Automatic potato chip frying device for food processing

A technology for food processing and potato chips, used in metal processing, oil/fat baking, etc., can solve the problems of personal threats to staff, cumbersome production process, inconvenient operation, etc., to improve processing production, ensure processing quality, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

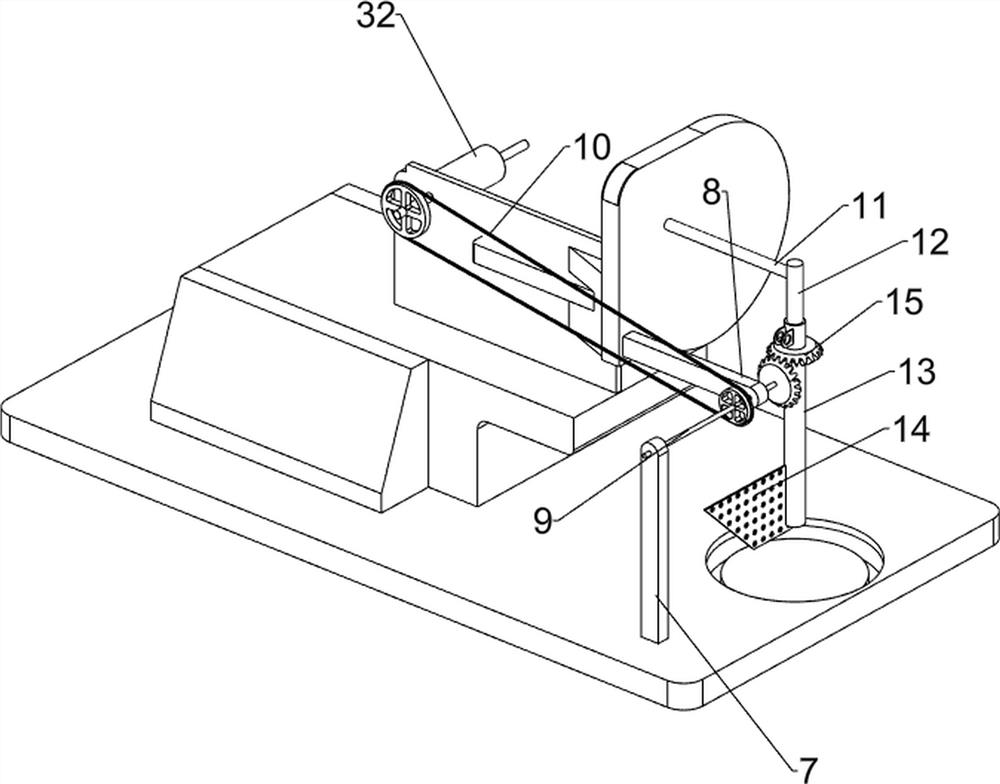

[0023] like Figure 1-3 As shown, an automatic potato chip frying device for food processing includes a vehicle frame 1, a fixed platform 2, a feeding device 3, a cutting device 4, a pusher 5 and a fryer 6, and a fixed platform is arranged in the middle of the top of the vehicle frame 1 2. A feeding device 3 is installed on the top of the fixed platform 2, a cutting device 4 is installed on one side of the feeding device 3, a push handle 5 is installed on one side of the frame 1, and a fryer 6 is placed on the front side of the frame 1.

