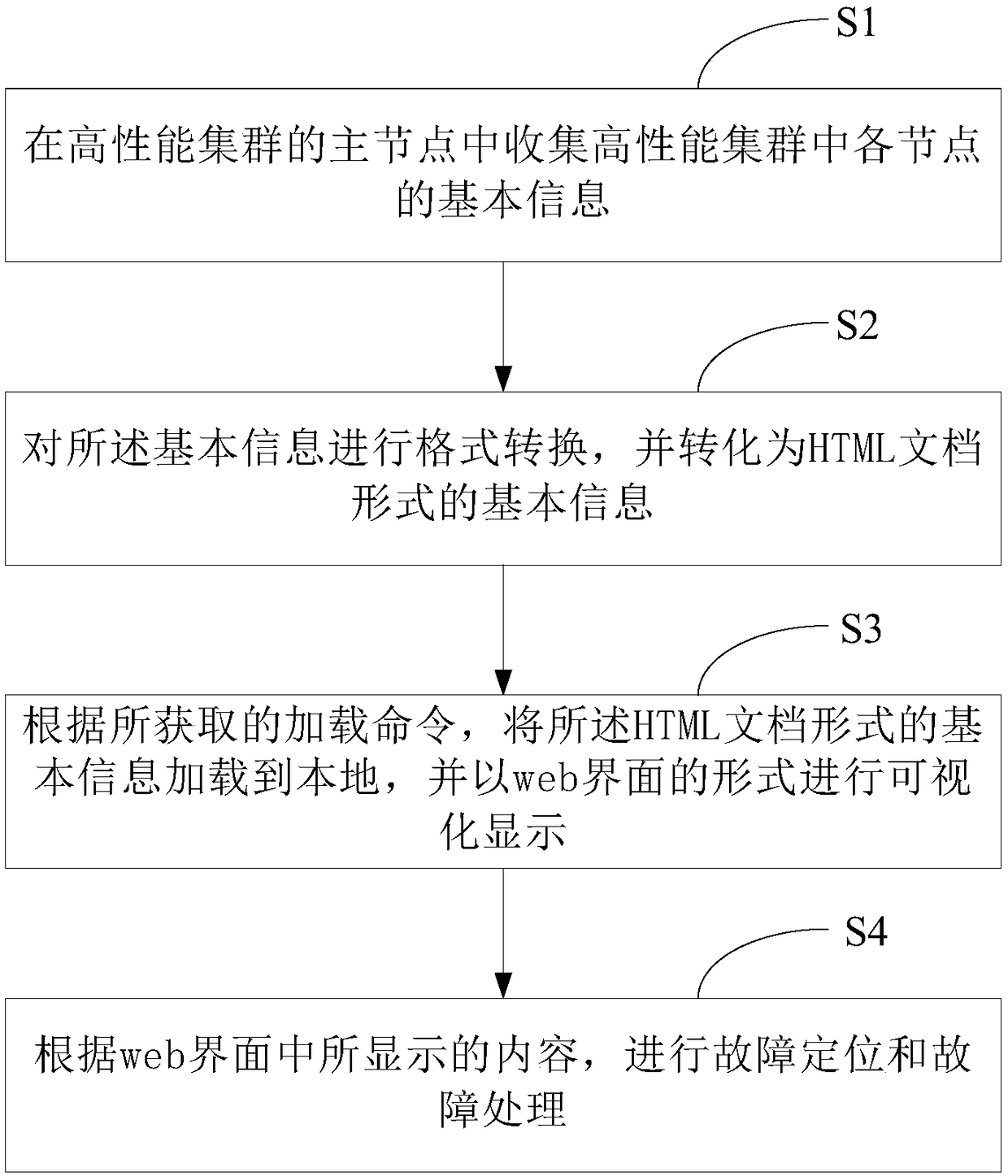

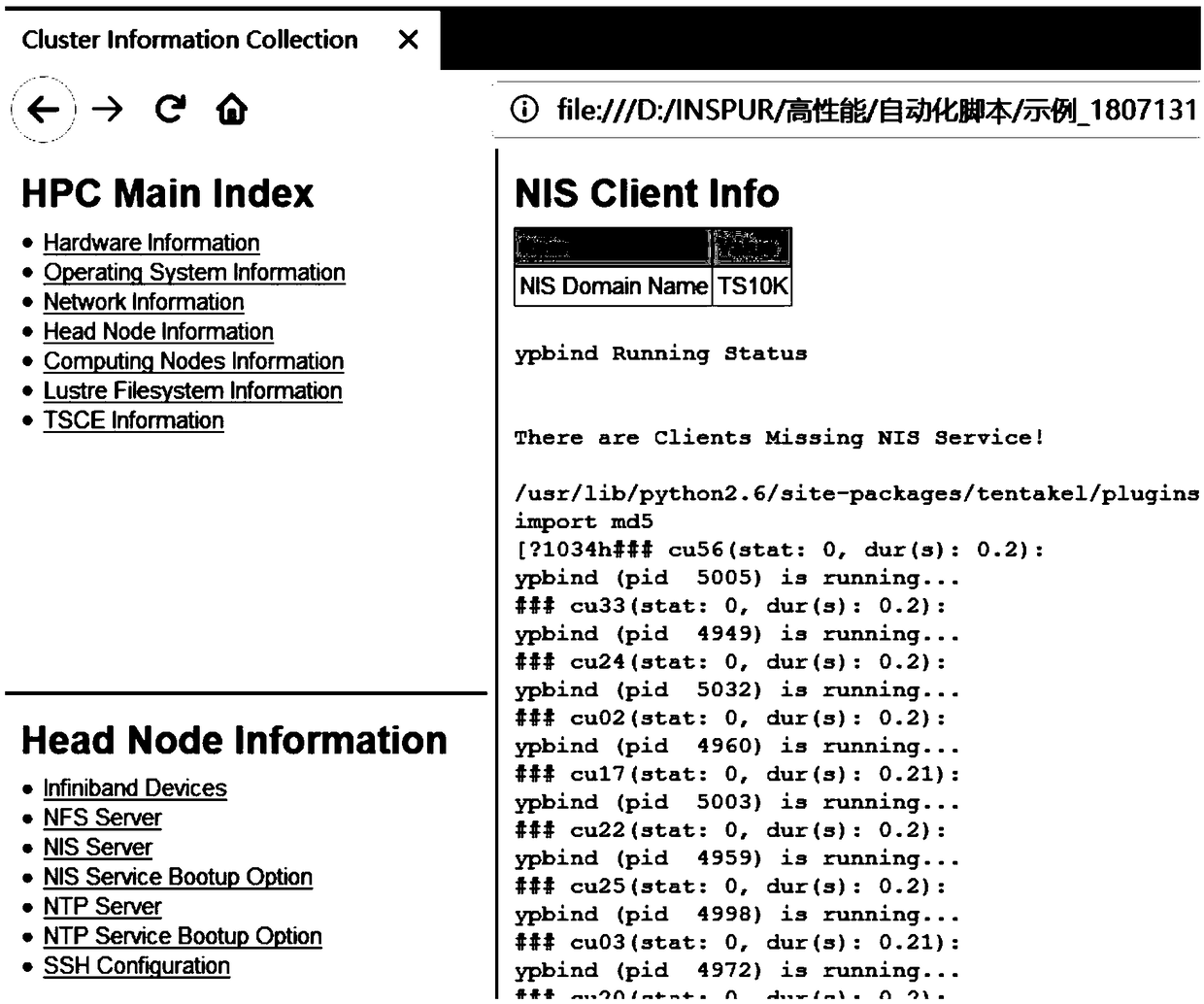

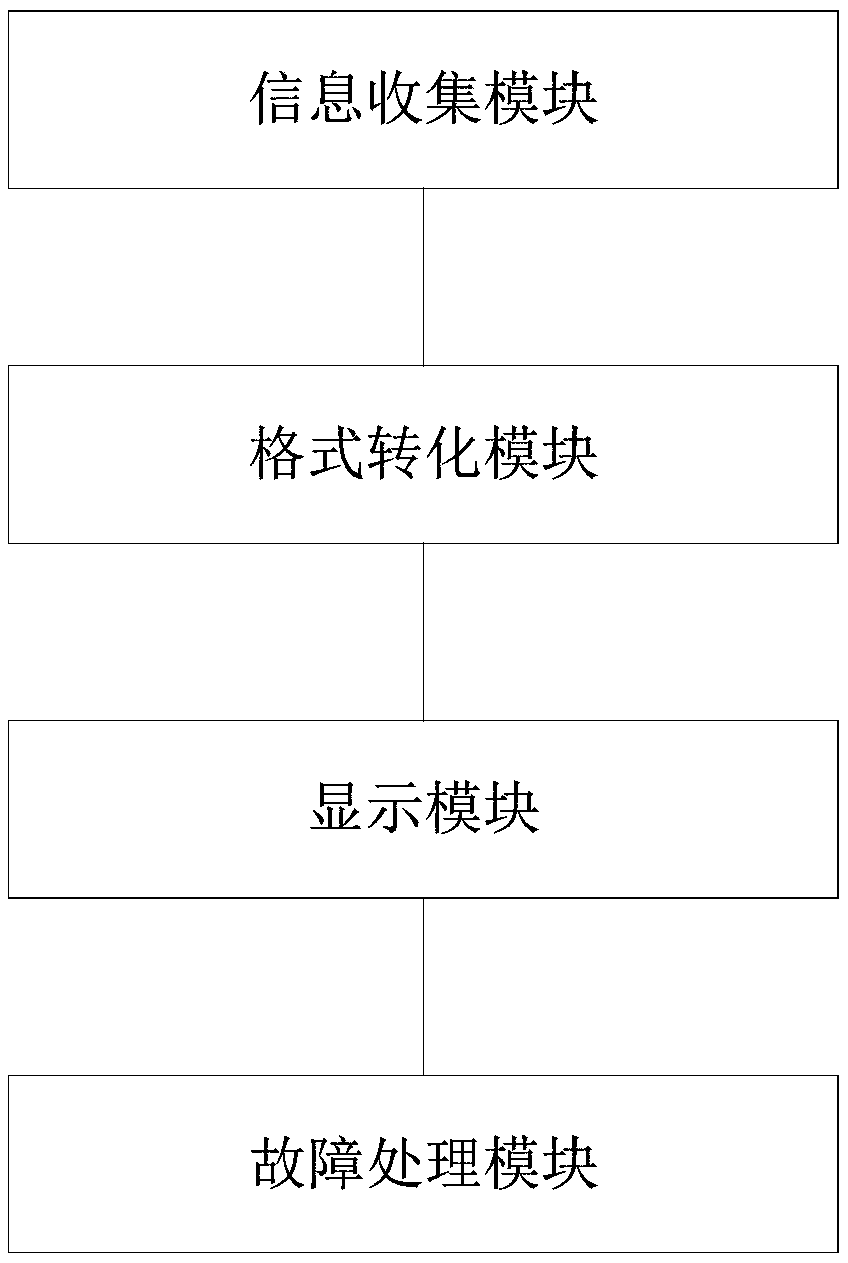

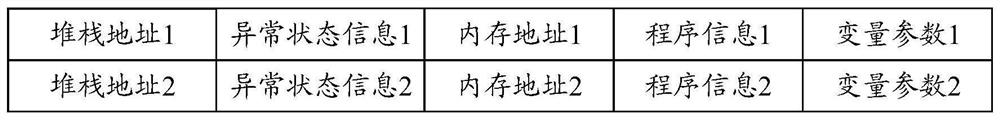

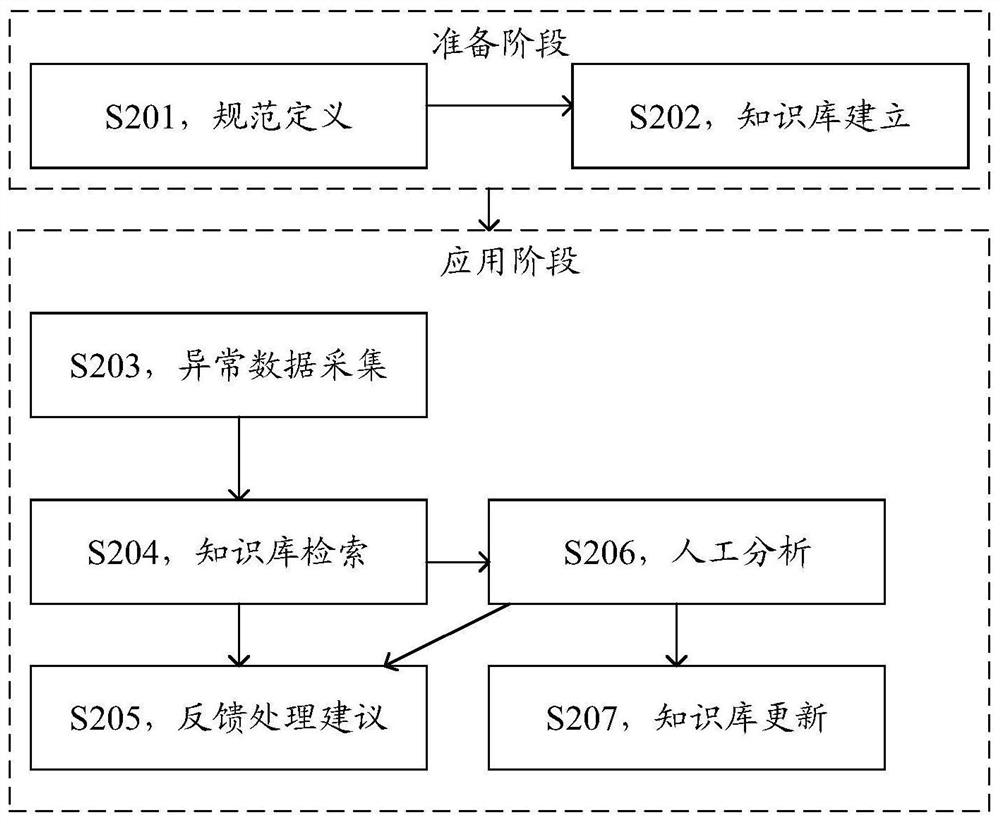

A method and system for fault diagnosis of high-performance cluster

InactiveCN109167676ARapid positioningVisual inspectionData switching networksDiagnosis methodsSoftware engineering

