Novel antibacterial, wear-resistant and flame-retardant fabric and production and preparation method thereof

A kind of fabric and a new technology, applied in the field of fabric processing, can solve the problems of lack of flame retardant effect of fabric, complex internal structure, and many electrical appliances used, so as to achieve the effect of increasing cleaning effect, increasing use effect and speeding up drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

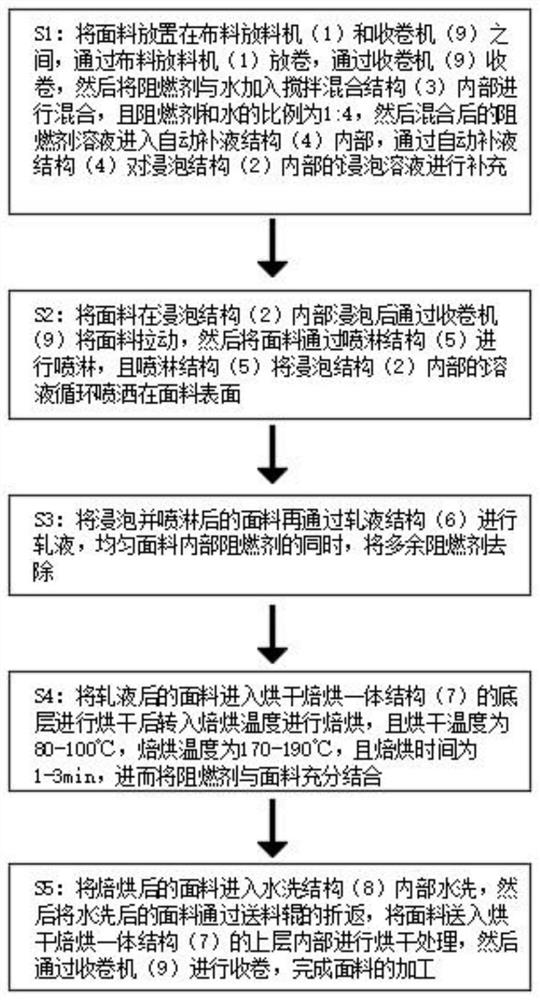

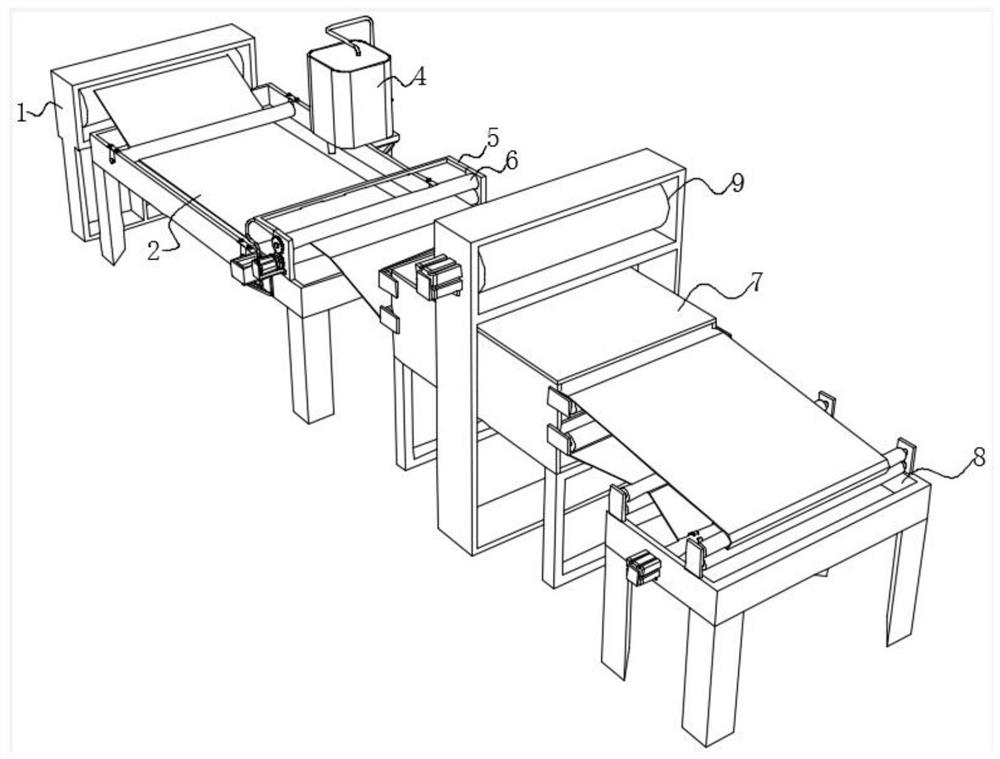

[0042] An antibacterial, wear-resistant and flame-retardant novel fabric and a production and preparation method thereof, specifically comprising the following steps:

