Cold recycler with cross sliding type working roll

A surface cold recycling machine, traverse technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of high cost, the road edge cannot be completely cleaned, the structure of the driver's cab is complicated, and the structure is compact, and the road edge cannot be solved. Thorough cleaning to avoid the effect of artificial assistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

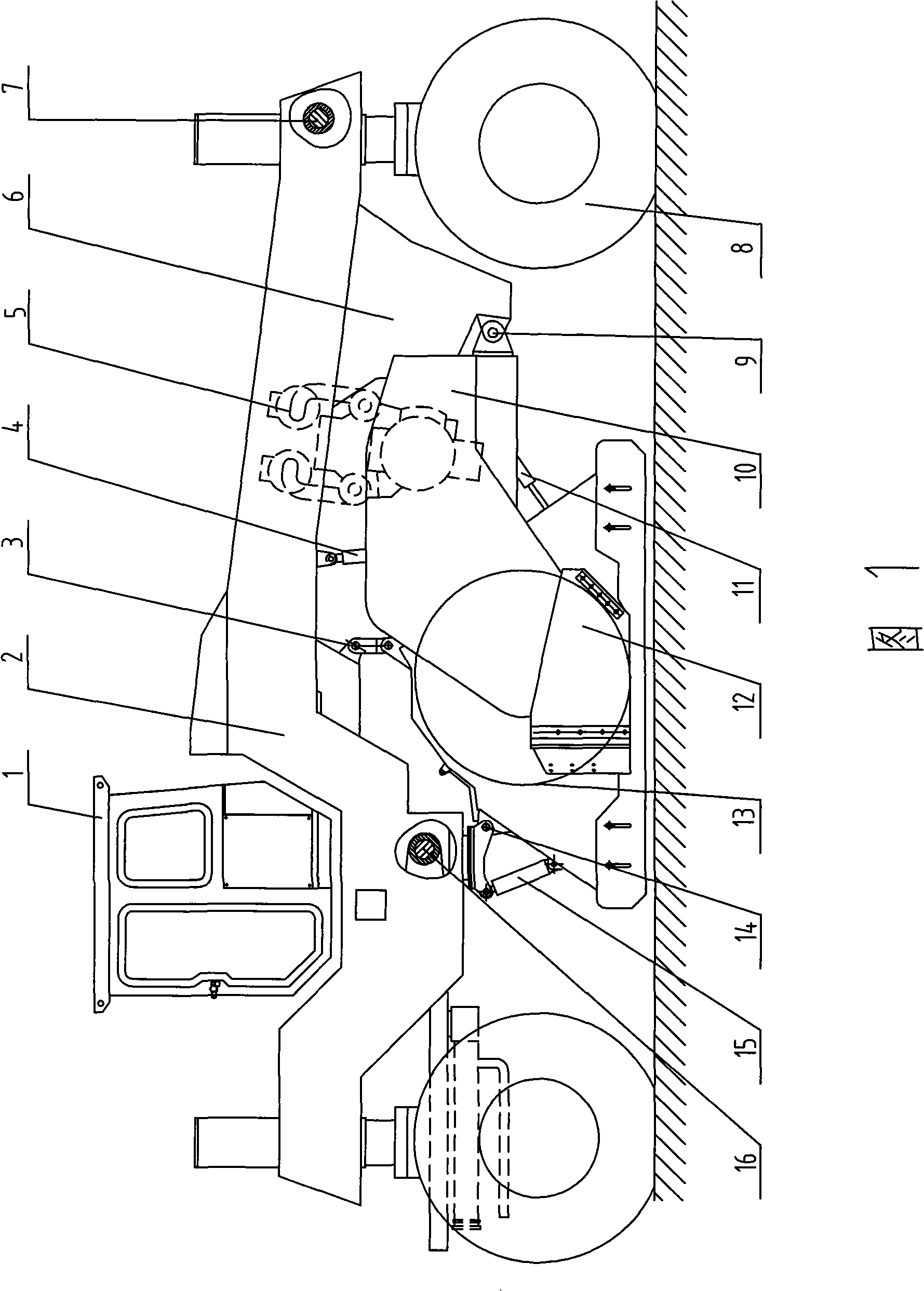

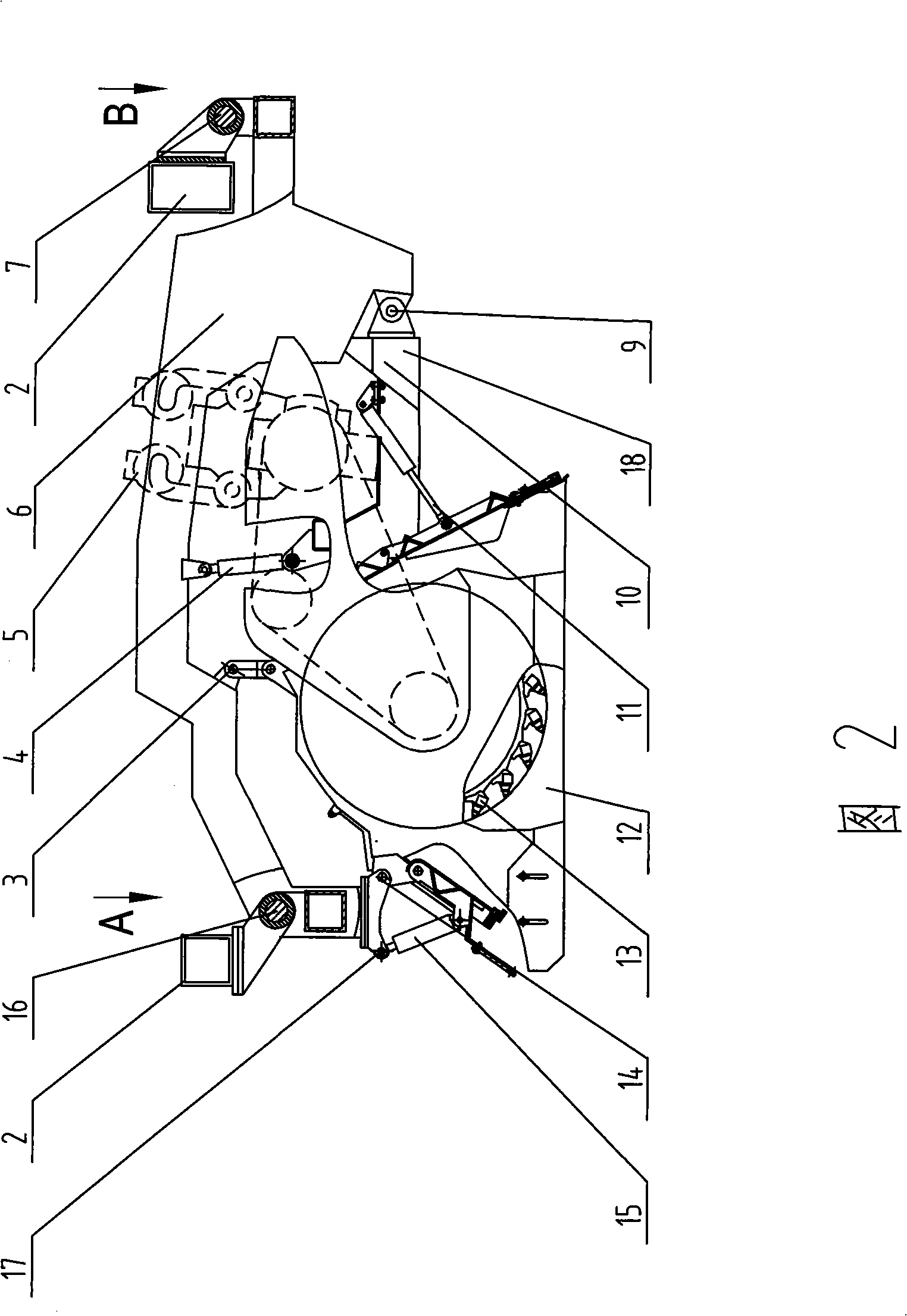