The present application discloses a method and a system for fault diagnosis of a high-performance cluster. The diagnosis method includes: collecting basic information of each node in the high-performance cluster in a master node of the high-performance cluster; converting the basic information into HTML document format; according to the obtained loading command, loading the basic information in the form of HTML document locally and displayed visually in the form of web interface. According to the contents displayed in the web interface, fault location and fault handling are carried out. The diagnostic system includes: an information collection module, a format conversion module, a display module and a fault processing module. The application adopts script to collect, transform and visuallydisplay the basic information of each node in the high-performance cluster, so that the user can very directly view the status of the high-performance cluster, thereby facilitating the fast positioning of the fault point, and effectively improving the accuracy and efficiency of the fault troubleshooting.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

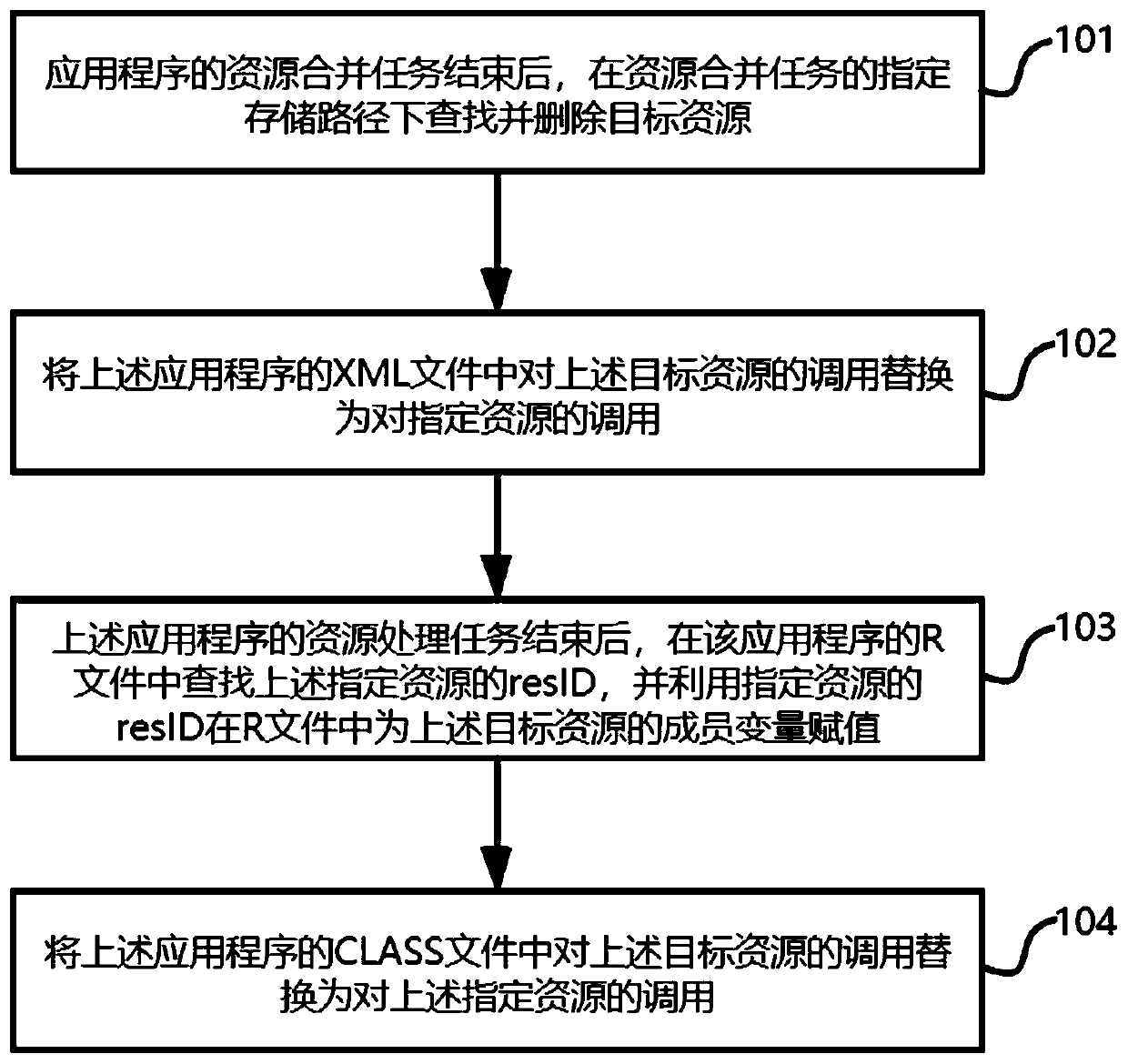

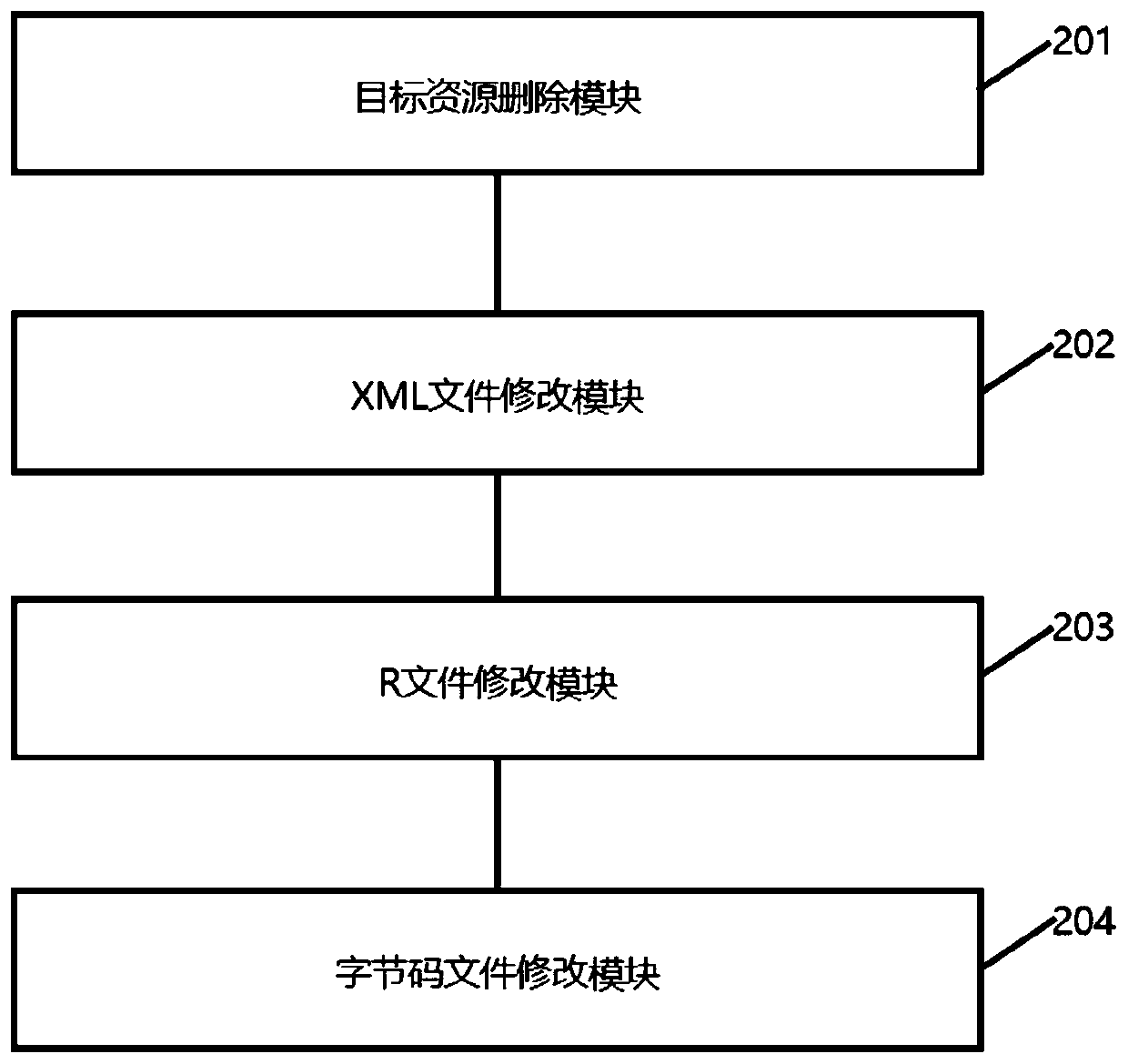

Resource processing method and device of application program, equipment and storage medium

PendingCN111290738AFull searchExact searchSoftware designFile metadata searchingPathPingApplication procedure

The embodiment of the invention provides a resource processing method and device of an application program, equipment and a storage medium. The method comprises the following steps: after a resource merging task is finished, searching and deleting a target resource under a first specified storage path of the resource merging task; replacing the calling of the target resource in the XML file with the calling of the specified resource; after the resource processing task is finished, searching a resource identifier of a specified resource in the R file, and assigning a value to a member variableof the target resource in the R file by utilizing the resource identifier of the specified resource; and replacing the calling of the target resource in the byte code file with the calling of the specified resource. According to the method, in the packaging process of the application program, the resources are automatically processed, and the resource processing efficiency is improved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Packing auger control device and method

PendingCN110654787AReduce resistanceAvoid manual processingConveyorsControl devices for conveyorsPhysicsAutomatic processing

The invention provides a packing auger control device and method, and relates to the technical field of engineering machines. The packing auger control device comprises a rotating speed sensor, a torque detecting mechanism, a controller and a driving mechanism. The rotating speed sensor is used for detecting the rotating speed data of a packing auger and transmitting the rotating speed data to thecontroller. The torque detecting mechanism is used for detecting the torque output numerical value of the driving mechanism and transmitting the torque output numerical value to the controller. Whenthe packing auger stops rotating and the torque output numerical value is larger than an output preset value, the controller controls the driving mechanism to drive the packing auger in the reverse direction. When the packing auger stops rotating and the torque output numerical value of the driving mechanism is larger than an output preset value, the controller controls the driving mechanism to drive the packing auger to rotate in the reverser direction, so that a clearance is generated between a conveyed propping agent and the packing auger, resistance is reduced, and the locking problem of the packing auger is handled. It shows that by means of the arrangement, the locking problem can be automatically handled when the packing auger is locked, manual handling of a user is avoided, and theautomation degree is improved.