[0043] S1: Place the fabric between the fabric unwinding machine 1 and the winder 9, unwind through the fabric unwinder 1, wind up through the winder 9, and then add the flame retardant and water into the stirring and mixing structure 3 to carry out Mixing, and the ratio of the flame retardant to water is 1:4, and then the mixed flame retardant solution enters the interior of the automatic liquid replenishment structure 4, and replenishes the soaking solution inside the soaking structure 2 through the automatic liquid replenishment structure 4;

[0044] S2: After the fabric is soaked in the soaking structure 2, the fabric is pulled by the winding machine 9, and then the fabric is sprayed through the spray structure 5, and the spray structure 5 circulates and sprays the solution inside the soaking structure 2 on ...

Embodiment approach

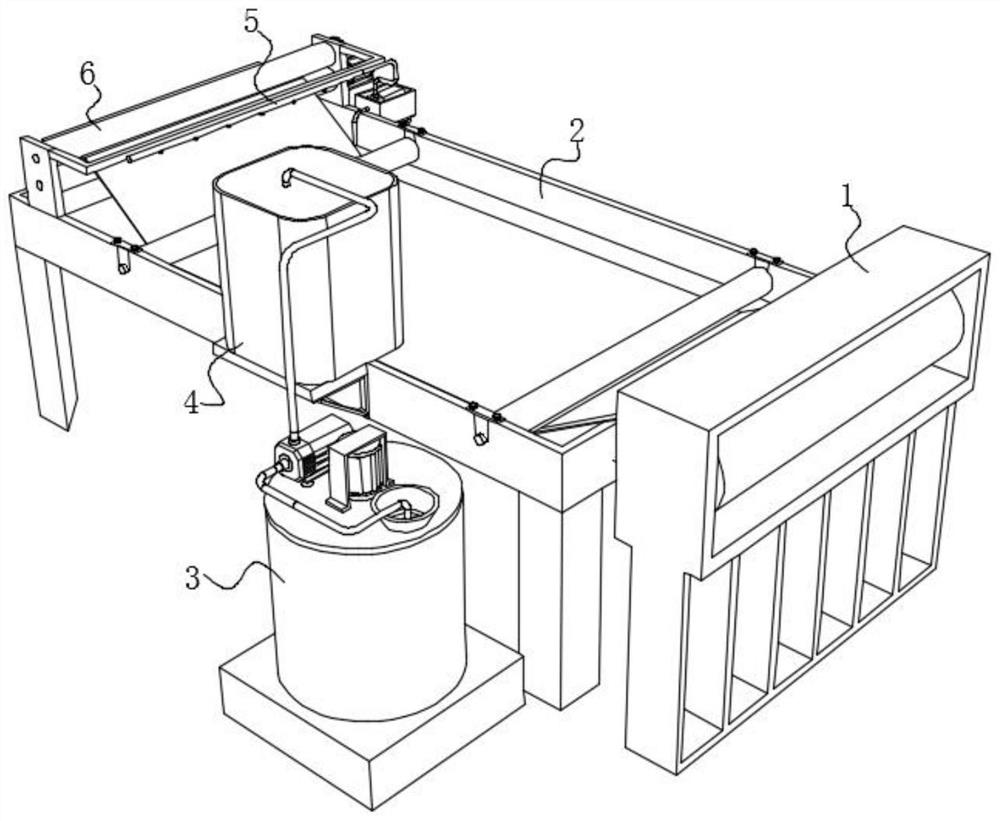

[0052] The implementation method is as follows: pour the flame retardant and water into the mixing tank 31 according to the proportion, then drive the stirring rod 34 through the stirring motor 33, and then mix the solution through the stirring paddle 35, and after the mixing is completed, the liquid pumping pump 43 is turned on and used, and the liquid suction pump 43 extracts the mixed solution inside the mixing tank 31 through the liquid suction pipe 44, and the liquid suction pipe 44 is a hose structure, and then it is convenient to take out the liquid suction pipe 44 from the inside of the mixing tank 31, and when mixing When the bucket 31 is used for mixing, the liquid suction pipe 44 is taken out, and when the solution is drawn, the liquid suction pipe 44 is put into the inside of the mixing bucket 31 from the liquid inlet 36, and the extracted solution enters the inside of the liquid storage tank 41 through the connecting pipe 42, and The bottom end surface of the air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com