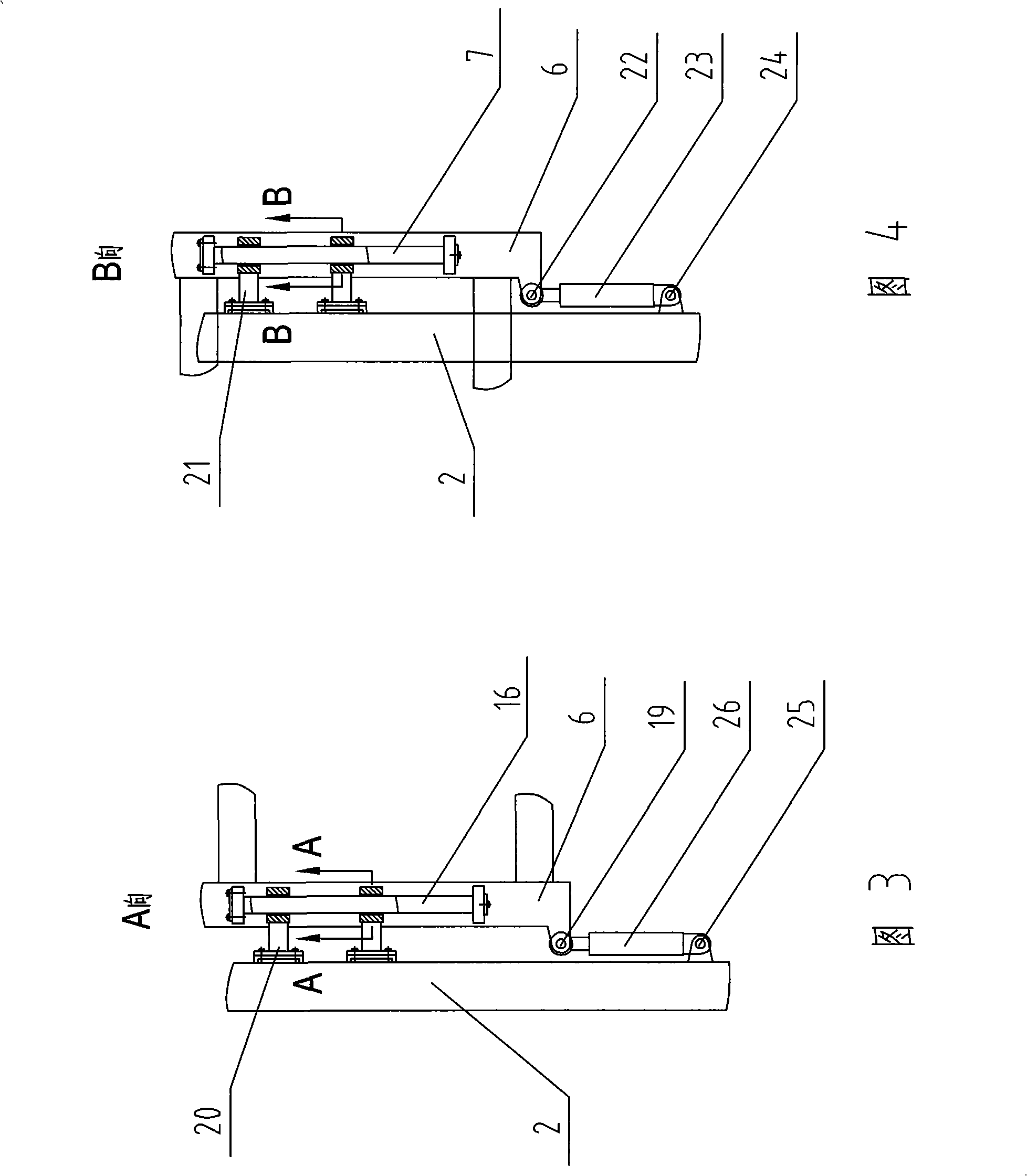

[0022] according to Figure 1-8 The specific structure and working process of the present invention are described in detail with the embodiment. This transversely moving work roll road surface cold recycling machine includes a four-wheel drive traveling mechanism 8 commonly used in the prior art and a car body 2 supported thereon, a driver's cab 1 assembled on the car body 2, and a vehicle body assembled on the car body 2 by The work roll adjustment control mechanism composed of the adjustment frame 10, the outer cover 12 with the built-in work roll 13 and its driving device 5, and the lateral sliding mechanism composed of the front and rear sliding parts are matched by the conventional control elements corresponding to the above components. operation console, etc.

[0023] Such as figure 1 As shown, the driving device 5 of the present embodiment still adopts a traditional engine transmission, except as the power to drive the work roll 13 to rotate, it is also the power of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com