Owner:三一石油智能装备有限公司

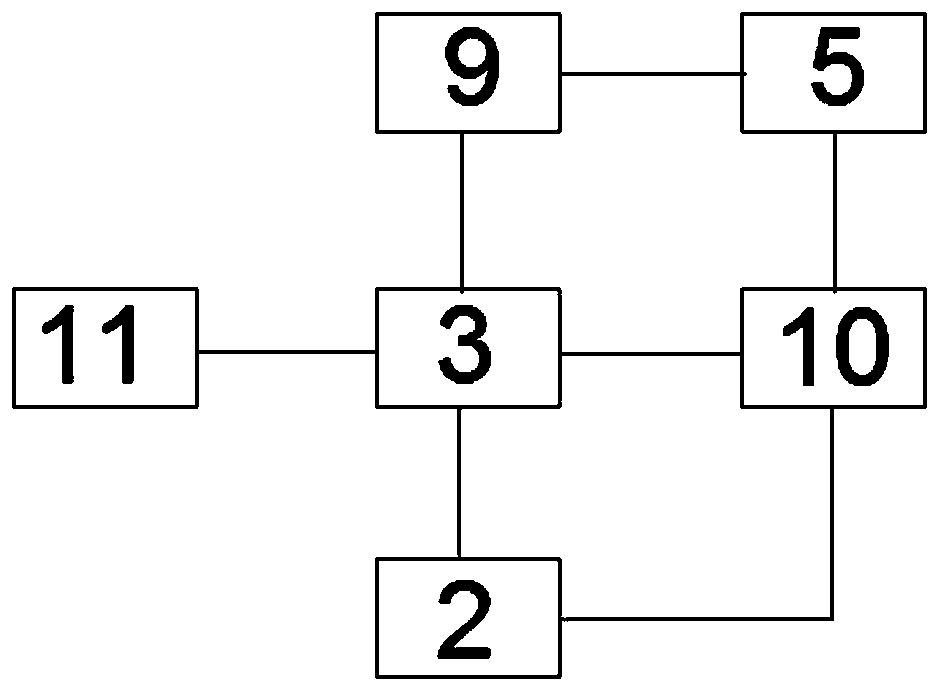

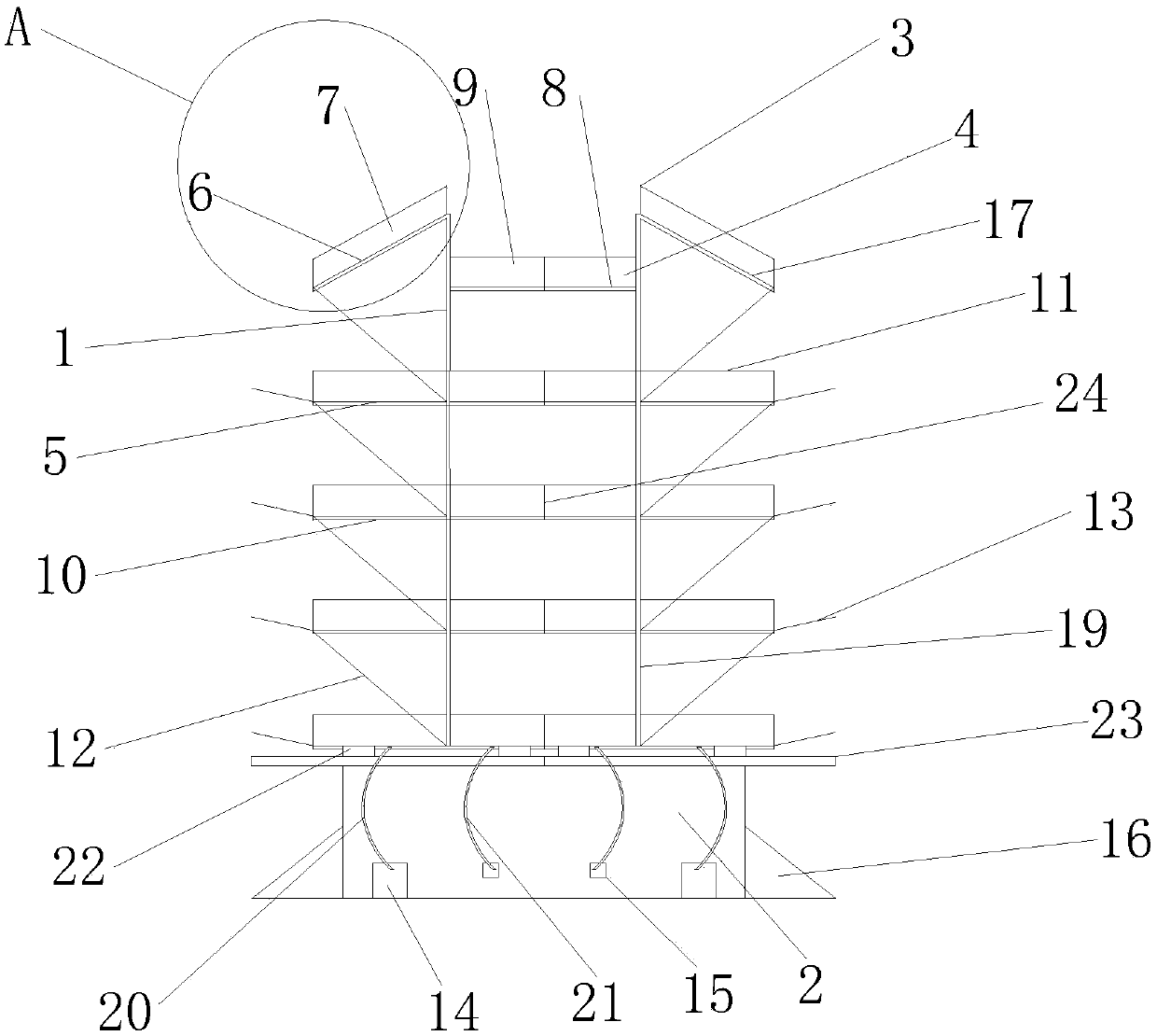

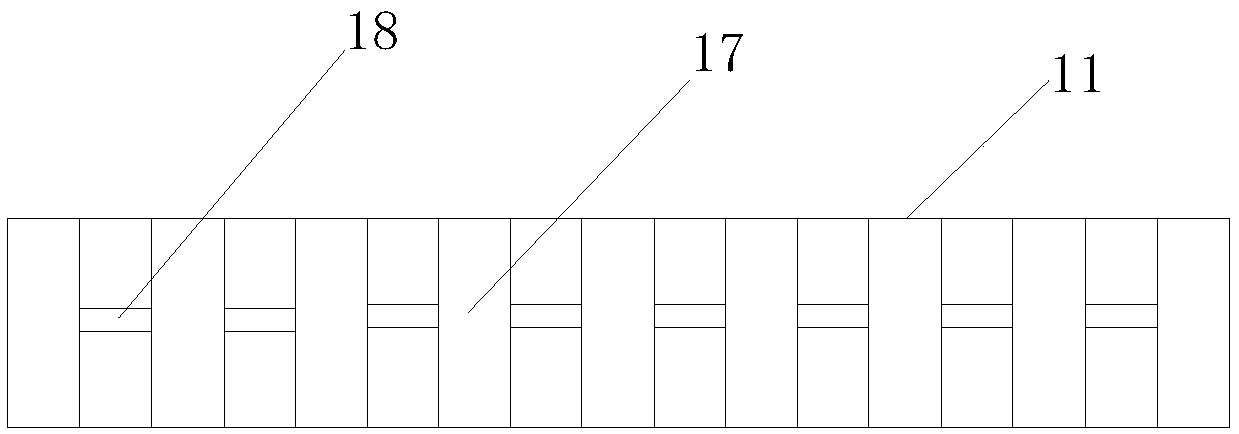

Stereoscopic strawberry planting device and cultivation method

InactiveCN109526455ASolve lighting needsAvoid manual processingSelf-acting watering devicesSaving energy measuresWater bathsAgricultural engineering

The invention relates to the technical field of crop planting and discloses a stereoscopic strawberry planting device. The stereoscopic strawberry planting device comprises a main supporting column and a water bath, wherein an upper tank rack, an upper substrate tank, a middle tank rack, a middle substrate tank, a lower tank rack, a lower substrate tank and a support frame are arranged on the mainsupporting column; side reflectors are arranged at two ends of the lower tank rack; a water pump, a control valve and an illuminating apparatus are arranged outside the water bath; water chambers andtransverse water pipes are arranged at the bottoms of the upper substrate tank, the middle substrate tank and the lower substrate tank; a vertical water pipe is arranged on the main supporting column; a water inlet pipe is arranged between the water pump and the water chambers; a water outlet pipe is arranged between the control valve and the water chambers; a slide block and a sliding rail are arranged below the lower tank rack; a reflective surface is respectively arranged at the bottoms of the upper substrate tank, the middle substrate tank, the lower substrate tank and the water chambers.The invention further discloses a stereoscopic cultivation method by utilizing the stereoscopic strawberry planting device. The stereoscopic strawberry planting device disclosed by the invention is simple in structure, high in space utilization efficiency, sufficient in illumination, small in strawberry root transpiration, capable of preserving moisture, ventilating and insulating heat, and highin economic benefits.

