Petrochemical engineering wharf handling process safety early-warning system based on LabVIEW

A petrochemical and early warning system technology, applied in pipeline systems, instruments, data processing applications, etc., can solve problems such as scattered management resources, complicated operations, and weak police force, so as to improve data calculation speed and avoid redundant manual labor The effect of processing work, convenient maintenance and function expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

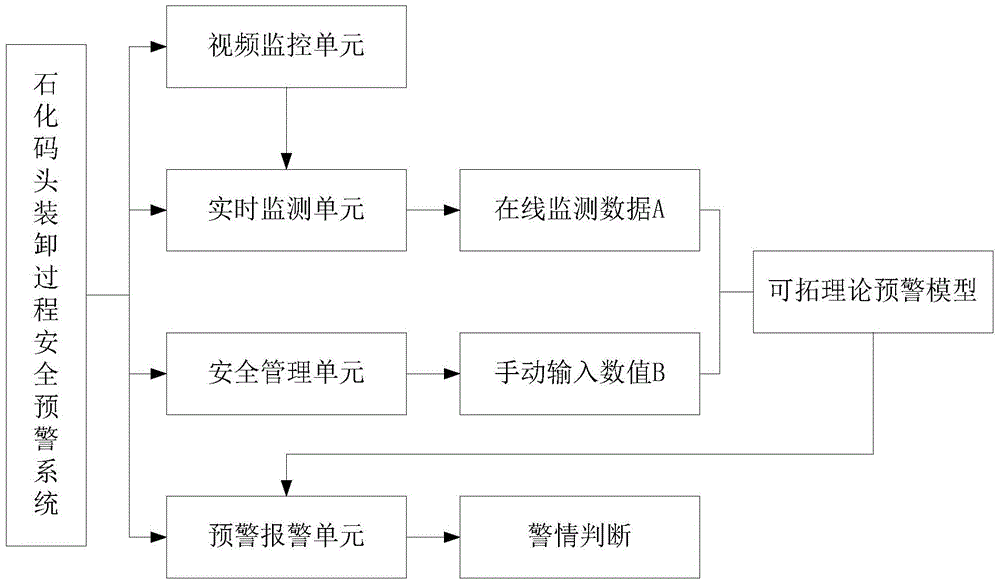

Embodiment 1

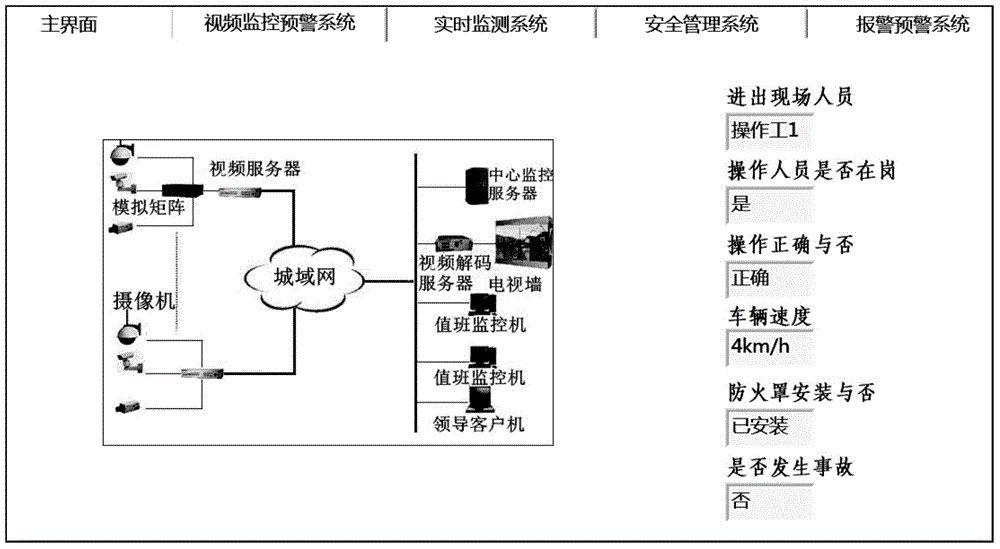

[0027] Video surveillance unit for video surveillance of the entire site ( image 3 ), record personnel entering and leaving the site, whether they are on duty, and whether the operation is correct or not. Install gas sensors near the loading and unloading equipment in the petrochemical loading and unloading area to monitor the leakage of toxic, harmful, flammable and explosive gases. The camera focuses on loading and unloading equipment and the loading and unloading process; for the monitoring of the oil pipeline, see the real-time monitoring unit of the present invention; for the monitoring of the transport vehicle, including the speed of the vehicle, the installation of the fire cover, the transportation route, the leakage of chemicals and the whole process of traffic accidents.

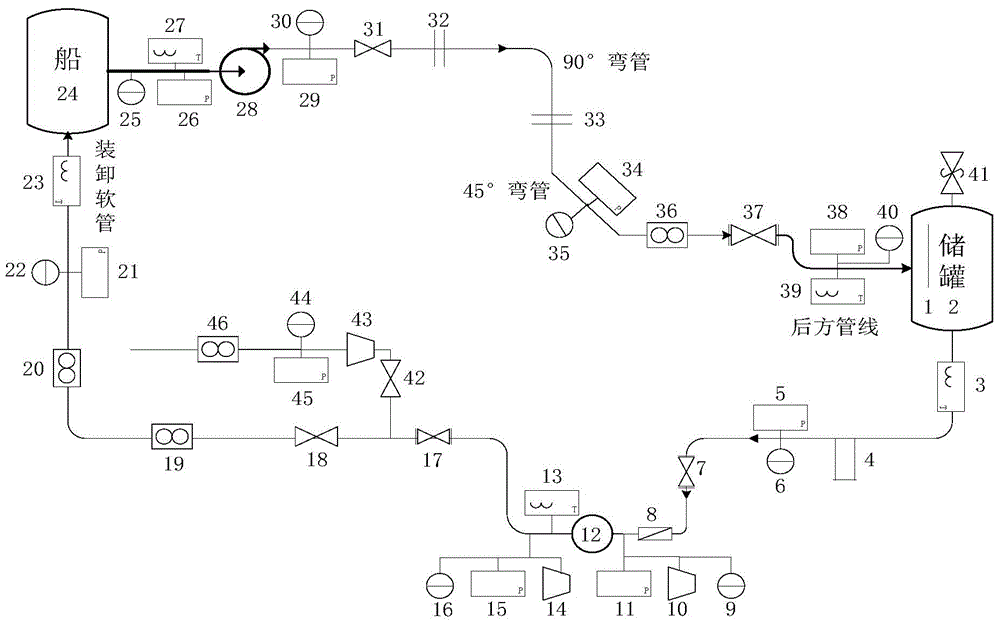

[0028] The real-time monitoring unit specifically refers to the monitoring of parameter changes and its corresponding test system during liquid loading and unloading operations. The system is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com