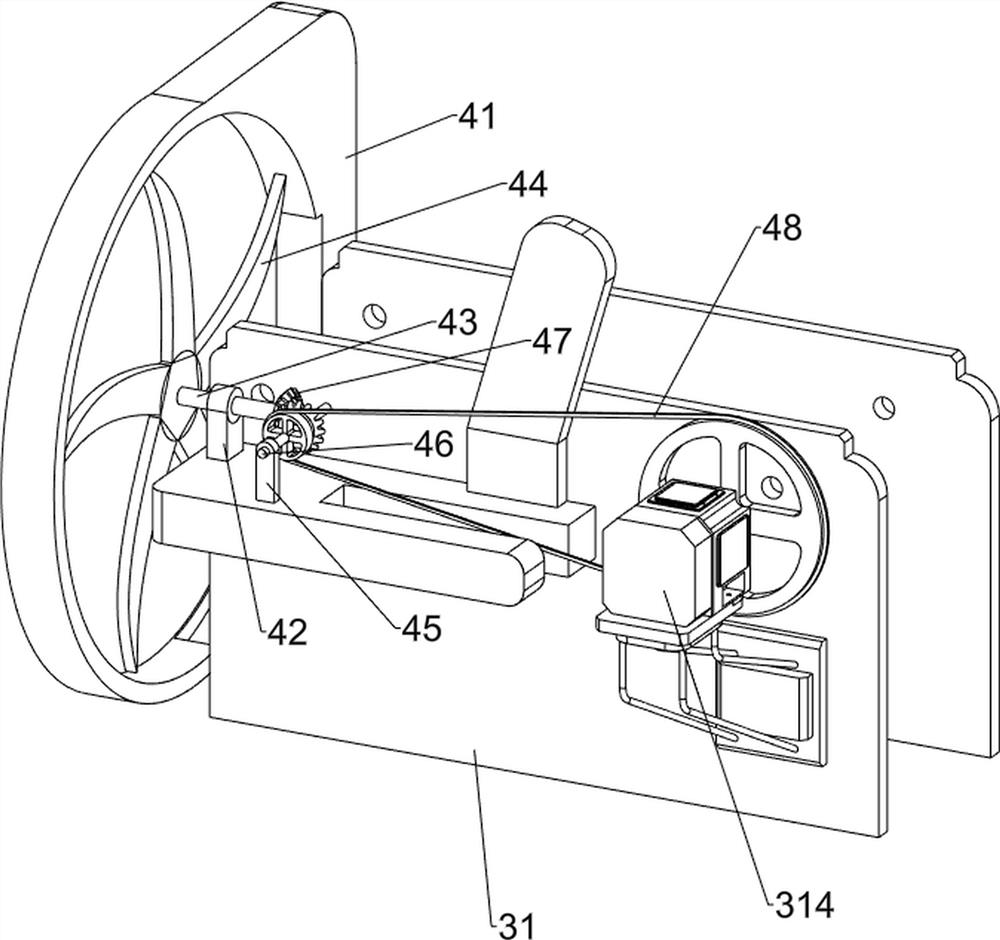

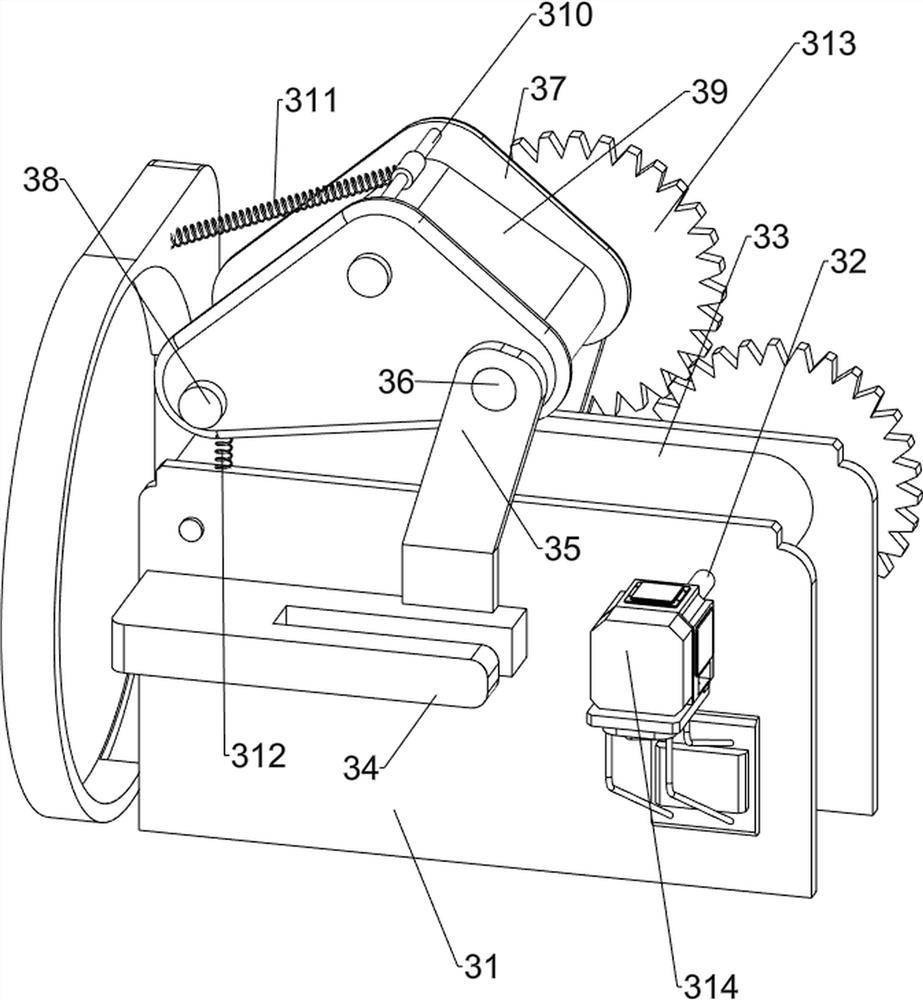

[0024] The feeding device 3 includes a mounting plate 31, a first cylinder 32, a first conveyor belt 33, a fixed plate 34, a mounting frame 35, a first rotating shaft 36, a triangular plate 37, a second cylinder 38, a second conveyor belt 39, a fixed shaft 310, The first elastic member 311, the second elastic member 312, the circular gear 313 and the servo motor 314, the mounting plate 31 is symmetrically arranged on the top of the fixed tabl...

Embodiment 2

[0028] like Figure 4-5 As shown, a potato chip automatic frying device for food processing, on the basis of embodiment 1, also includes a first fixed frame 7, a second fixed frame 8, a third rotating shaft 9, a second belt transmission mechanism 10 , fixed rod 11, slide rod 12, sliding sleeve shaft 13, flip plate 14 and second bevel gear 15, the front side of the top of the vehicle frame 1 is provided with the first fixed frame 7, and the bottom of the side wall of the baffle plate 41 is provided with the second fixed frame. The frame 8, the first fixed frame 7 and the second fixed frame 8 are rotatably provided with a third rotating shaft 9, and the left end of the first drum 32 on the rear side is connected to the third rotating shaft 9 through a second belt transmission mechanism 10. A fixed rod 11 is arranged above the side wall of the baffle plate 41, the other end of the fixed rod 11 is provided with a slide rod 12, the bottom of the slide rod 12 is slidably provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com