Owner:吴晓卫

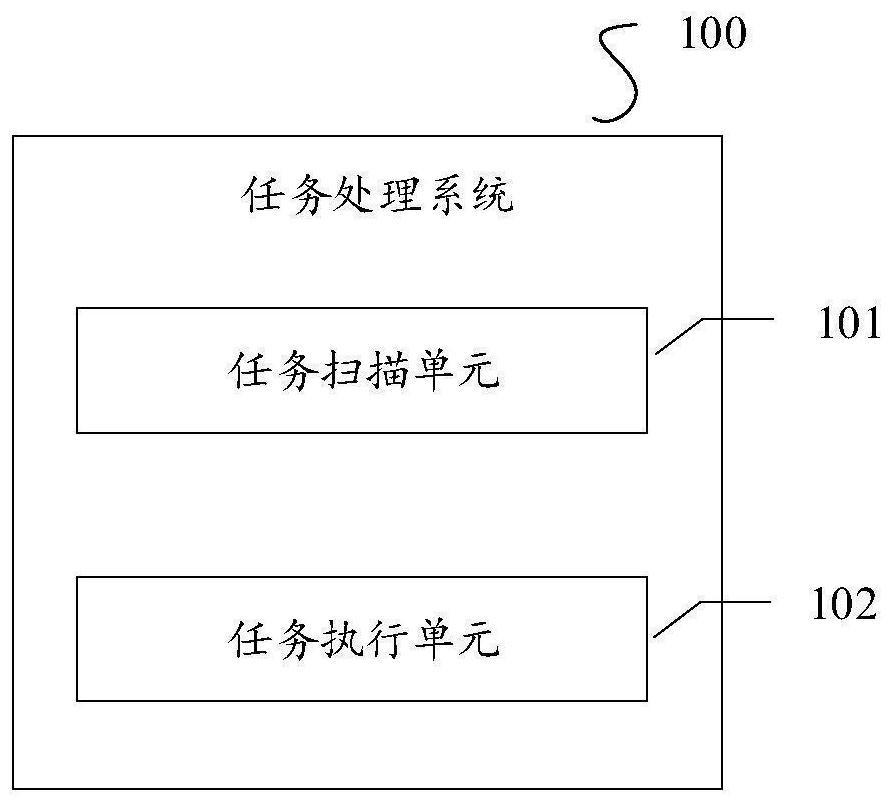

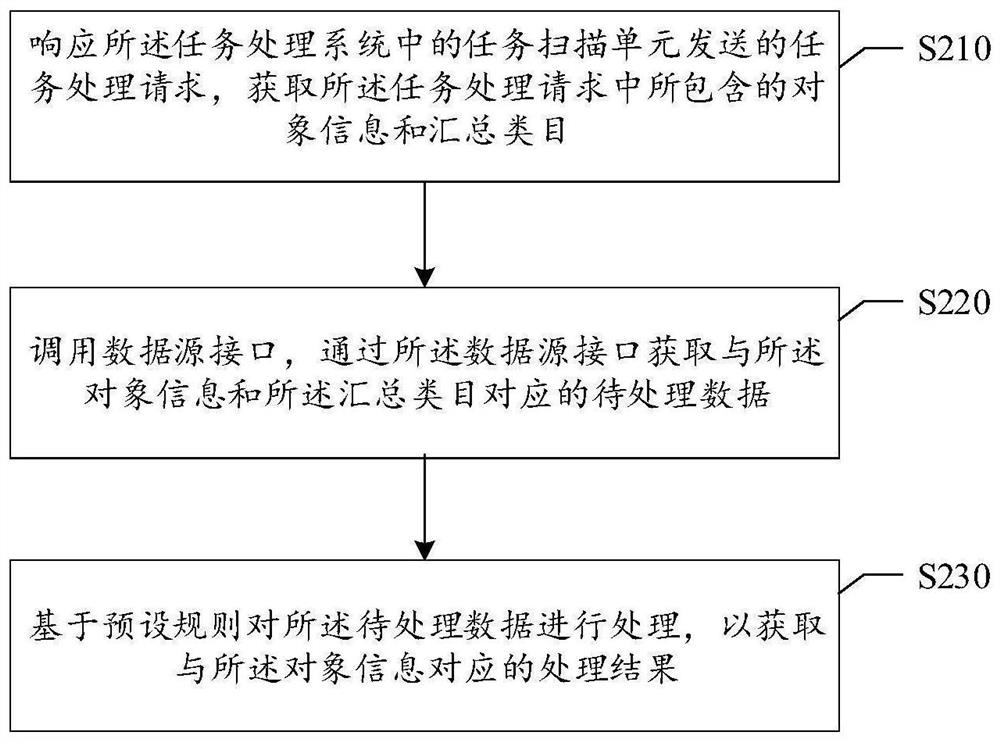

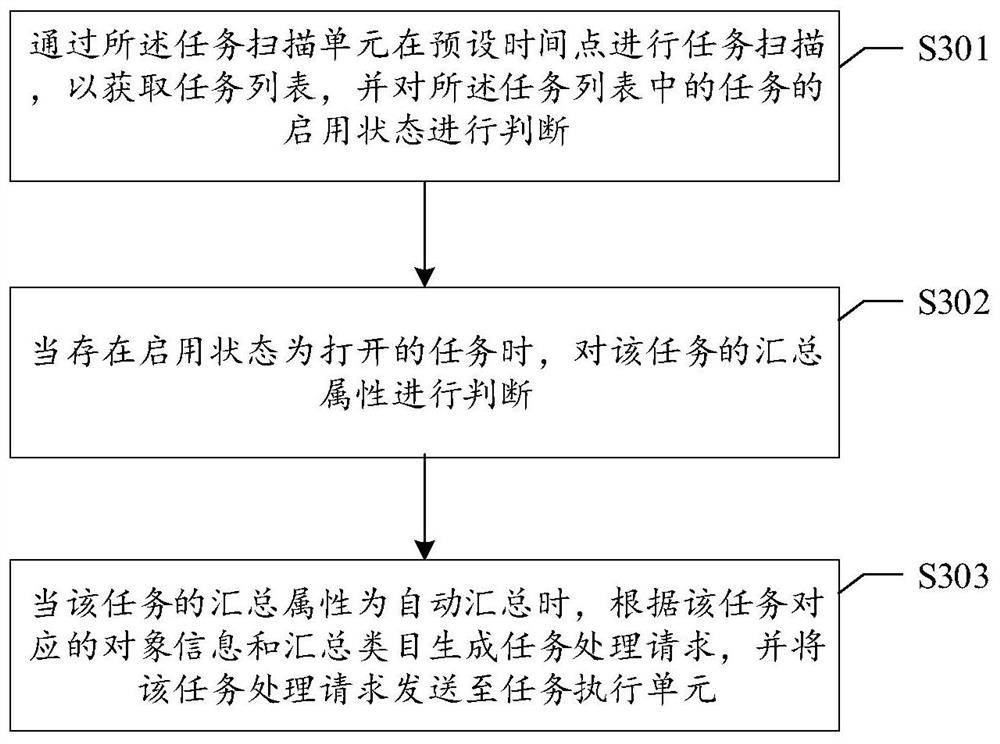

Task processing method, device and system, storage medium and electronic equipment

PendingCN113296912AGuaranteed accuracyAvoid manual processingProgram initiation/switchingResource allocationComputer hardwareData source

The invention relates to the field of computers, and provides a task processing method, device and system, a computer storage medium and electronic equipment.The method is applied to a task execution unit in a task processing system and comprises the steps of responding to a task processing request sent by a task scanning unit in the task processing system; obtaining object information and a summary category contained in the task processing request; calling a data source interface, and obtaining to-be-processed data corresponding to the object information and the summary category through the data source interface; and processing the to-be-processed data based on a preset rule to obtain a processing result corresponding to the object information. On one hand, automatic task processing can be achieved, manual processing is avoided, then the task processing efficiency is improved, and the cost is reduced; On the other hand, manual operations are avoided, the accuracy of information is ensured, and the accuracy of processing results is further improved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

Method for handling material in a material conveying system, an input point of a material conveying system and a material conveying system

ActiveUS20170166409A1Efficiently manageImprove safetyRefuse receptaclesBulk conveyorsAirflowEngineering

A method is provided for feeding in and transporting material in a pneumatic conveying system for material, which conveying system includes at least one input point of material, a material conveying pipe, which can be connected to the input point, and a material container, in which the material being transported is separated from the transporting air, and also a device configured to product a partial vacuum / a pressure difference and / or a transporting air current in the conveying pipe at least during the transporting of the material, which device includes at least one partial-vacuum source. In the method, the suction side of the partial-vacuum source is connected to act in the conveying pipe and onwards to an input point arranged in the conveying pipe, or to act at least in the feeder channel that is between the conveying pipe and the input point, in which case the input point, or at least the feeder channel, intended for emptying that is closest to the material container in the conveying direction of the material empties and the material displaces into the conveying pipe, that arranged in the input point, on the inside of said input point and on the opposite side of the input aperture with respect to the feeder channel, is a shut-off element, which is moved by means of the suction produced by the partial-vacuum source from a first position, in which the shut-off element does not make the pathway through the input aperture into the feeder channel essentially smaller, into a second position, in which the shut-off element does make the pathway through the input aperture into the feeder channel essentially smaller, when the pressure on the first side, on the feeder channel side, of the shut-off element is smaller than on the second side, on the opposite side with respect to the feeder channel, of the shut-off element. An input point and to a pneumatic material-conveying system are also disclosed.

Owner:MARICAP OY

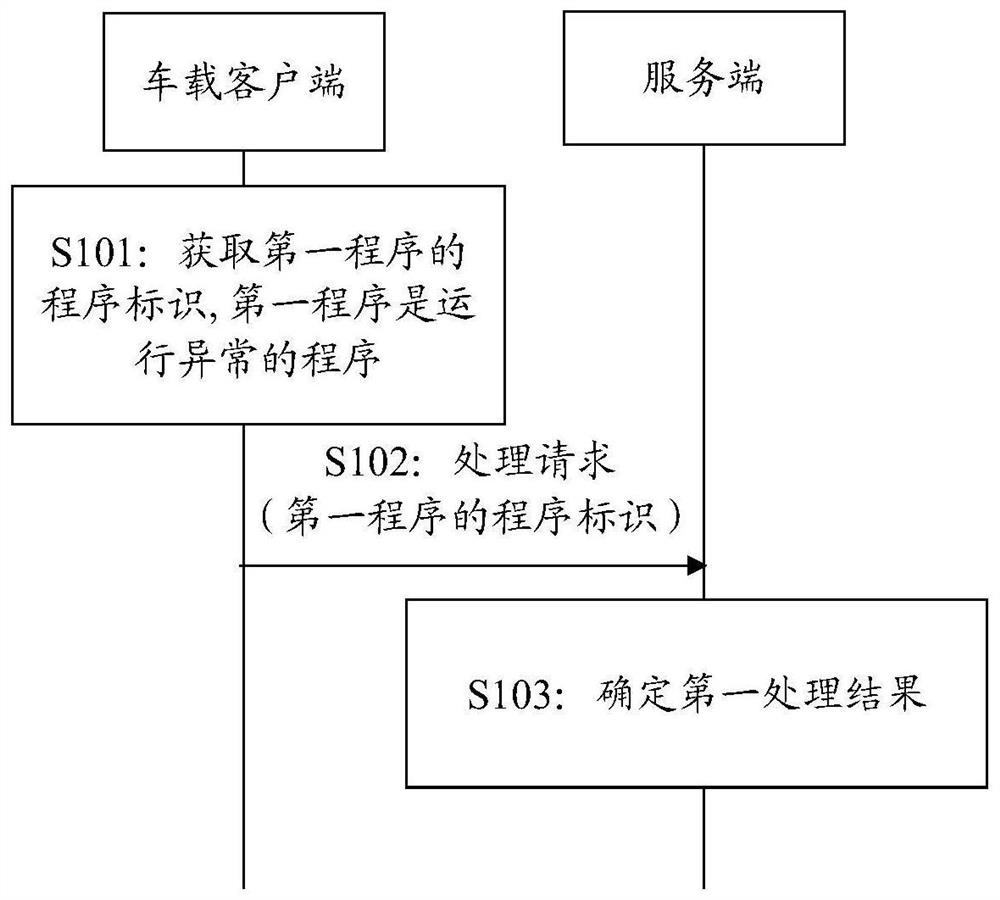

Vehicle-mounted system exception handling method and device

PendingCN112486715AAvoid manual processingReduce labor costsNon-redundant fault processingIn vehicleReal-time computing

The invention provides a vehicle-mounted system exception handling method, which comprises the steps that a vehicle-mounted client acquires a program identifier of a first program, and the first program is a program running abnormally; the vehicle-mounted client sends a processing request to the server, the processing request is used for indicating the server to determine a first processing resultcorresponding to the first exception identification information according to the first mapping relation, the processing request carries the first exception identification information, and the first exception identification information comprises a program identifier of the first program; wherein the first mapping relationship records a corresponding relationship between a plurality of pieces of exception identification information and a plurality of processing results, and each piece of exception identification information comprises a program identification. According to the abnormal running program in the vehicle-mounted system determined by the vehicle-mounted client, the processing result corresponding to the abnormality can be determined, so that manual repeated processing is avoided.

Owner:HUAWEI TECH CO LTD

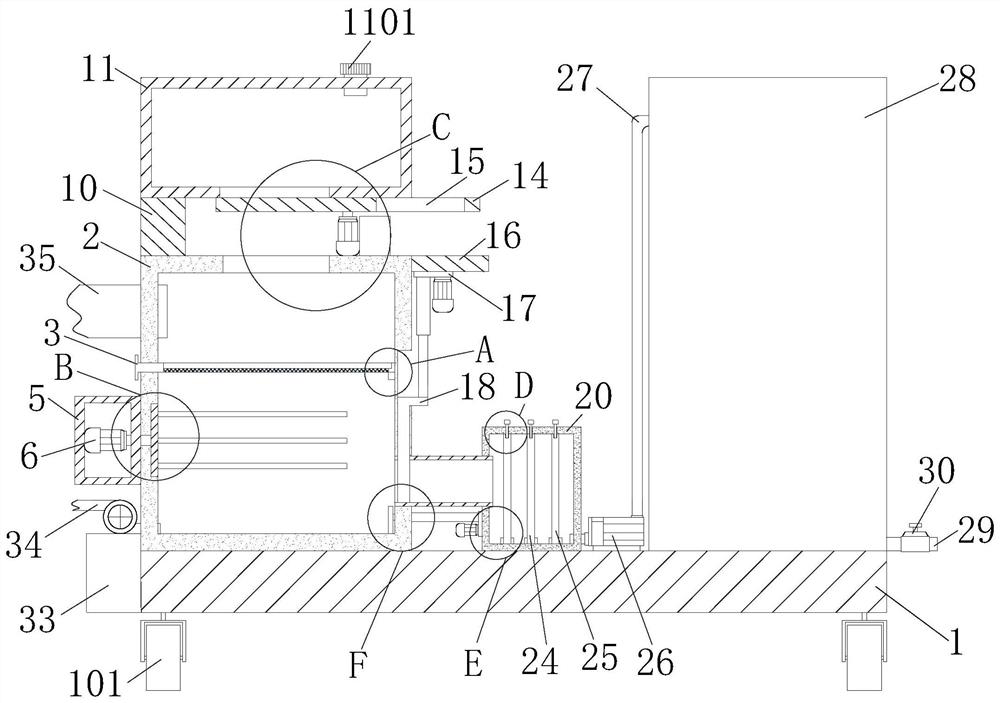

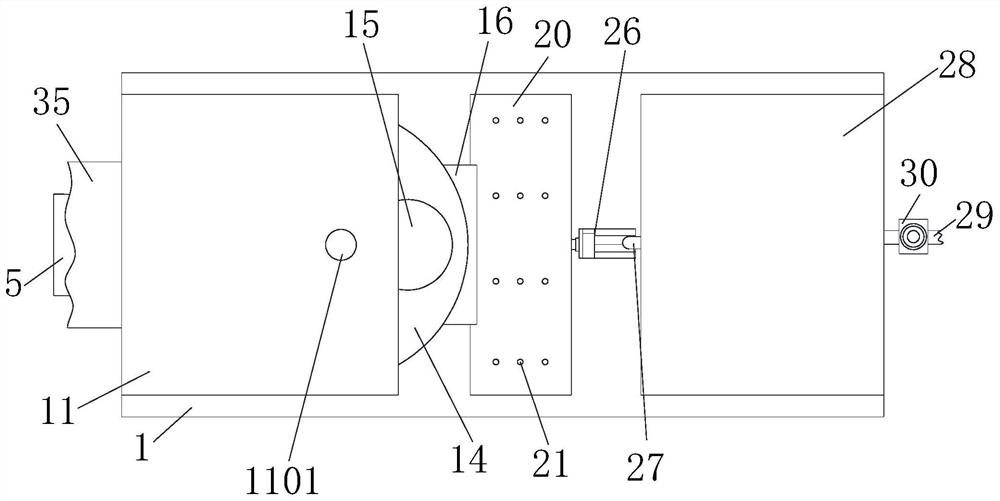

Industrial sewage treatment device and use method thereof

PendingCN113716752ALong cycleImprove work efficiencySpecific water treatment objectivesTreatment involving filtrationSewage treatmentSewage

The invention relates to the technical field of industrial sewage, and in particular, relates to an industrial sewage treatment device and a use method thereof. The invention aims to solve the technical problems that physical impurities exist in sewage, fine suspended solids and dissolved organic matters are not treated, and sludge exists. For solving the technical problems, the invention provides the industrial sewage treatment device and the use method thereof, wherein the industrial sewage treatment device is composed of a base, a settling tank, a filtering mechanism, a feeding mechanism and a desilting mechanism; first-time filtering is conducted through a filtering net plate, physical impurities in sewage are filtered out, and influences on sewage treatment in the later period are avoided; the device is provided with the feeding mechanism, so that the full combination reaction of alum and chemical wastewater is enhanced, the floc precipitation speed is increased, and the working efficiency of the device is enhanced; and the device is ingenious in design, manual treatment is not needed, sludge on the inner wall of the bottom of the settling tank is scraped through a push block, sludge in the device is conveniently removed, the service life of the device is prolonged, and the working efficiency is improved.

