Method for rapidly smelting zirconium-based amorphous alloy master alloy

A zirconium-based amorphous alloy and master alloy technology, applied in the field of amorphous alloys, can solve the problems of increasing process links, cumbersome preparation methods, affecting the forming of amorphous alloys, etc., so as to increase the service cycle, simplify the smelting process, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

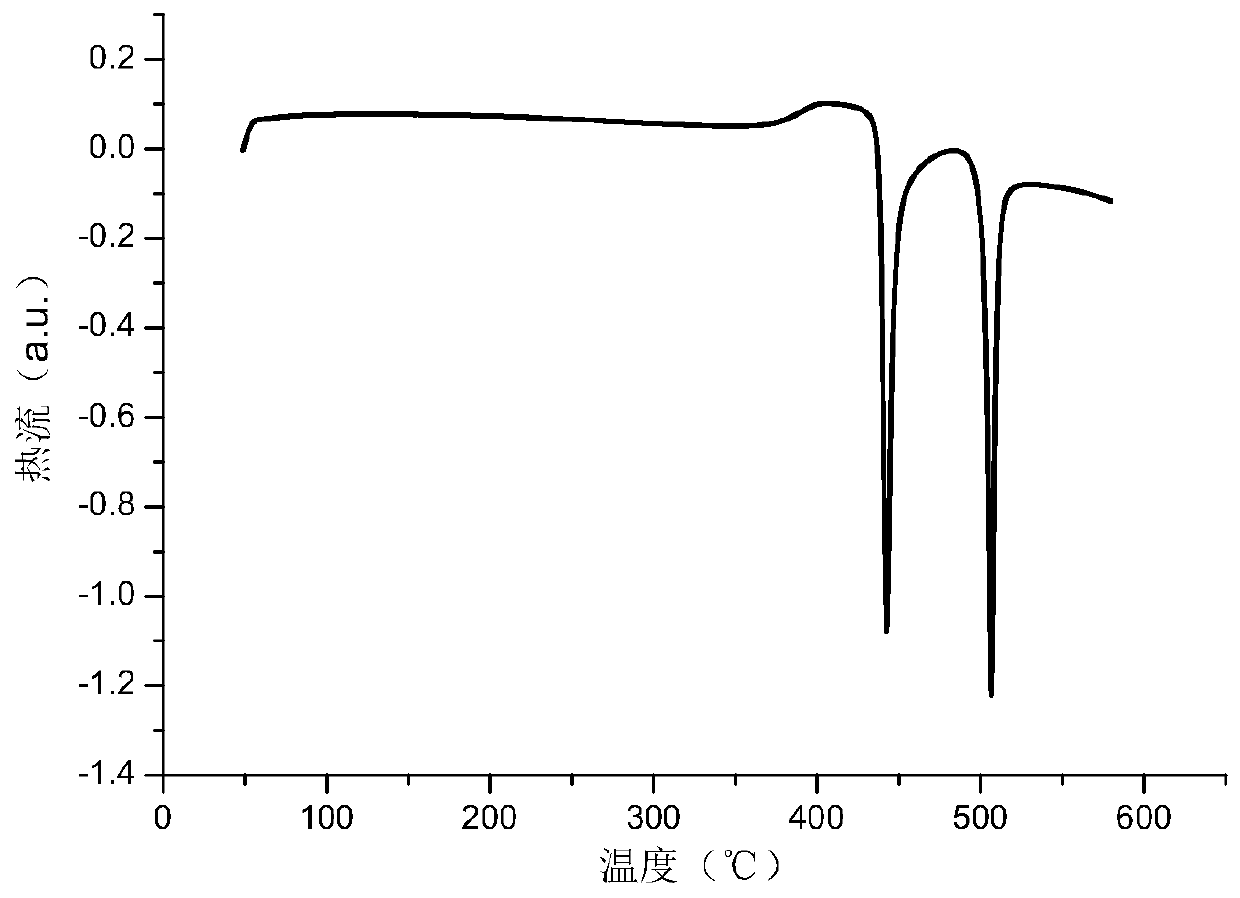

Image

Examples

Embodiment 1

[0032] In the present embodiment, the grade of the amorphous alloy is: AEM-1, and the method for rapidly smelting zirconium-based amorphous alloy master alloy thereof comprises:

[0033] (1) the niobium block is broken to obtain niobium particles with a particle size of 0.5 cm;

[0034] (2) mechanically compacting the zirconium sponge to obtain a zirconium electrode;

[0035] (3) uniformly mixing niobium particles, zirconium electrodes and remaining alloy raw materials to obtain alloy raw materials;

[0036] (4) Install the crucible in the inductor, bake and evacuate, heat through coil induction, load the power to 10kW to preheat the crucible, keep it warm for 6 hours, and the preheating temperature is 500°C;

[0037] (5) Add alloy raw materials to the crucible. All raw materials are matched in size and size. Fill the crucible with upper and lower tight mode, fill it with protective gas, load the power to 70kW, heat it through coil induction, and adjust the power in time acco...

Embodiment 2

[0040] In the present embodiment, the grade of the amorphous alloy is: AEM-1, and the method for rapidly smelting zirconium-based amorphous alloy master alloy thereof comprises:

[0041] (1) the niobium block is broken to obtain niobium particles with a particle size of 2 cm;

[0042] (2) mechanically compacting the zirconium sponge to obtain a zirconium electrode;

[0043] (3) uniformly mixing niobium particles, zirconium electrodes and alloy raw materials to obtain alloy raw materials;

[0044] (4) Install the crucible in the inductor, bake and evacuate, heat through coil induction, load the power to 20kW to preheat the crucible, keep it warm for 4 hours, and the preheating temperature is 1200°C;

[0045] (5) Add alloy raw materials to the crucible. All raw materials are matched in size and size. Fill the crucible with protective gas in the upper and lower tight mode, load the power to 30kW, heat through the coil induction, adjust the power in time according to the state of...

Embodiment 3

[0048] In the present embodiment, the grade of the amorphous alloy is: AEM-1, and the method for rapidly smelting zirconium-based amorphous alloy master alloy thereof comprises:

[0049] (1) the niobium block is broken to obtain niobium particles with a particle size of 5 cm;

[0050] (2) mechanically compacting the zirconium sponge to obtain a zirconium electrode;

[0051](3) uniformly mixing niobium particles, zirconium electrodes and alloy raw materials to obtain alloy raw materials;

[0052] (4) Install the crucible in the inductor, bake and evacuate, heat through coil induction, load the power to 10kW to preheat the crucible, keep it warm for 8 hours, and the preheating temperature is 1000°C;

[0053] (5) Add alloy raw materials to the crucible. All raw materials are matched in size and size. Fill the crucible with protective gas in the upper and lower tight mode, load the power to 50kW, and heat through the coil induction. Adjust the power in time according to the state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com