Owner:王开旭

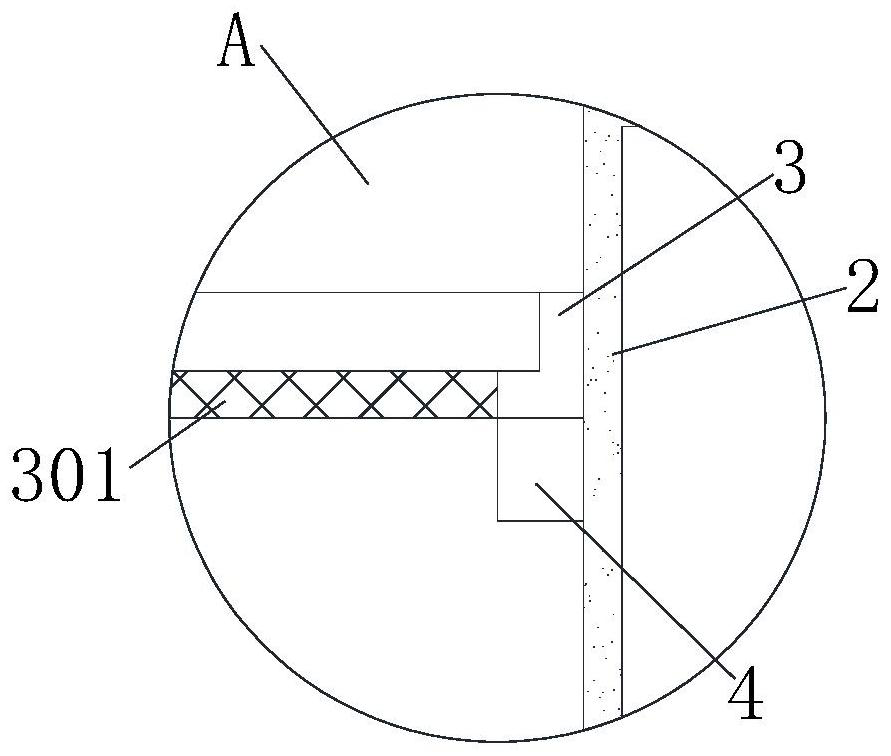

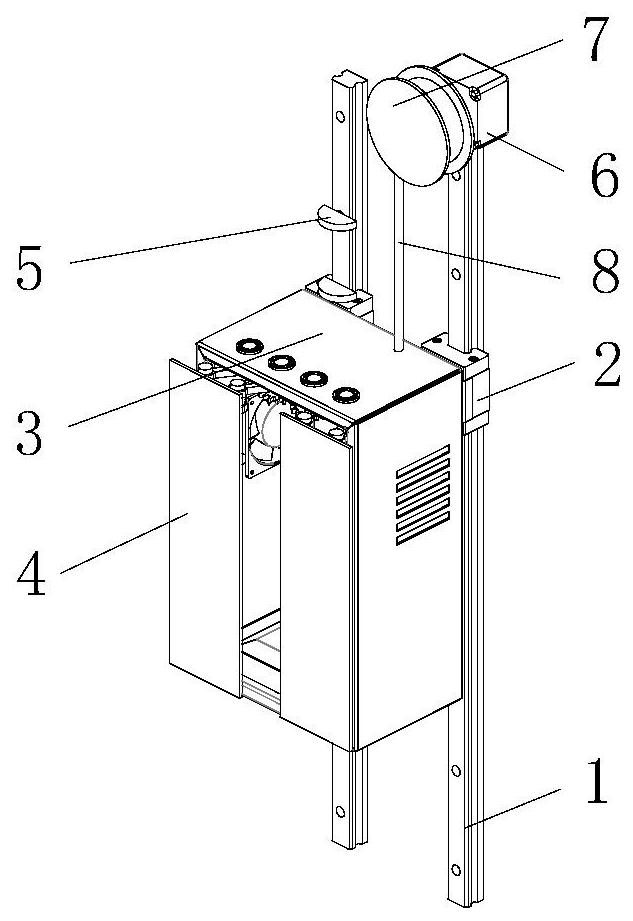

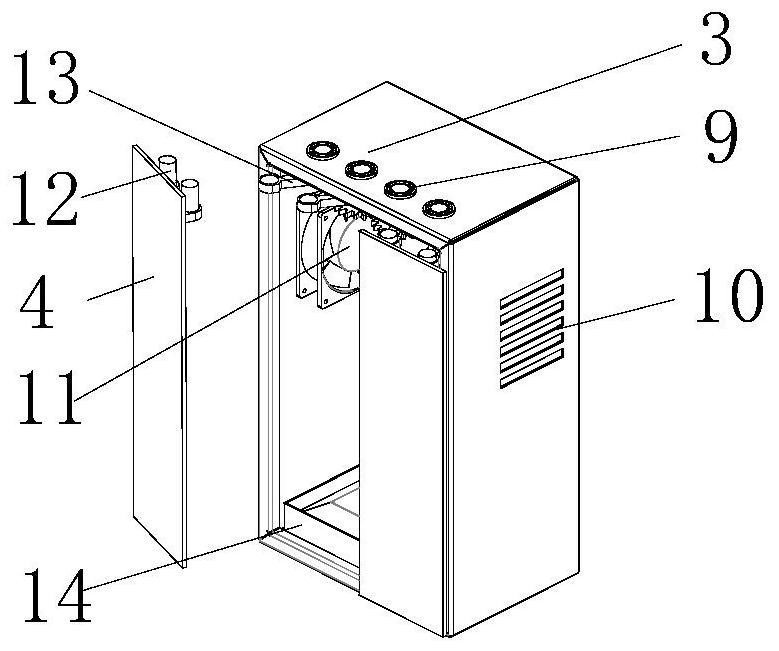

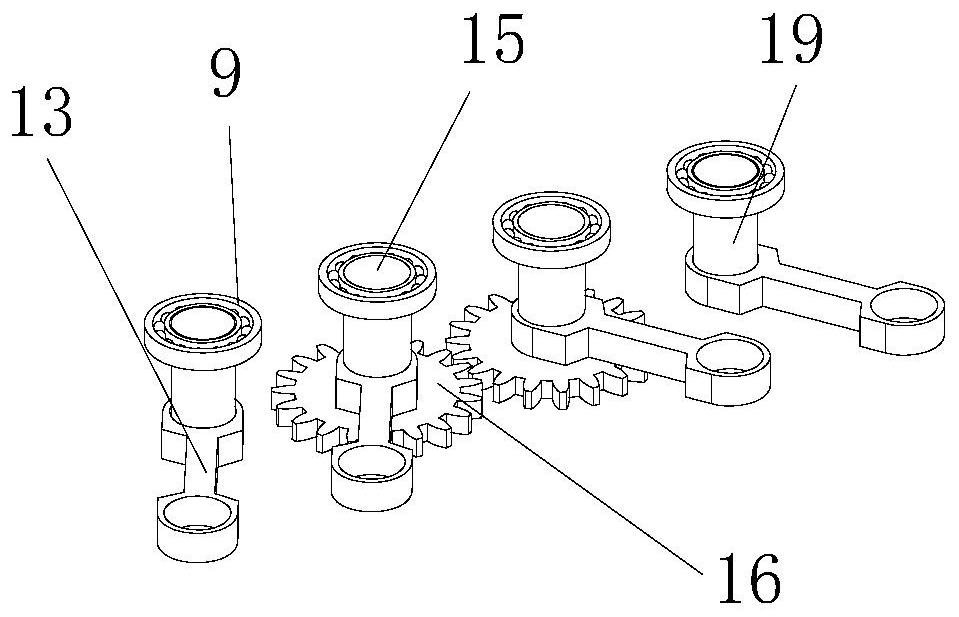

Electrical switch cabinet

InactiveCN112421429AEasy to collectSave operating spaceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsElectric machineEngineering

The invention discloses an electrical switch cabinet. The electrical switch cabinet comprises a distribution box body, guide rails, a sliding block and a motor; the distribution box body is slidably arranged on the guide rails through the sliding block; the guide rails are vertical guide rails which are vertically arranged; the motor is arranged at the tops of the guide rails; a lifting wire coilis arranged at the output end of the motor; a pull rope is arranged on the lifting wire coil; and the lower end of the pull rope is fixedly connected with the top of the distribution box body. The opening operation of the electrical switch cabinet is easy and convenient, and interference and collision with other objects are not prone to happening.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

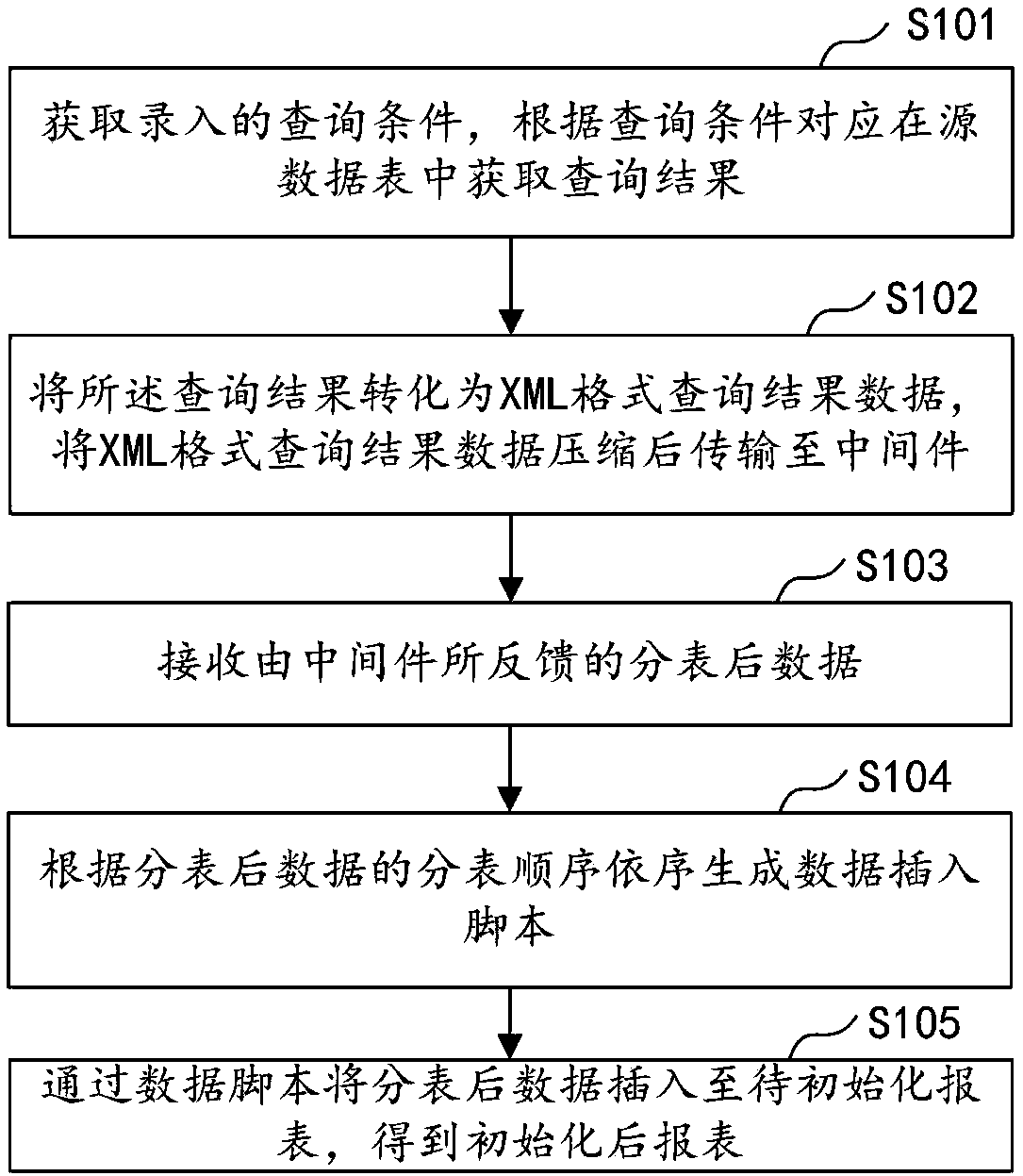

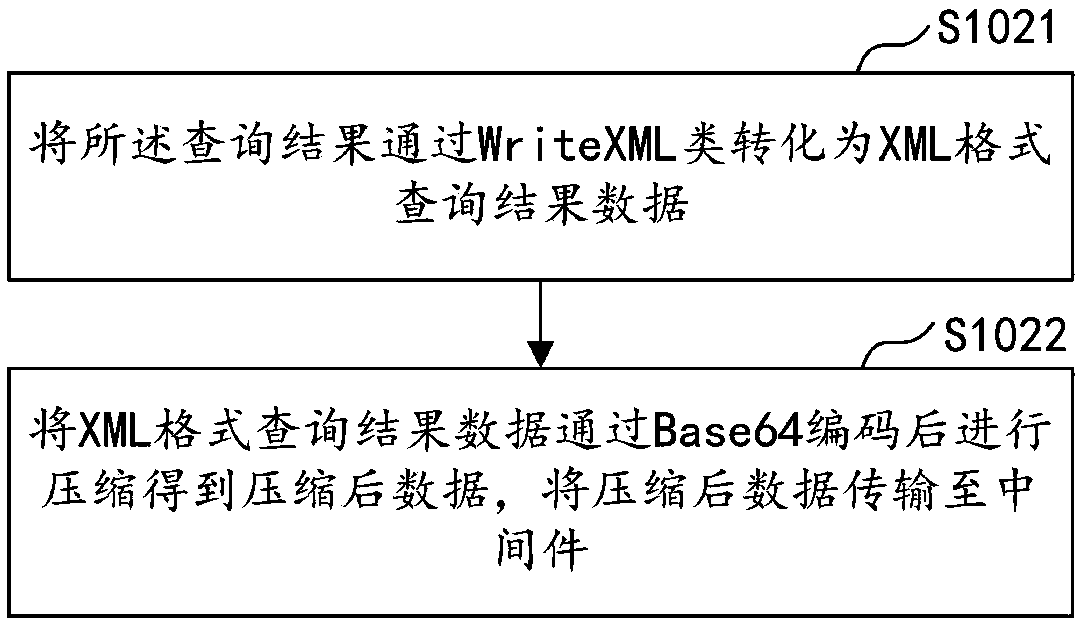

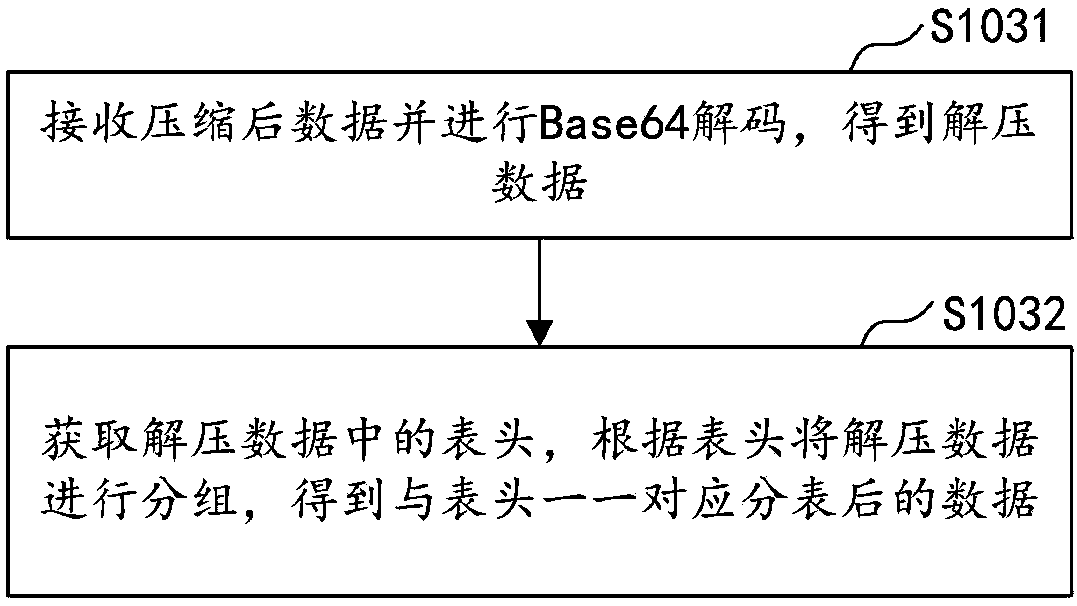

Report data initialization method and device, computer device and storage medium

ActiveCN108415894AImprove initialization efficiencyAvoid manual processingNatural language data processingSpecial data processing applicationsQuery statementMiddleware

The invention discloses a report data initialization method and device, a computer device and a storage medium. The method includes: obtaining entered query conditions, and obtaining query results inthe source data table according to the query conditions; converting the query results into XML format query result data, compressing the XML format query result data and transmitting the result data to middleware; receiving the data obtained after table partitioning, which is fed back by the middleware; generating data insertion scripts in sequence according to the order of the data after table partitioning; the data obtained after table partitioning is inserted into a report to be initialized through the data scripts, and the initialized report is obtained. The method automatically generatesa query statement according to the query conditions and the selected query database, automatically queries and returns the data results, and then automatically inserts the data results for initialization, thereby avoiding manual processing and improving report initialization efficiency.

Owner:PING AN TECH (SHENZHEN) CO LTD

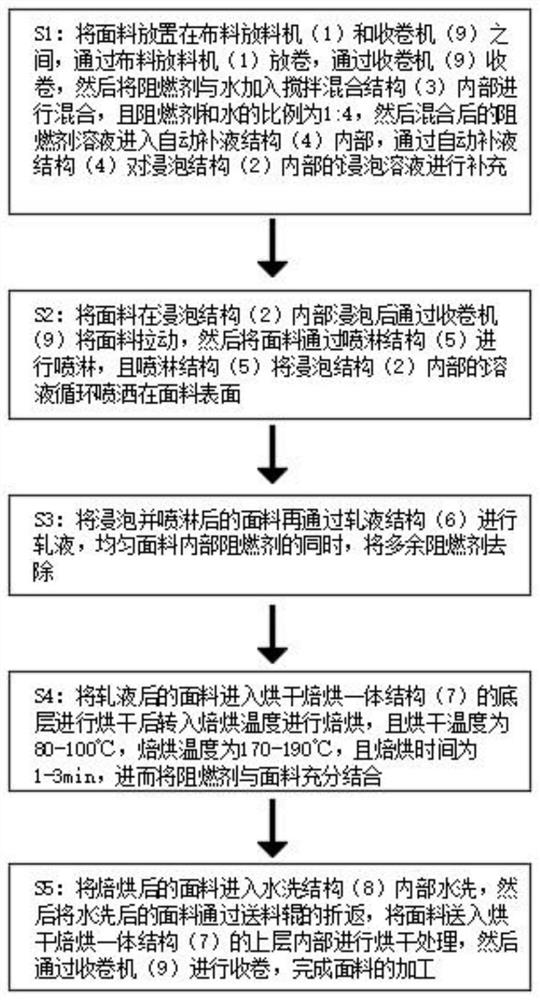

Novel antibacterial, wear-resistant and flame-retardant fabric and production and preparation method thereof

InactiveCN114411362AImprove flame retardant performanceIncrease productivityTextile storage in wounded formDrying gas arrangementsWinding machineProcess engineering

The invention discloses a novel antibacterial, wear-resistant and flame-retardant fabric and a production and preparation method thereof, and particularly relates to the technical field of fabric production.The production and preparation method comprises the following steps that S1, the fabric is placed between a cloth discharging machine and a winding machine, unwinding is conducted through the cloth discharging machine, winding is conducted through the winding machine, and the fabric is obtained; then a flame retardant and water are added into the stirring and mixing structure to be mixed, the ratio of the flame retardant to the water is 1: 4, and then the mixed flame retardant solution enters the automatic liquid supplementing structure; the cleaned fabric is soaked in the soaking structure with the mixed flame retardant, then flame-retardant components in the fabric are evenly pressed in a mangle expression mode, then the fabric is produced through drying, baking, water washing and drying, then the flame-retardant components are added into the antibacterial and wear-resistant fabric, and therefore the flame-retardant effect of the fabric is improved, and the flame-retardant effect of the fabric is improved. Meanwhile, the preparation equipment is subjected to automatic process operation, so that a user is prevented from manually treating the fabric, and the production efficiency of the fabric is improved.

Owner:连云港丰华纺织科技有限公司

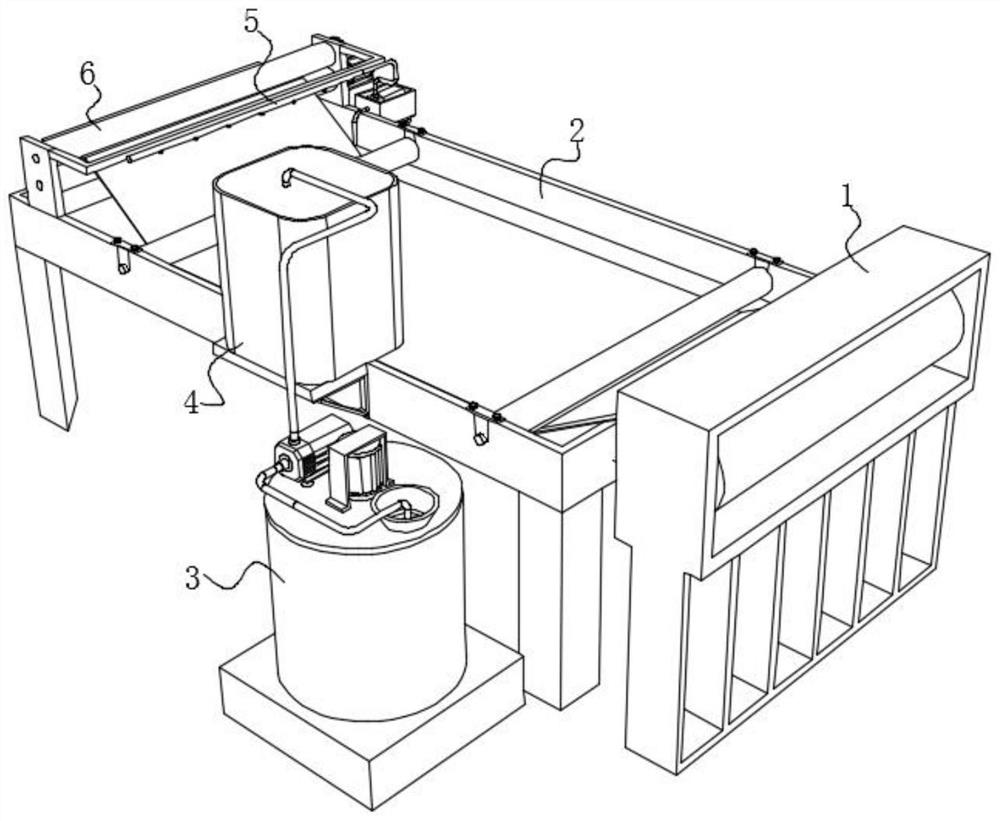

Surface treatment of rubber using low pressure plasma

ActiveUS9381543B2Shorten the timeReduce usageLiquid surface applicatorsSynthetic resin layered productsRubber materialSurface layer

A method of treating a surface of an object comprising a rubber material and in particular a bladder for use in a process for making a vehicle tire. The method comprises subjecting the surface to a gas at a low pressure at which the gas is susceptible of forming plasma, and causing the gas to form plasma. In order to obtain repellent properties of the surface of the rubber material fluorine gas such as tetrafluormethane or hexafluorethane is used. Preferably the treatment is performed until there is obtained a surface layer of the rubber material with properties modified by the treatment having an expected lifetime corresponding to the expected lifetime of the object.

Owner:MUNCH CHEM INT

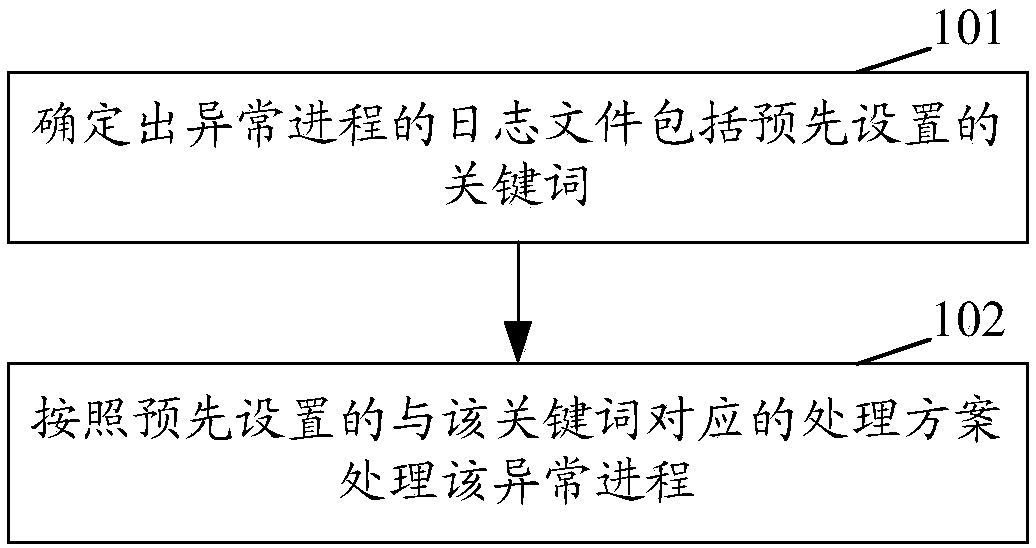

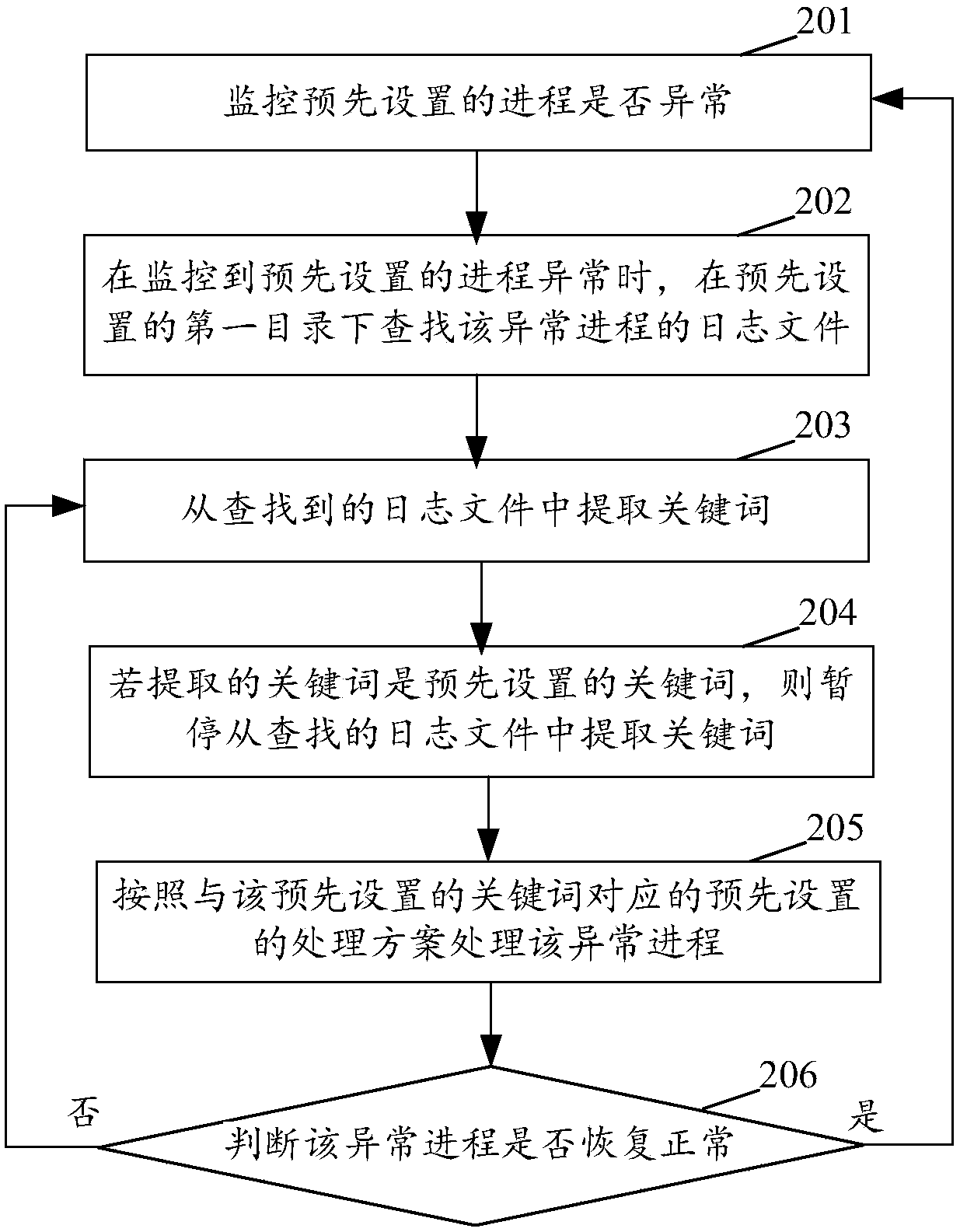

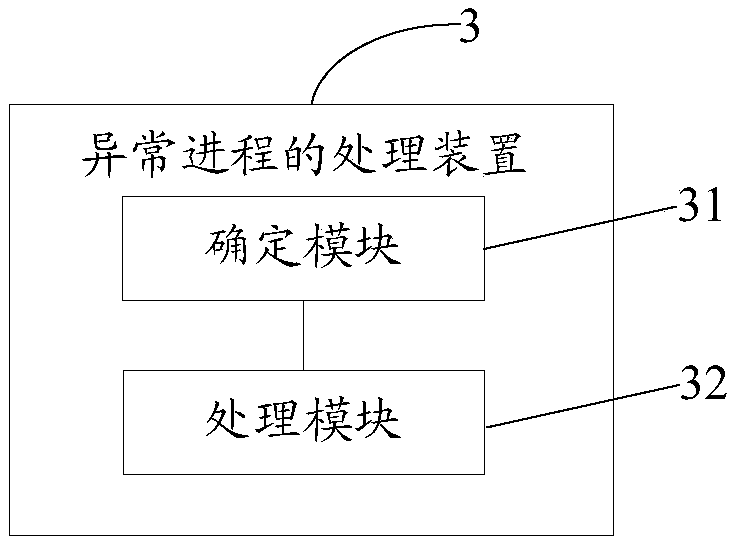

Abnormal process treatment method and device

InactiveCN107678878AImprove processing efficiencyAvoid manual processingNon-redundant fault processingRedundant operation error correctionComputer scienceAutomatic processing

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

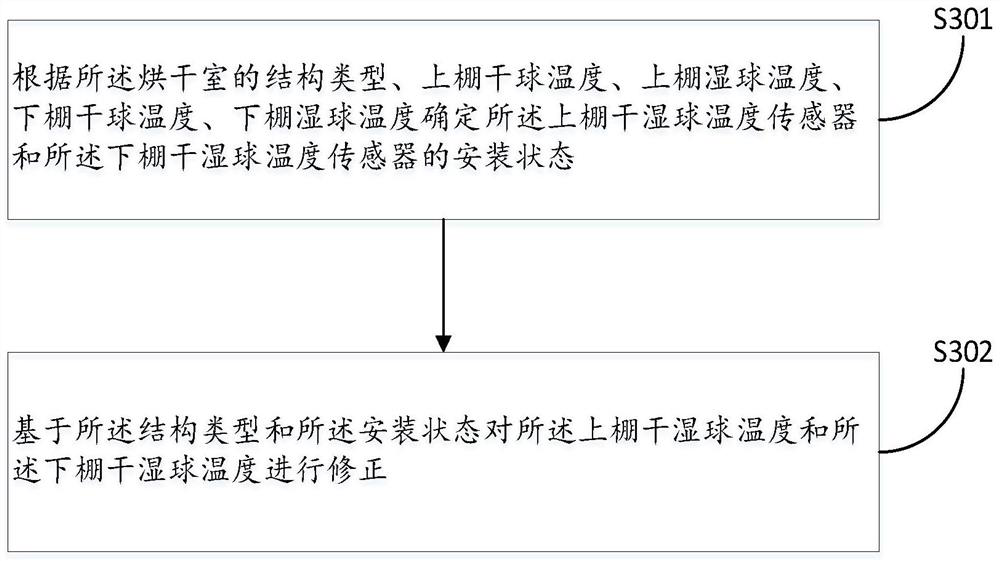

Tobacco dryer and dry-wet bulb temperature sensor control method

ActiveCN112602958AAvoid manual processingAvoid exceptionTobacco preparationFinal product manufactureThermodynamicsEngineering

The invention discloses a tobacco dryer and a dry-wet bulb temperature sensor control method. The tobacco dryer comprises: an indoor unit comprising an indoor heat exchanger working as a condenser and used for providing heat for a drying chamber; an outdoor unit comprising a compressor and an outdoor heat exchanger working as an evaporator; a curing barn located in the drying chamber and used for storing tobaccos needing to be baked; an upper shed dry-bulb temperature sensor; an upper shed wet-bulb temperature sensor; a lower shed dry-bulb temperature sensor; a lower shed wet-bulb temperature sensor; and a controller configured to obtain the structure type of the drying chamber, wherein the structure type comprises an airflow descending type and an airflow ascending type. The installation states of the upper shed dry-wet bulb temperature sensors and the lower shed dry-wet bulb temperature sensors are determined based on the structure type, the upper shed dry-wet bulb temperatures and the lower shed dry-wet bulb temperatures, the upper shed dry-wet bulb temperatures and the lower shed dry-wet bulb temperatures are corrected based on the structure type and the installation states, and the curing room temperature is adjusted in time to avoid abnormity in the curing process.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Automatic potato chip frying device for food processing

InactiveCN112021347AImprove processing throughputGuarantee personal safetyOil/fat bakingMetal working apparatusChipped potatoesVehicle frame

The invention relates to a frying device, in particular to an automatic potato chip frying device for food processing. The invention provides the automatic potato chip frying device for food processing, which is easy to operate and high in safety. The automatic potato chip frying device for food processing provided by the invention comprises a vehicle frame, a feeding device, a cutting device, a pushing handle and a frying pan, wherein a fixing table is arranged in the middle of the top of the vehicle frame; the feeding device is arranged at the top of the fixing table; the cutting device is arranged on one side of the feeding device; the pushing handle is arranged on one side of the vehicle frame; and the frying pan is arranged on one side, far away from the pushing handle, of the vehicleframe. Compared with the prior art, the automatic potato chip frying device has the advantages that potatoes of various sizes can be automatically sliced and processed into potato chips, manual processing is avoided, and the slicing efficiency is improved.

Owner:钟巧文

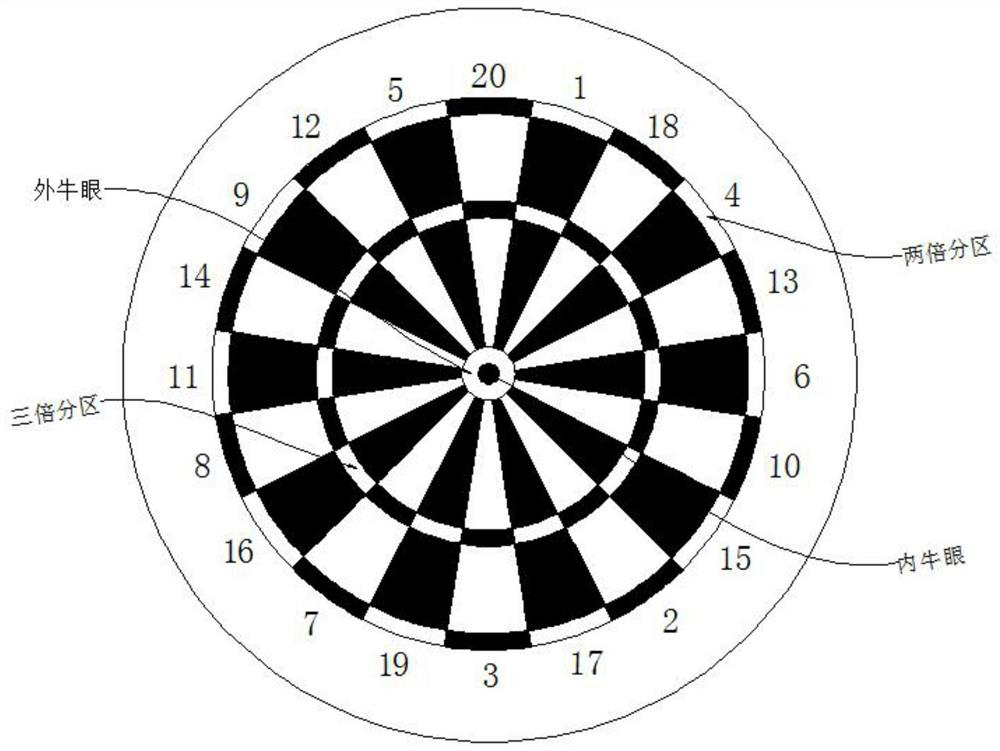

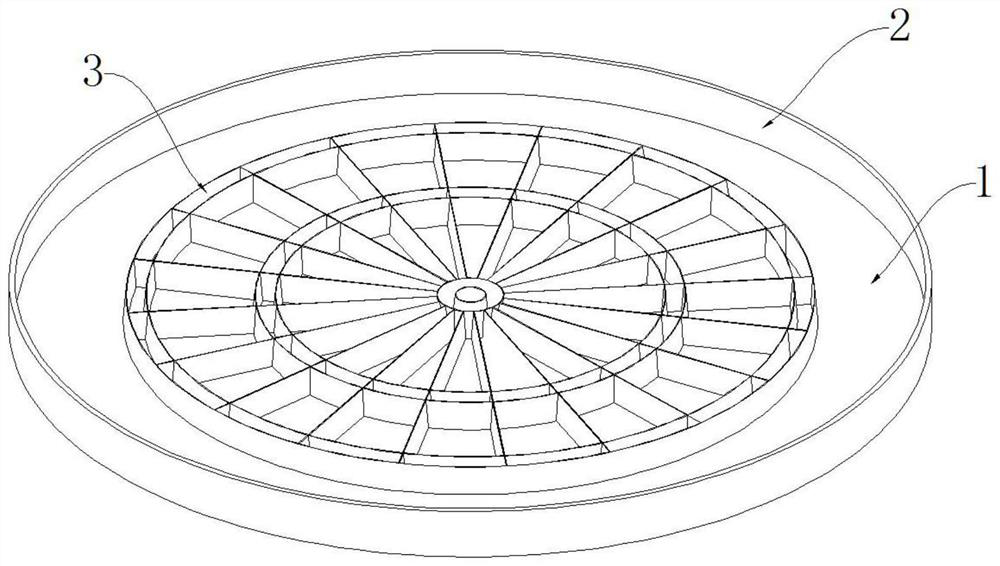

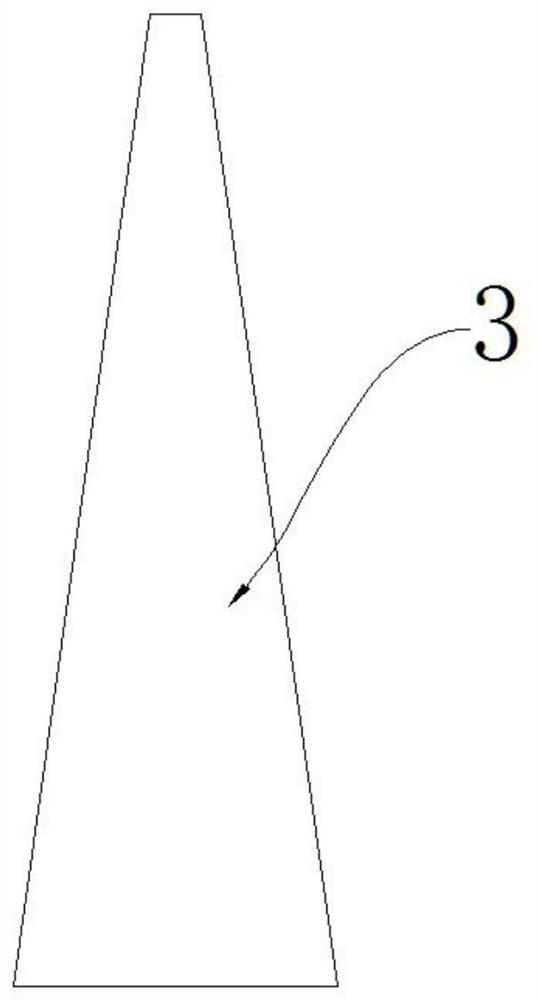

Magnetic induction coil wiring structure and magnetic induction type electronic target

InactiveCN111721162AEffective scoring spaceDoes not affect wiringDartboardsTarget surfaceCondensed matter physics

The invention discloses a magnetic induction coil wiring structure and a magnetic induction type electronic target. According to the electronic target, a sheet-shaped protrusion extending into a target body is arranged at the position, corresponding to each partition line, of a bottom plate, and the sheet-shaped protrusions corresponding to the radial partition lines and sheet-shaped protrusions corresponding to the annular partition lines penetrate through each other to form net-shaped protrusions used for containing a magnetic induction coil set. According to the electronic target, startingfrom the bottom plate in a breakthrough mode, the net-shaped protrusions extending into the target body are arranged, the wiring mode of the target surface structure is not affected, wiring machiningis facilitated, and meanwhile the occupied effective scoring space of the target surface is small.

Owner:王照

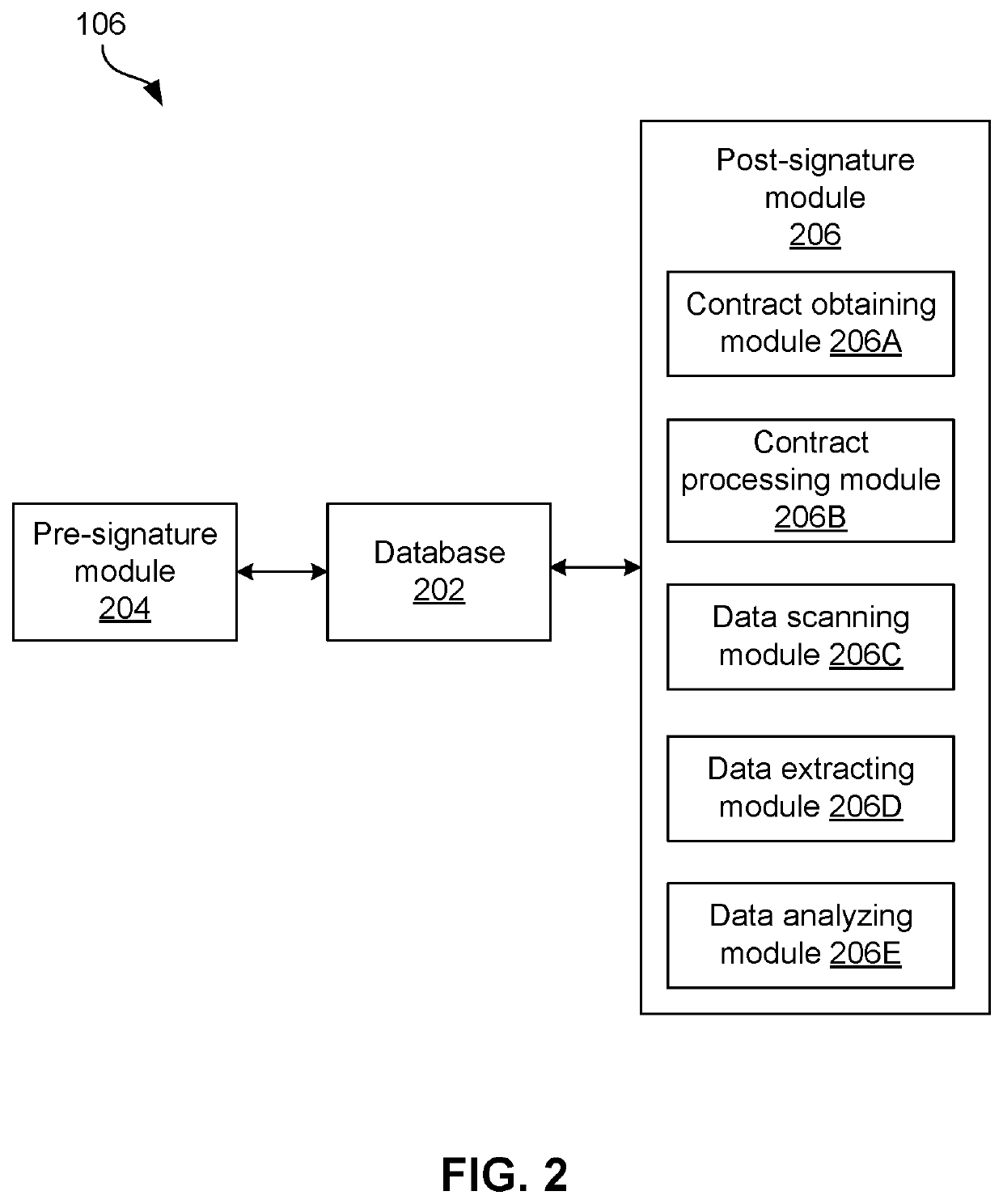

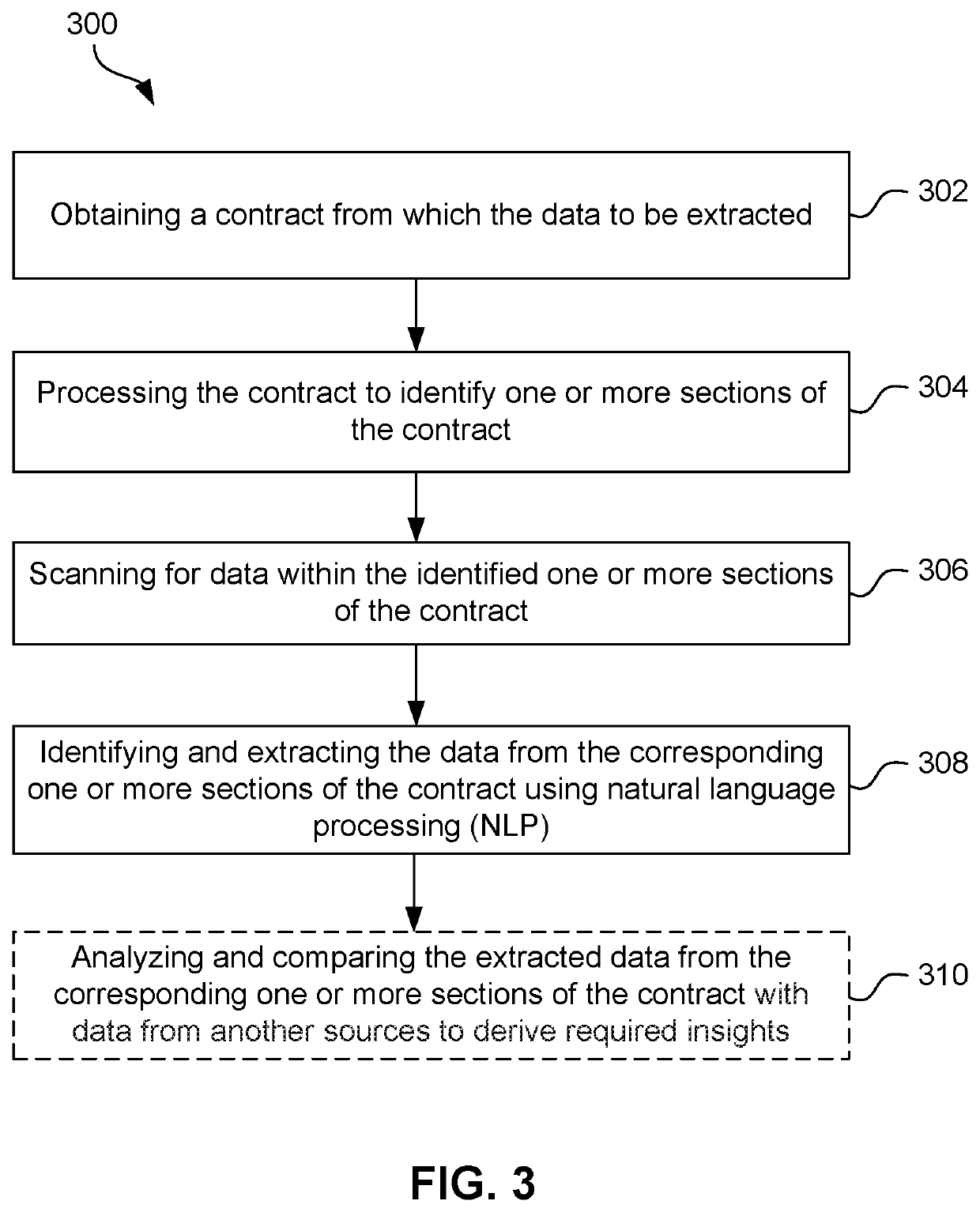

System and method for extracting data from contracts using ai based natural language processing (NLP)

PendingUS20220092711A1Easy to useQuick implementationData processing applicationsEngineeringData mining

Disclosed is a method for extracting data from contracts using a contract data extraction system. The method includes following steps of: obtaining a contract from which the data to be extracted; processing the contract to identify one or more sections of the contract; scanning for data within the identified one or more sections of the contract; and identifying and extracting the data from the corresponding one or more sections of the contract using natural language processing (NLP). The one or more sections include at least one of clauses, obligations, signature and tabular data. The one or more sections are identified using a predefined library. The identified one or more sections are demarcated by matching with the predefined library. The identified one or more sections are tagged across existing and new contract repositories using the Artificial Intelligence (AI) technique.

Owner:SIMPLICONTRACT TECH PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com